Section 04 TRANSMISSION

Sub-Section 03 (DRIVE PULLEY)

04-03-6

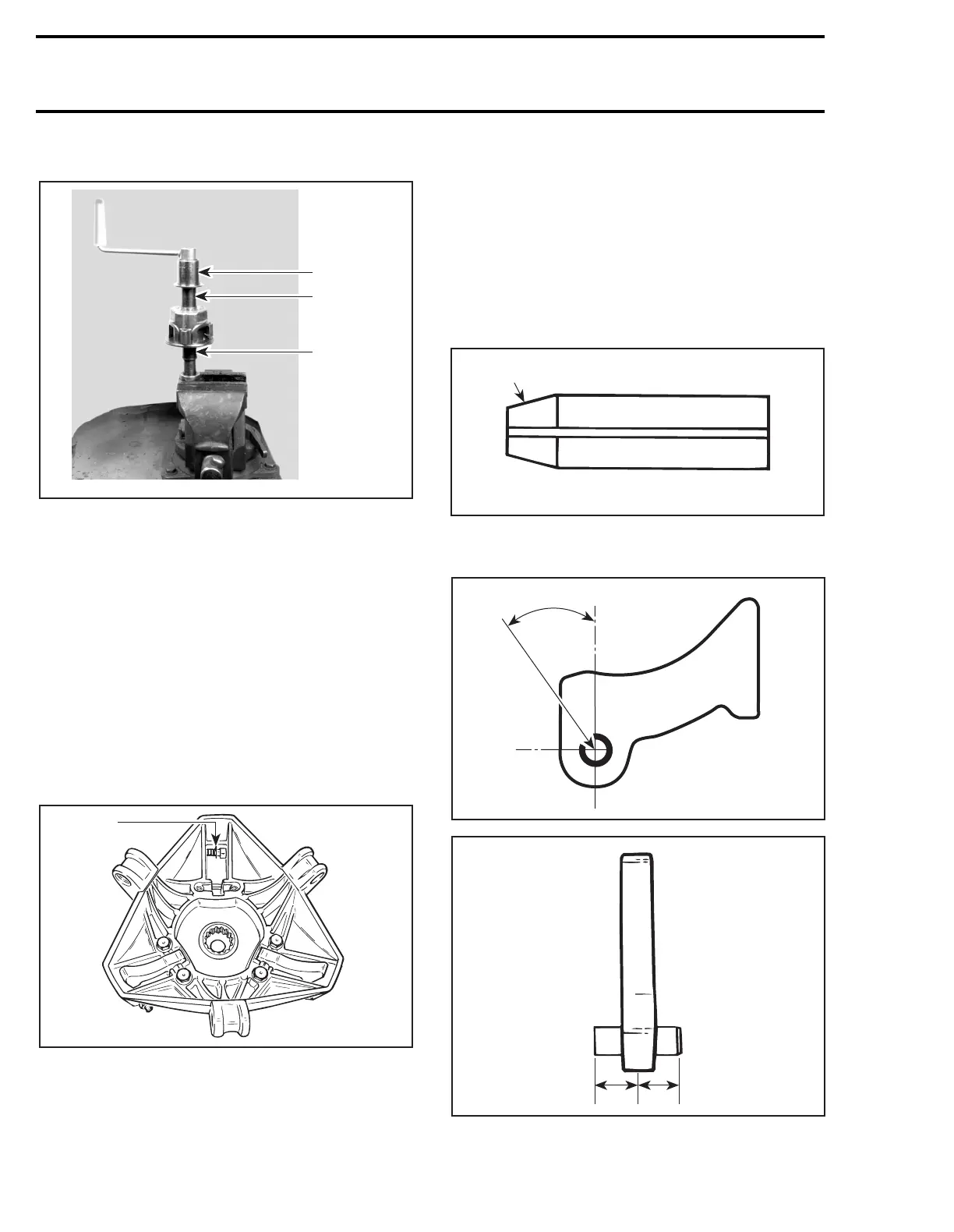

Press bushing.

1. Note upper tool side.

ASSEMBLY

NOTE:

This drive pulley is lubrication free.

Do not lubricate

any component.

1,2,3, Screw, Ring Gear and Loctite 271

Apply Loctite 271 (P/N 413 7029 00) on threads

and then torque to 27 N•m (20 lbf•ft).

26,27,28, Calibration Screw, Washer

and Locking Nut

When installing calibration screw, make sure to in-

stall washer as shown.

1. Washer

Torque locking nut to 10 N•m (89 lbf•

in

).

