Pneumatic actuators are available in single and double-acting versions. In a single-acting

version, only one pressure chamber is ventilated and depressurized. The pressure developed

works against a spring. In a double-acting version, two pressure chambers work against each

other. Ventilating the volume of one chamber simultaneously depressurizes the volume of the

other.

Control algorithm

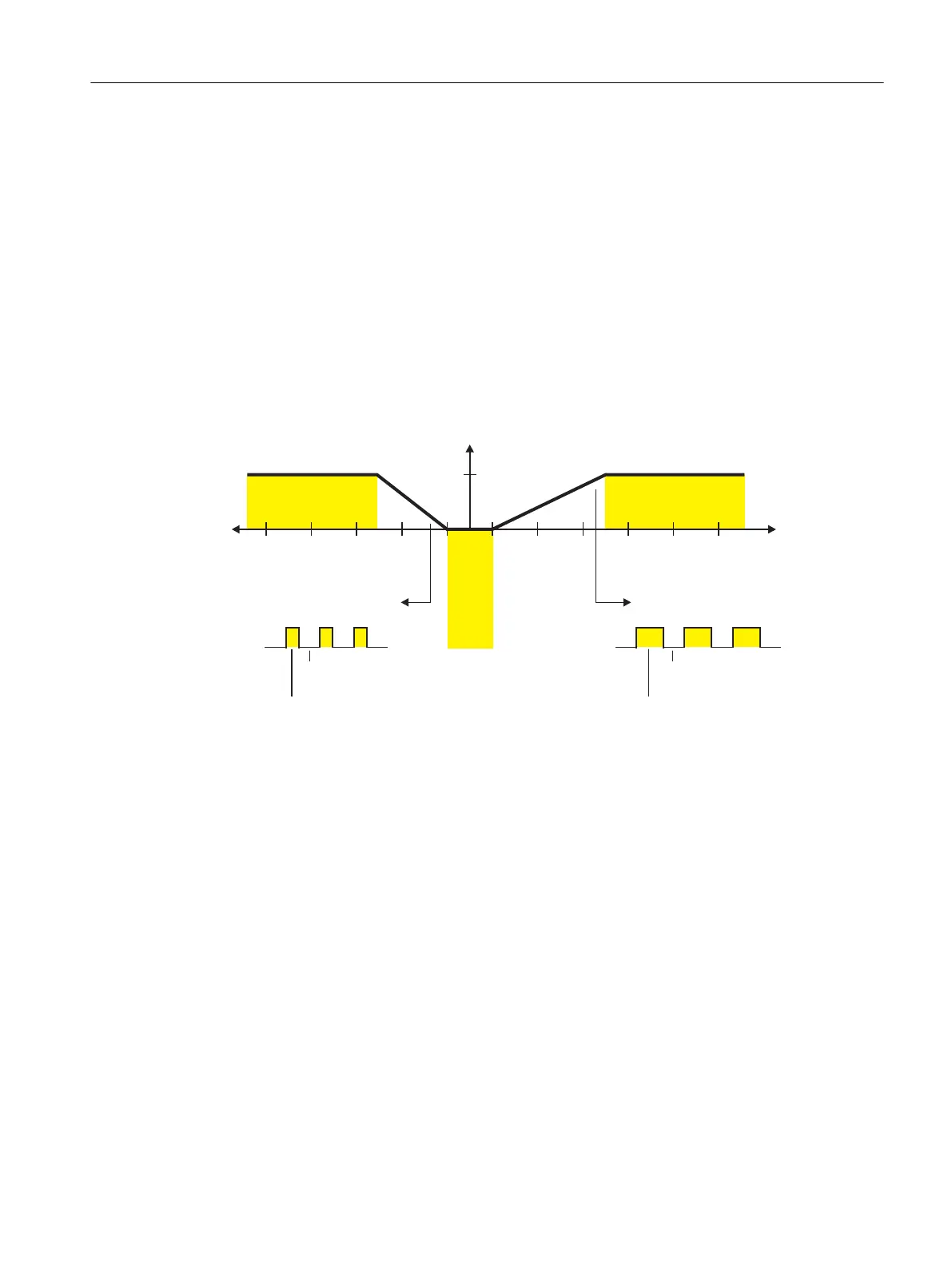

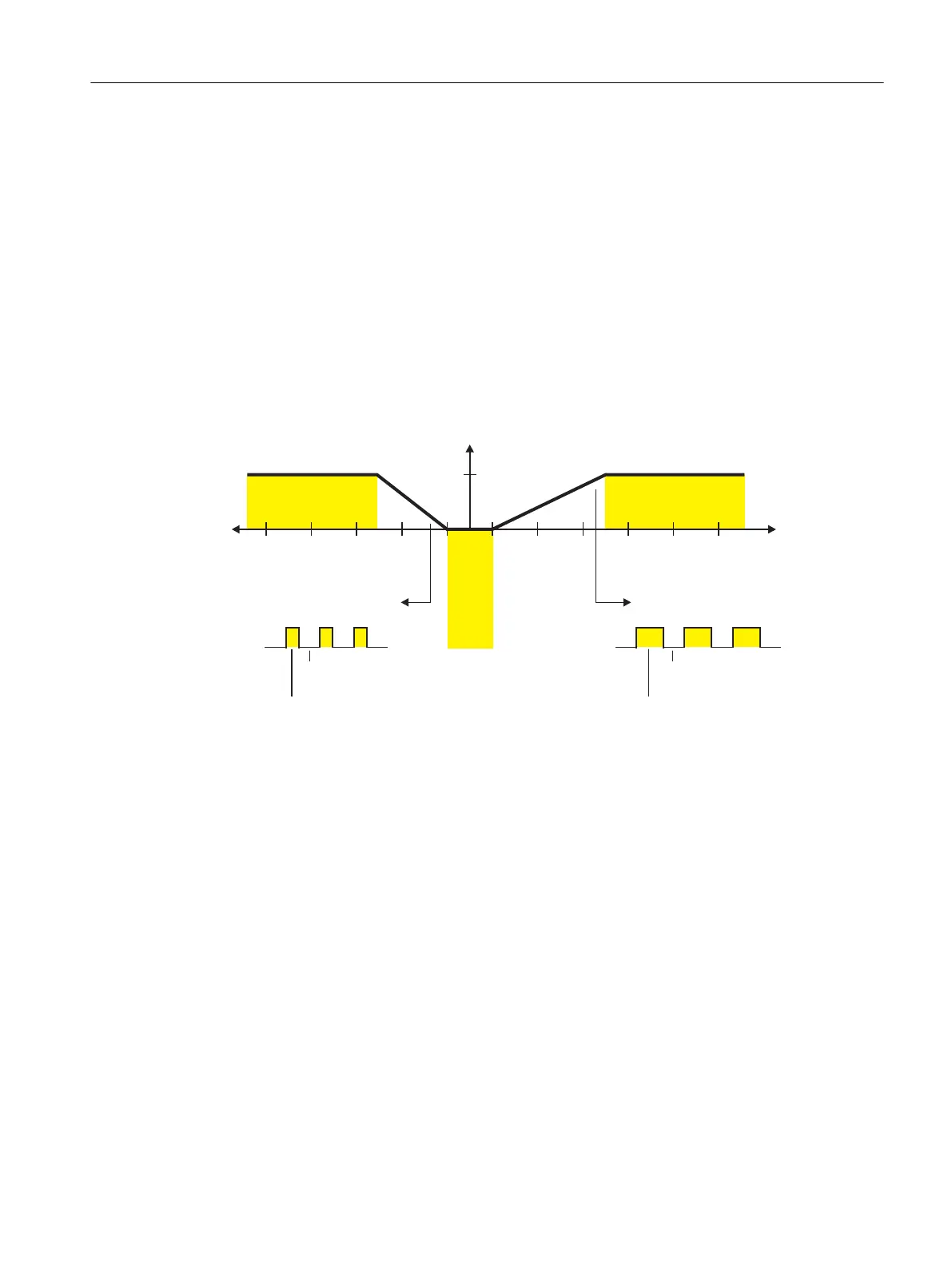

The control algorithm is an adaptive, predictive five-point controller.

In case of large control deviations, the valves are controlled using permanent contact. This

takes place in the so-called fast step zone.

In case of medium control deviations, valves are controlled using pulse-length modulated

pulses. This takes place in the so-called slow step zone.

3XOVHOHQJWK

,03'1

3XOVHSDXVH

3$873

3XOVHOHQJWK

,0383

3XOVHSDXVH

3$873

5DQJHRIQHJDWLYHFRQWUROGHYLDWLRQ

)DVWVWHS]RQH

SHUPDQHQWFRQWDFW

)DVWVWHS]RQH

SHUPDQHQWFRQWDFW

[G

9DOYHRSHQV

[G

9DOYHFORVHV

6ORZVWHS]RQH

YDULDEOHSXOVHGXW\IDFWRU

'HDGEDQG

3XOVHGXW\

IDFWRU

WR

5DQJHRISRVLWLYHFRQWUROGHYLDWLRQ

6ORZVWHS]RQH

YDULDEOHSXOVHGXW\IDFWRU

Figure 3-9 Functional principle of five-point controller

Small control deviations do not send control pulses in the zone. This takes place in the so-called

adaptive deadband. The deadband adaptation and the continuous adaptation of minimum

pulse lengths in "Automatic" mode ensure the best possible control accuracy with the smallest

number of operating cycles. The start parameters are determined during the initialization phase

and stored in the non-volatile memory. The most important start parameters are:

● The real actuator travel with end positions

● Travel times

● The deadband size

The number of fault messages, changes in direction, and the number of total strokes are

continuously determined during operation and saved every 15 minutes. You can read and

document these parameters using communication programs such as SIMATIC PDM and AMS.

By comparing the old values with the current ones, you can draw conclusions about the wear

and tear of the valve. You can use the diagnostics function for this.

Description

3.4 Functional principle

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 31

Loading...

Loading...