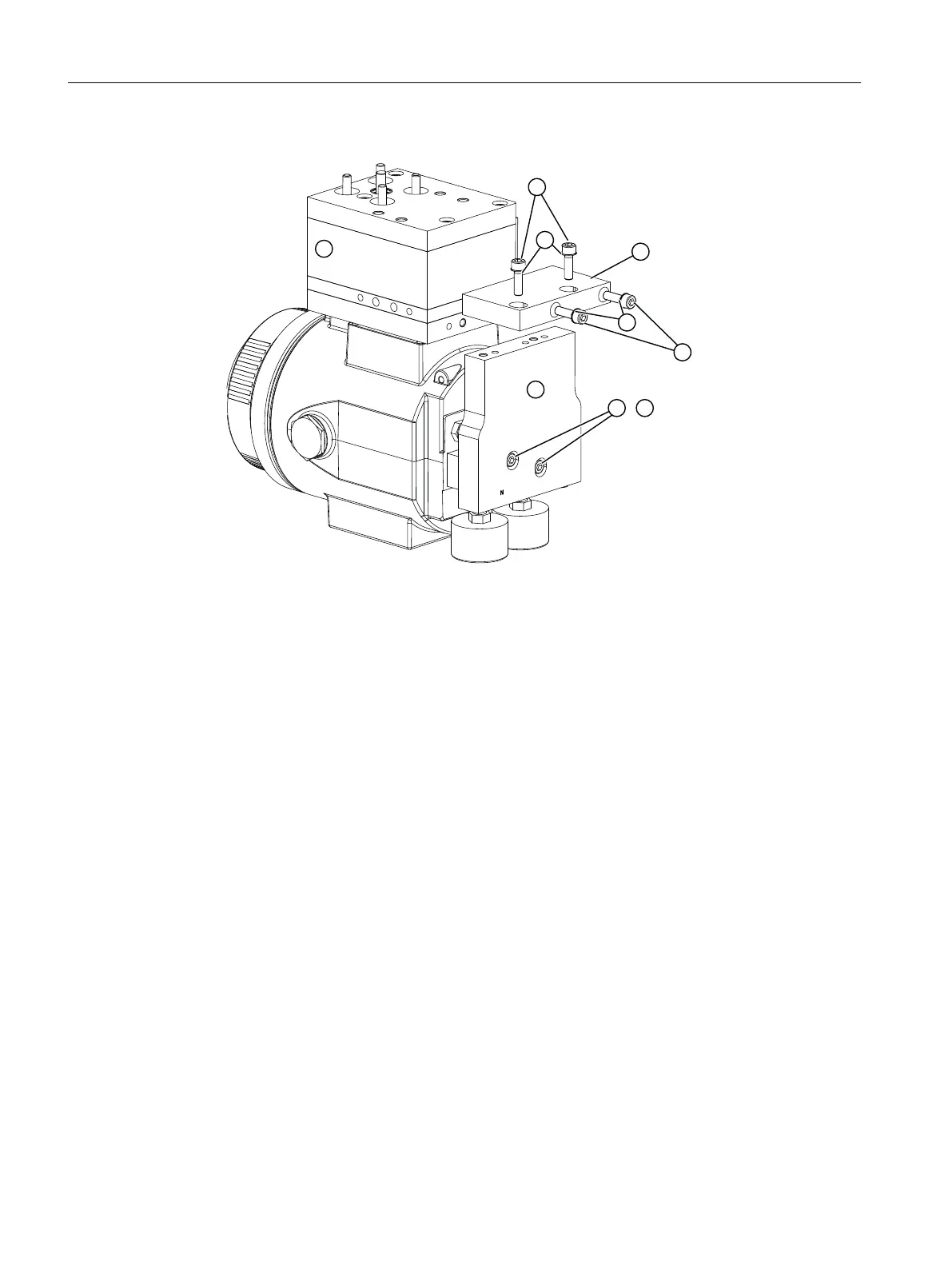

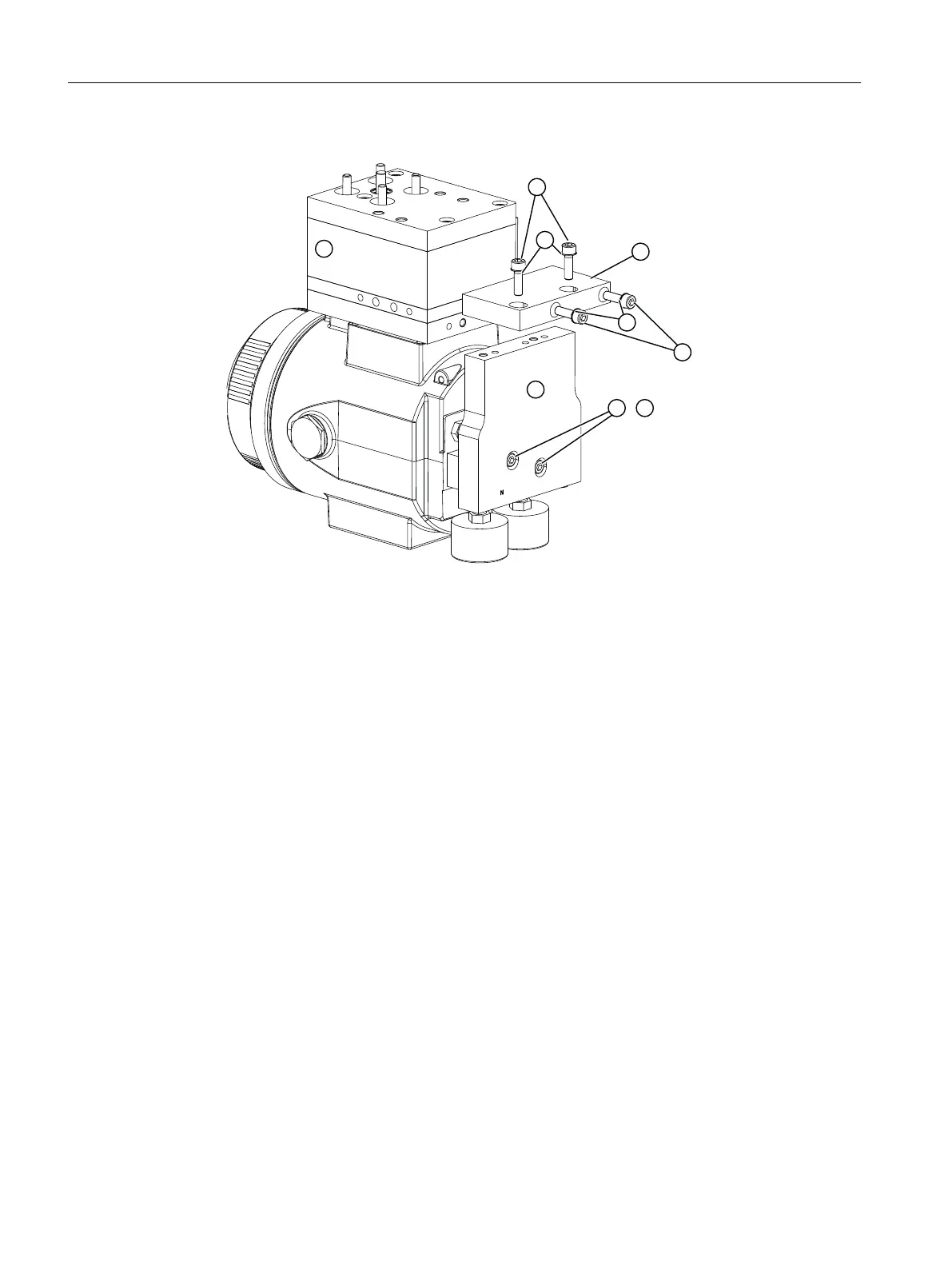

3. Apply light pressure to the lock washers ⑧. The screws are tightened later.

4. Fasten the connection block ⑨ to the booster with 2 screws ⑫ and 2 lock washers ⑬.

5. Fasten the connection block ⑨ to the manometer block ⑥ with 2 screws ⑩ and 2 lock

washers ⑪.

6. Check whether the O-rings are in the manometer block. There are two O-rings in the single-

acting version. There are three O-rings with the double-acting version.

7. Apply light pressure to the lock washers ⑬. The screws are tightened later.

C. Tighten screws

Tighten the screws in the following sequence:

1. Screws ⑦ which are used to fasten the manometer ⑥ to the positioner.

2. Screws ⑫ which are used to fasten the connection block ⑨ to the booster.

3. Screws ⑩ which are used to fasten the connection block ⑨ to the manometer ⑥.

4. Mount the positioner on the actuator as described in:

– Mounting to linear actuator (Page 42)

– Mounting to part-turn actuator (Page 47)

5. Use the existing interfaces on the booster.

Booster

E.5 Booster mounting, flameproof enclosure

SIPART PS2 with PROFIBUS PA

344 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...