Section 04 TRANSMISSION

Sub-Section 04 (DRIVEN PULLEY)

04-04-2

NOTE :

Driven pulley components (support,

cam, shoes, etc.) can be serviced without re-

moving the whole driven pulley from chaincase.

Refer to the following procedures but neither re-

move brake caliper nor open chaincase for those

cases.

REMOVAL

To remove driven pulley from chaincase, follow

this procedure.

Remove belt guard and drive belt from vehicle.

Remove brake support

no. 13

from chaincase

with brake ass’y.

Free countershaft support

no. 1

from support

clamp.

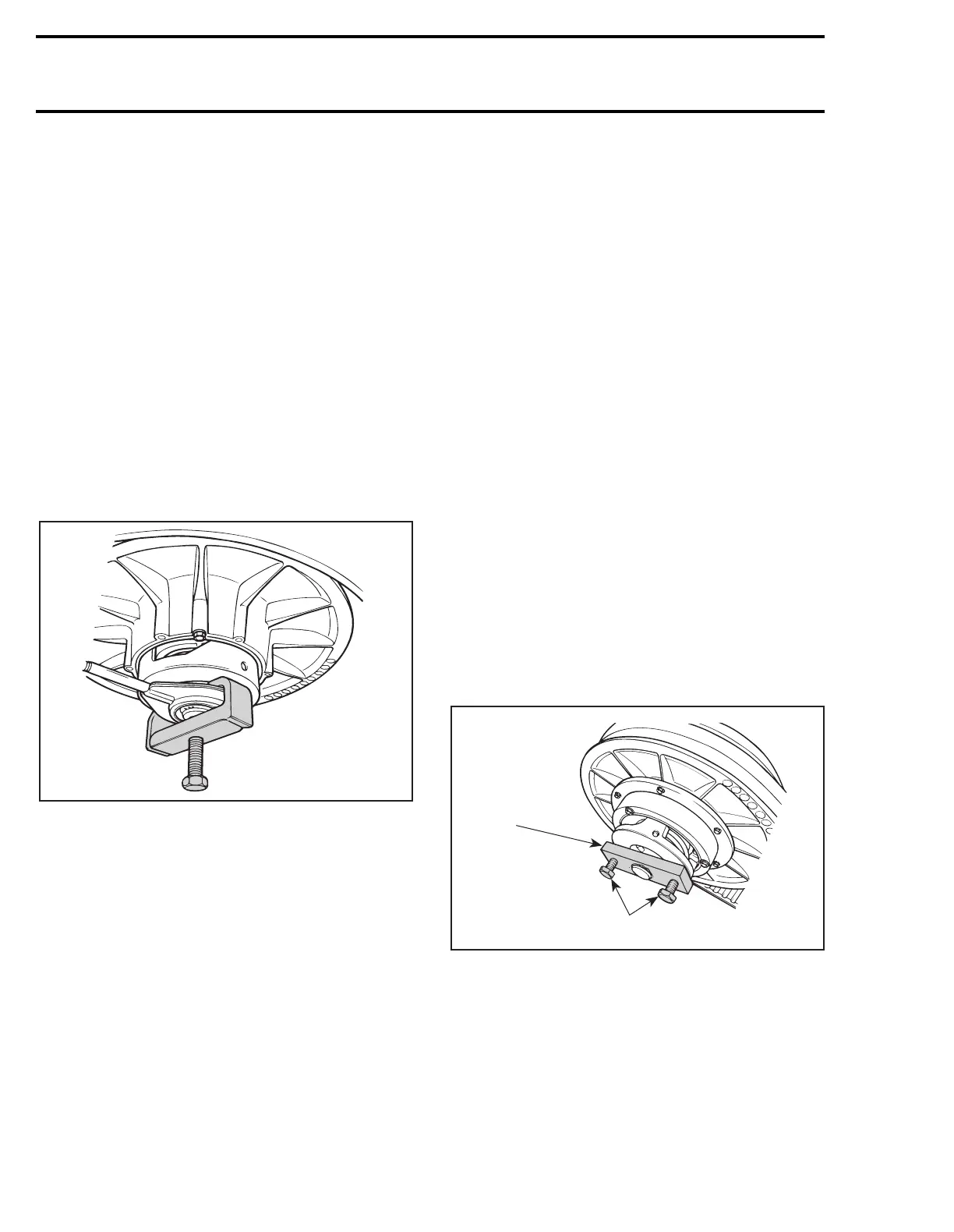

To remove driven pulley support use support pull-

er (P / N 529 0135 00).

Chaincase

Open chaincase and drain oil. Unlock and remove

upper sprocket.

The following is required to have enough space to

remove driven pulley from chaincase :

Slacken upper retaining screws of steering col-

umn.

Disconnect carburetor boots from intake manifold

and air intake silencer.

Disconnect impulse hose from engine.

Disconnect oil injection supply line at injection

pump and plug line to prevent draining.

