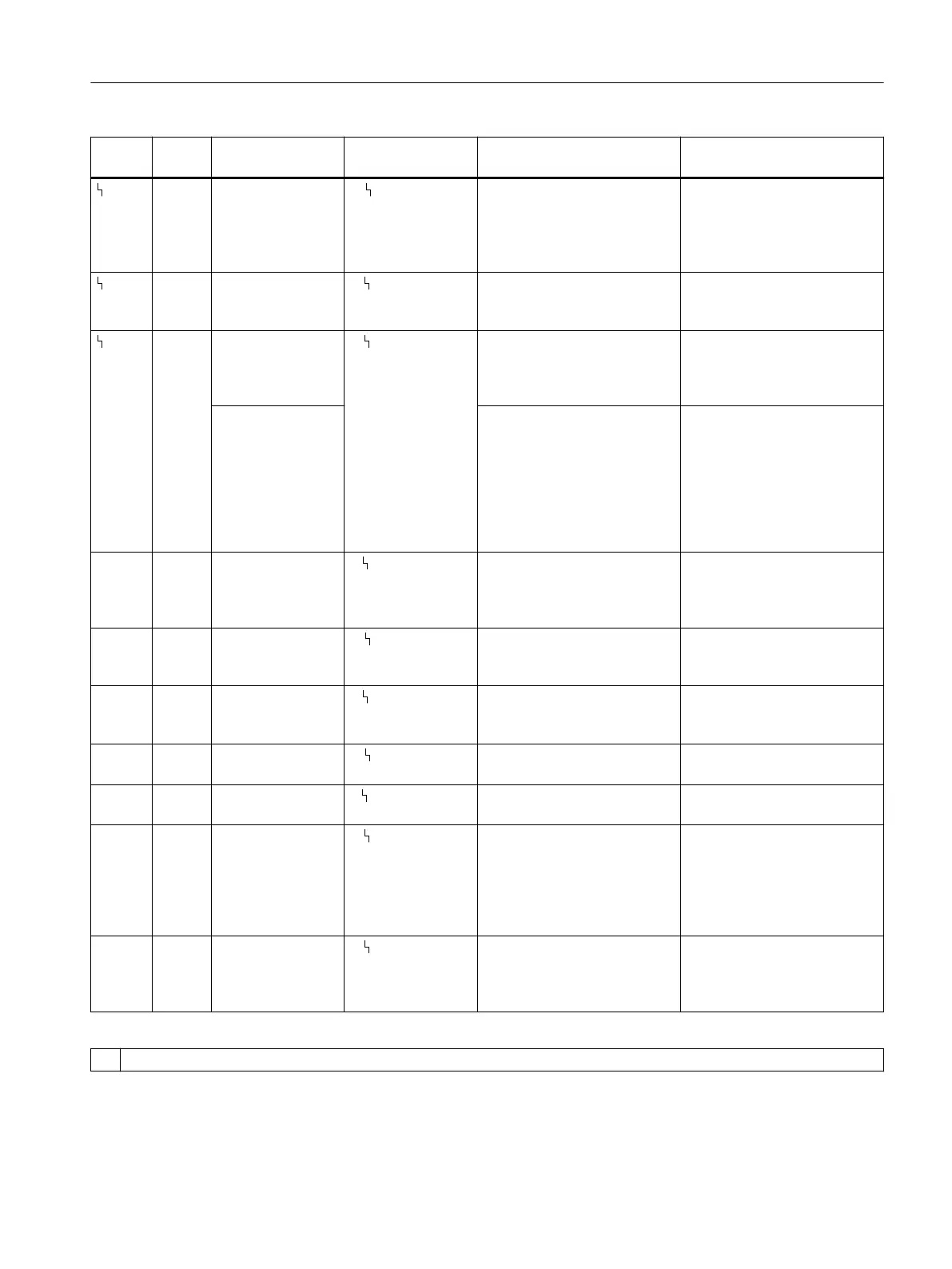

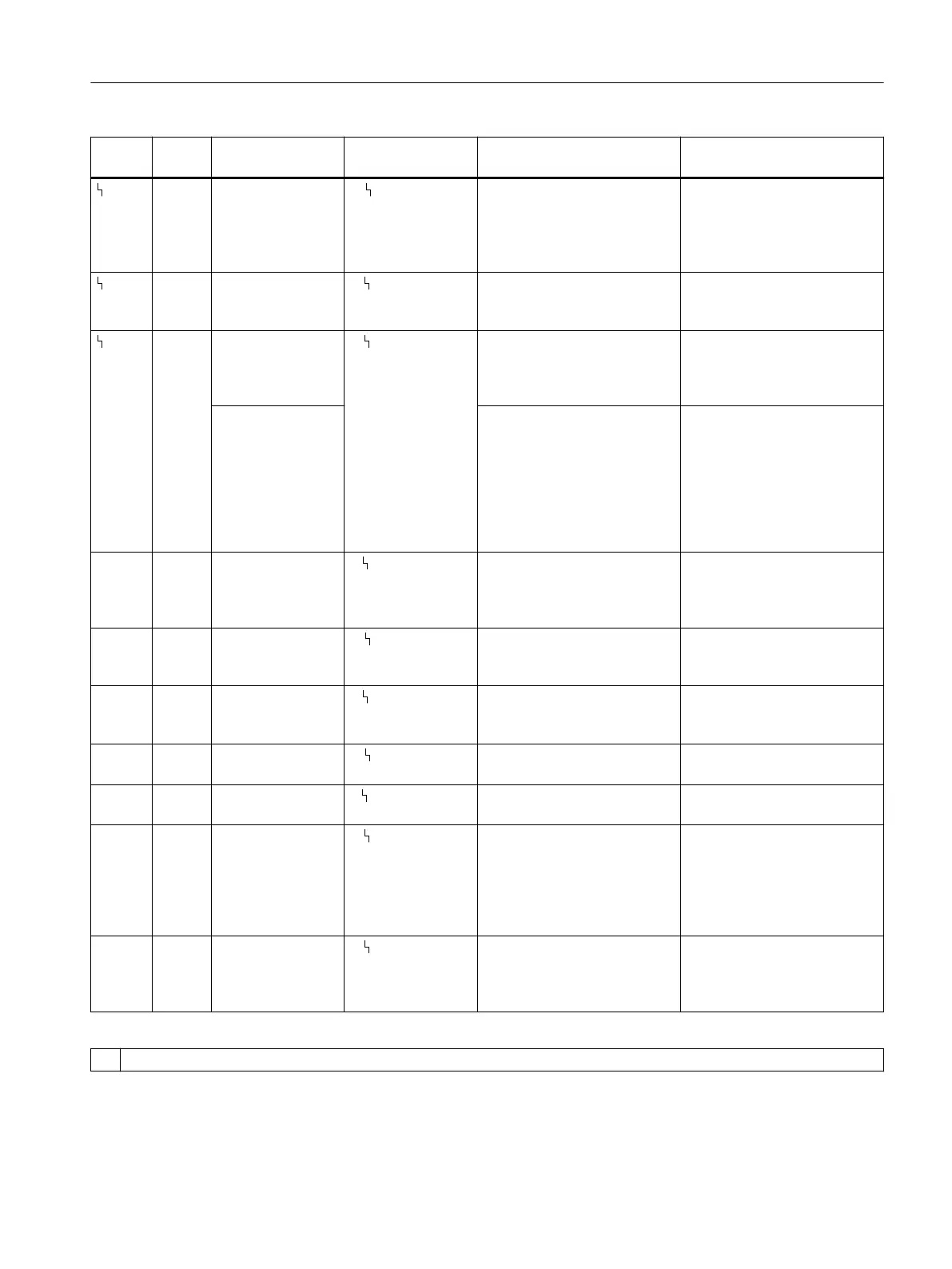

Error

code

Three-

stage

Event Parameter setting Error message disappears

when

Possible causes

7 Yes Upper endstop lim‐

it exceeded

G. OPEN≠OFF

**.YCLS

1)

= do or

up do

... the deviation of the endstop

disappears or the device is re-

initialized.

Wear and tear of the valve

seat, deposits or foreign bod‐

ies in the valve seat, mechan‐

ical misalignment, friction

clutch moved.

8 No Deadband limit ex‐

ceeded

E. DEBA≠OFF

**.DEBA

1)

= Auto

... the limit is undershot again Increased packing gland fric‐

tion, mechanical gap in the po‐

sition feedback.

9 Yes Case 1: Reference

stroke time for par‐

tial stroke test is ex‐

ceeded.

A. PST≠OFF Case 1: ... a partial stroke test

is successfully executed with‐

in the reference stroke time or

the function is deactivated.

Case 1: Valve is stuck or rus‐

ted. Increased stiction.

Case 2: Start posi‐

tion outside the

start tolerance

Case 2: Move the actuator into

the range of the PST start tol‐

erance. Or increase the PST

start tolerance until the actua‐

tor (PST start position) is with‐

in the PST start tolerance.

Start the partial stroke test

again.

Case 2: Valve is present in the

safety position.

10 Yes Deviation from ex‐

pected dynamic

control valve be‐

havior

b. DEVI≠OFF ... the position is again in a

narrow corridor between the

setpoint and the model, or the

function is deactivated.

Actuator fault, valve fault,

