Section 03 ENGINE

Sub-Section 11 (CARBURETOR AND FUEL PUMP)

03-11-3

DISASSEMBLY AND ASSEMBLY

NOTE:

To ease the carburetor disassembly

and assembly procedures it is recommend-

ed to use carburetor tool kit (P/N 404 1120 00).

2,3, E-clip and Needle

Remove screws from needle retaining plate to

withdraw the needle.

The position of the needle in the throttle slide is

adjustable by means of an E-clip inserted into 1 of

5 grooves located on the upper part of the needle.

Position 1 (at top) is the leanest, 5 (at bottom) the

richest.

NOTE:

The last digit of the needle identifica-

tion number gives the recommended posi-

tion of the E-clip

from the top

of the needle.

CLIP POSITIONS

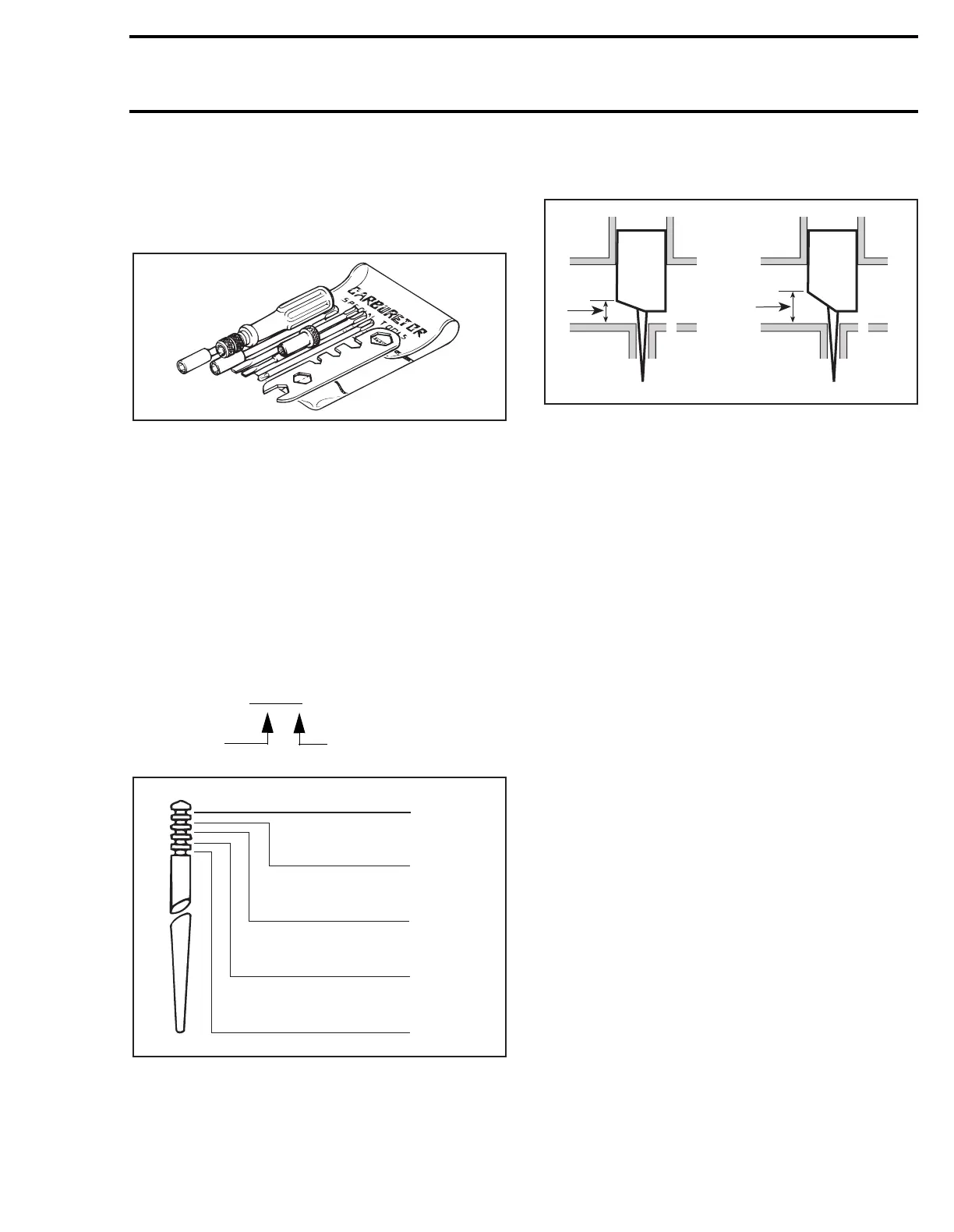

The size of the throttle slide cut-away affects the

fuel mixture between 1/8 to 1/2 throttle opening.

1. Low cut-away low

2. Rich mixture

3. High cut-away high

4. Lean mixture

8, Main Jet

The main jet installed in the carburetor has been

selected for a temperature of -20°C (0°F) at sea

level. Different jetting can be installed to suit tem-

perature and/or altitude changes. Always check

spark plug tip and/or piston dome color to find out

correct jetting.

CARBURETOR FLOAT LEVEL

ADJUSTMENT

9,10, Float Arm and Float Arm Pin

Correct fuel level in float chamber is vital toward

maximum engine efficiency. To check for correct

float level proceed as follows:

– Make sure that float arm is symetric — not dis-

tored.

– Remove float bowl and gasket from carburetor.

– With carburetor chamber upside-down on a lev-

el surface, measure height H between bowl

seat and

top

edge of float arm. Keep ruler per-

fectly vertical and in line with main jet hole.

Example: 6DH4-3

Needle

identification

Recommended position.

of the E-clip from top

'

A00B2FA

'

A00B2GA

1

2

3

4

5

Lean

Rich

1

3

2

4

A00C01A

Loading...

Loading...