Remove screws retaining rear engine support to

chassis.

Tip engine forward just enough to allow driven

pulley removal from chaincase. Block in this posi-

tion.

NOTE :

In some cases, chaincase retaining

screws might have to be slackened to allow

pivoting of chaincase. In this case, note position

of alignment shims. Besides, air intake silencer

and oil injection reservoir might have to be slightly

moved to get enough space to pull driven pulley.

DISASSEMBLY

Chaincase and Driven Pulley

Remove bearing cone.

Knock driven pulley shaft with a plastic hammer

and pull driven pulley out.

Remove support

no. 1

using a suitable puller.

Remove roll pin

no. 2

and slide outer cam

no. 4

out of pulley shaft.

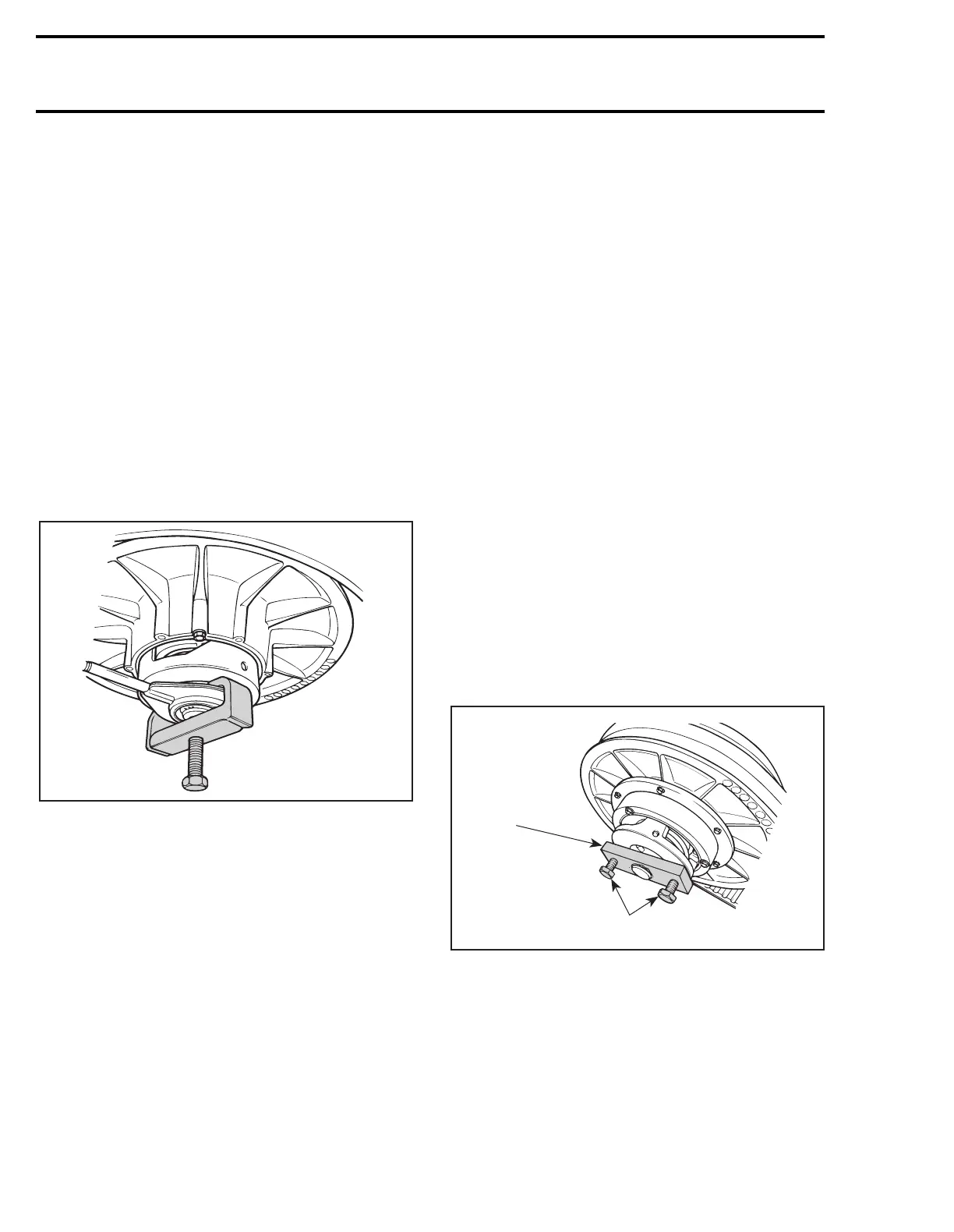

Install tool (P / N 529 0129 00), reinstall washer,

lock washer and screw. Tighten tool screws alter-

nately then remove roll pin.

1. Tighten alternately

Note spring original setting (adjusting hole in slid-

ing half).

A25B0GA

529 0135 00

'

A18B07A

529 0129 00

1

Loading...

Loading...