15, Pin

Always use the same type of pin as originally in-

stalled when servicing. Different types have dif-

ferent weights for calibration purpose. Refer to

TECHNICAL DATA 09-03.

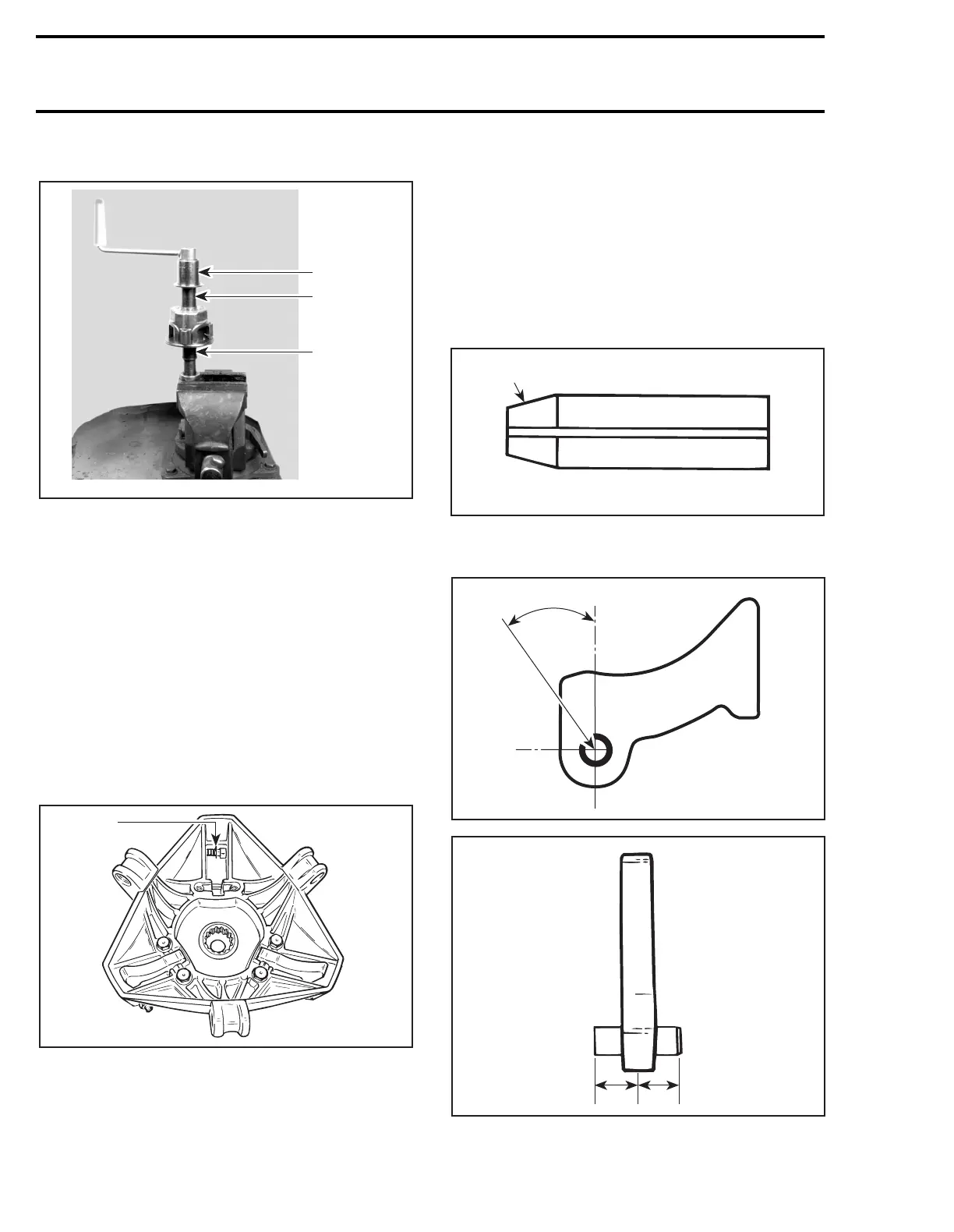

21,22,23, Ramp, Dowel Tube and Screw

Insert dowel tube from chamfered side. Make

sure ramp is centered on dowel tube.

1. Chamfered side

Position dowel tube split at the illustrated angle.

1. Equal distance

Torque screws to 10 N•m (89 lbf•

in

).

A01D2OA

529 0313 00

529 0312 00

1

'

A16D07A

1

A16D08A

1

A16D2PA

30 ± 5°

A16D09A

11

Loading...

Loading...