valve jams, increased stiction,

decreased compressed air

11 Yes Valve leakage C. LEAK≠OFF ... the valve leakage has been

remedied or the function is de‐

activated.

Pneumatic leakage

12 Yes Stiction limit (slip‐

stick) exceeded

d. STIC≠OFF ... Slipjumps can no longer be

detected, or the function is de‐

activated.

Increased stiction, valve no

longer moves smoothly but in

jerky motion.

13 Yes Temperature un‐

dershot

H. TMIN≠OFF ... the low temperature thresh‐

olds are no longer undershot.

Ambient temperature too low

14 Yes Temperature over‐

shot

J. TMAX≠OFF ... the high thresholds are no

longer overshot.

Ambient temperature too high

15 Yes Position average

deviates from the

reference value

P. PAVG≠OFF ... the average position value

calculated after a comparison

interval is again within the

thresholds for the reference

value, or the function is deac‐

tivated.

In the last comparison inter‐

val, the valve trajectory was

changed so severely that a de‐

viating average value of posi‐

tion was calculated.

16 No Partial stroke test

is to be carried out

with non-plausible

parameter values

A. PST≠OFF the parameter values entered

in A1.STPOS, A3.STRKH and

A4.STRKD are plausible.

Parameters for partial stroke

test are non-plausible

1)

Refer to the corresponding parameter descriptions for additional information about parameters

Diagnostics and troubleshooting

12.3 Online diagnostics

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 273

Loading...

Loading...