Section 03 ENGINE

Sub-Section 04 (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

03-04-6

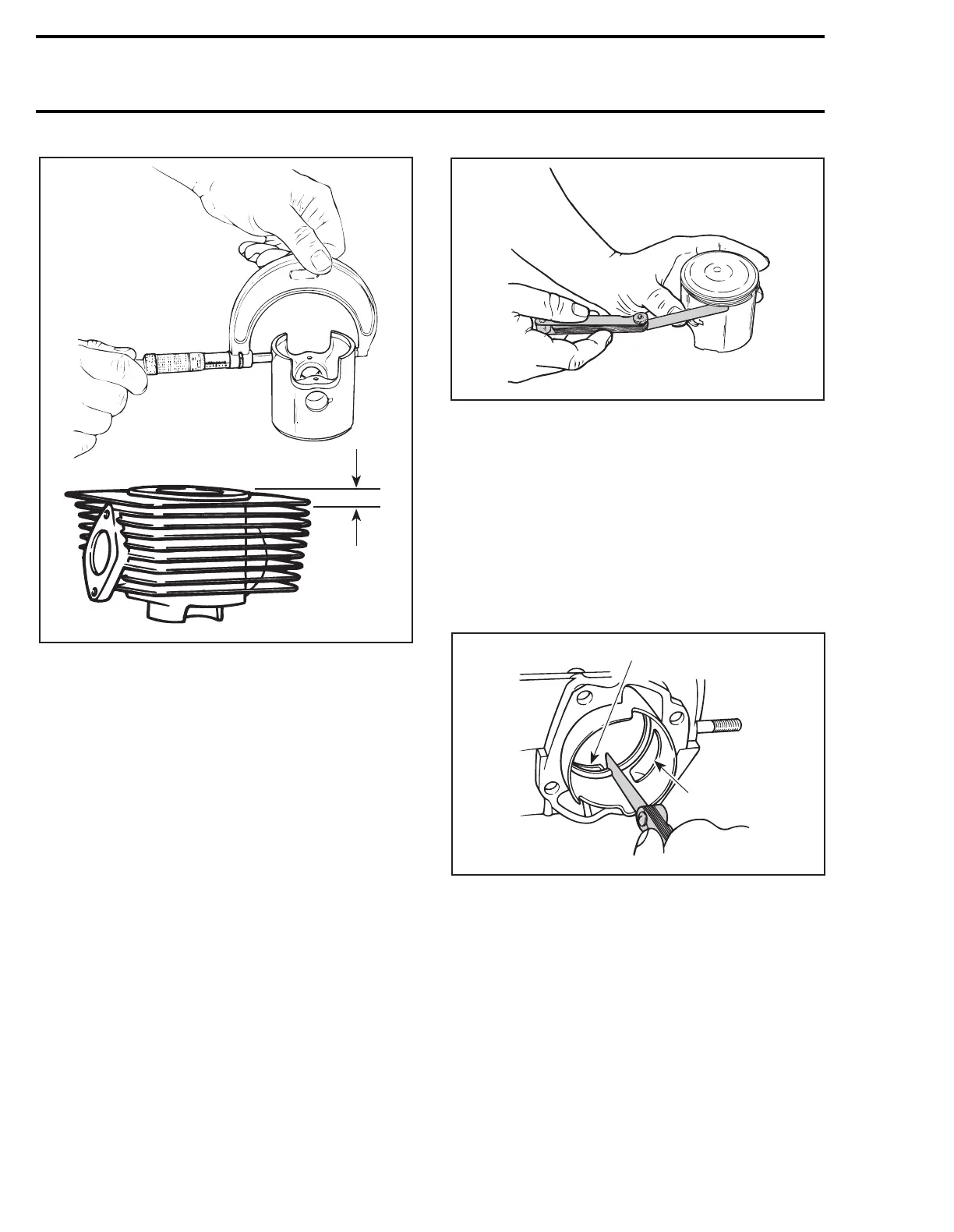

A. 16 mm (5/8 in)

The difference between these 2 measurements

should be within specified tolerance. Refer to

TECHNICAL DATA 09-02.

Measurement (fitting new parts)

With an inside micrometer, measure cylinder di-

ameter above the exhaust port.

With a micrometer, measure the piston diameter

perpendicularly (90°) to piston axis and 3 mm (1/8

in) above bottom edge.

The difference of both measurements is the clear-

ance.

RING / PISTON GROOVE

CLEARANCE

Using a feeler gauge check clearance between

rectangular ring and groove. Replace piston. If

clearance exceeds specified tolerance. Refer to

TECHNICAL DATA 09-02.

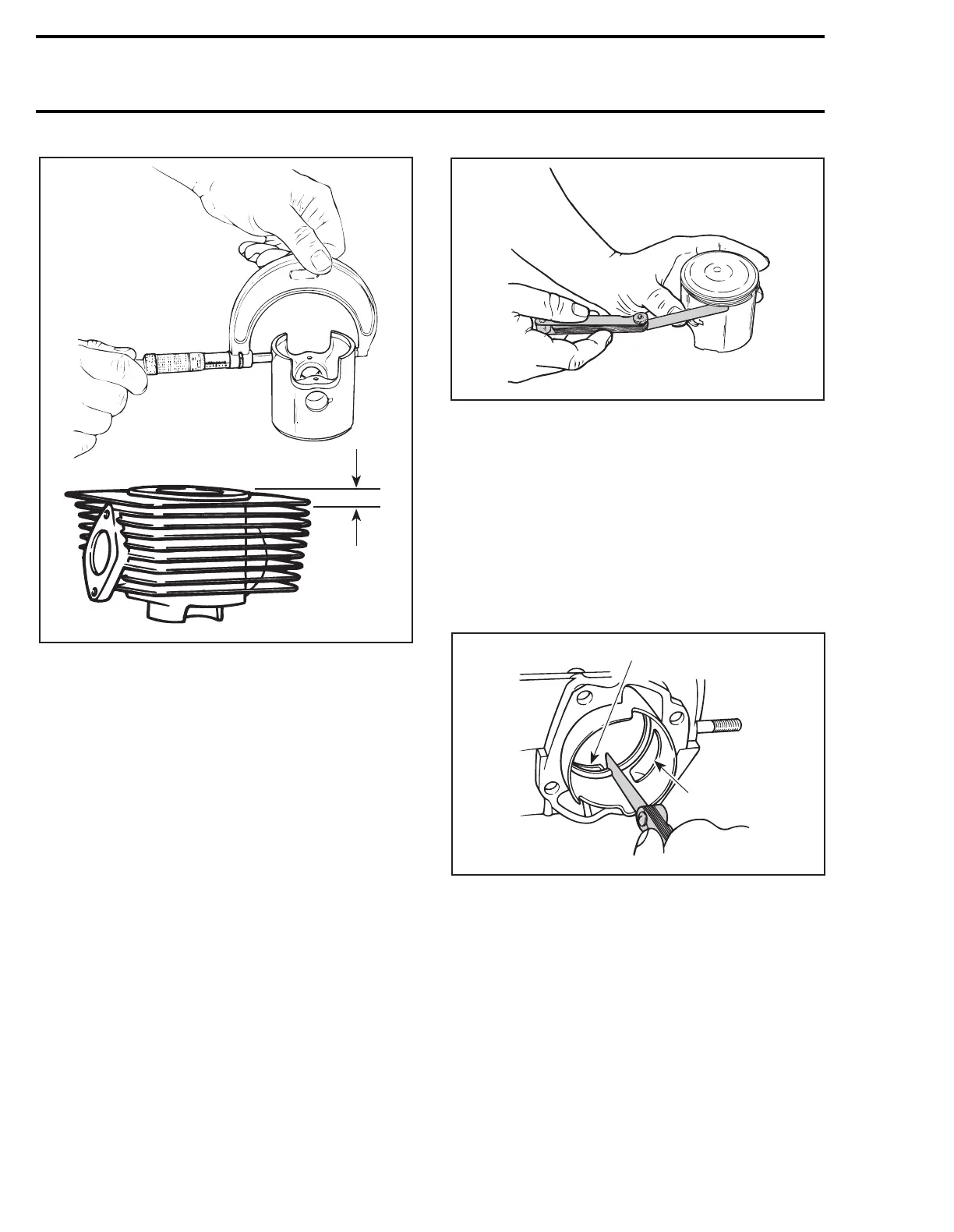

RING END GAP

Position ring half way between transfer ports and

intake port. On rotary valve engines, position ring

just below transfer ports.

NOTE :

In order to correctly position the ring

in the cylinder, use piston as a pusher.

Using a feeler gauge, check ring end gap. Replace

ring. If gap exceeds specified tolerance, refer to

TECHNICAL DATA 09-02.

1. Transfer port

2. Intake port

CRANKSHAFT DEFLECTION

Crankshaft deflection is measured with a dial indi-

cator.

Measuring (In Engine)

First, check deflection with crankshaft in engine.

If deflection exceeds the specified tolerance, re-

check deflection using V-shaped blocks to deter-

mine the defective part(s). See below.

A

A01C55A

A01C0PA

A01C0QA

2

1

Loading...

Loading...