Section 03 ENGINE

Sub-Section 04 (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

03-04-6

ENGINE DIMENSION MEASUREMENT

This section covers all engine types.

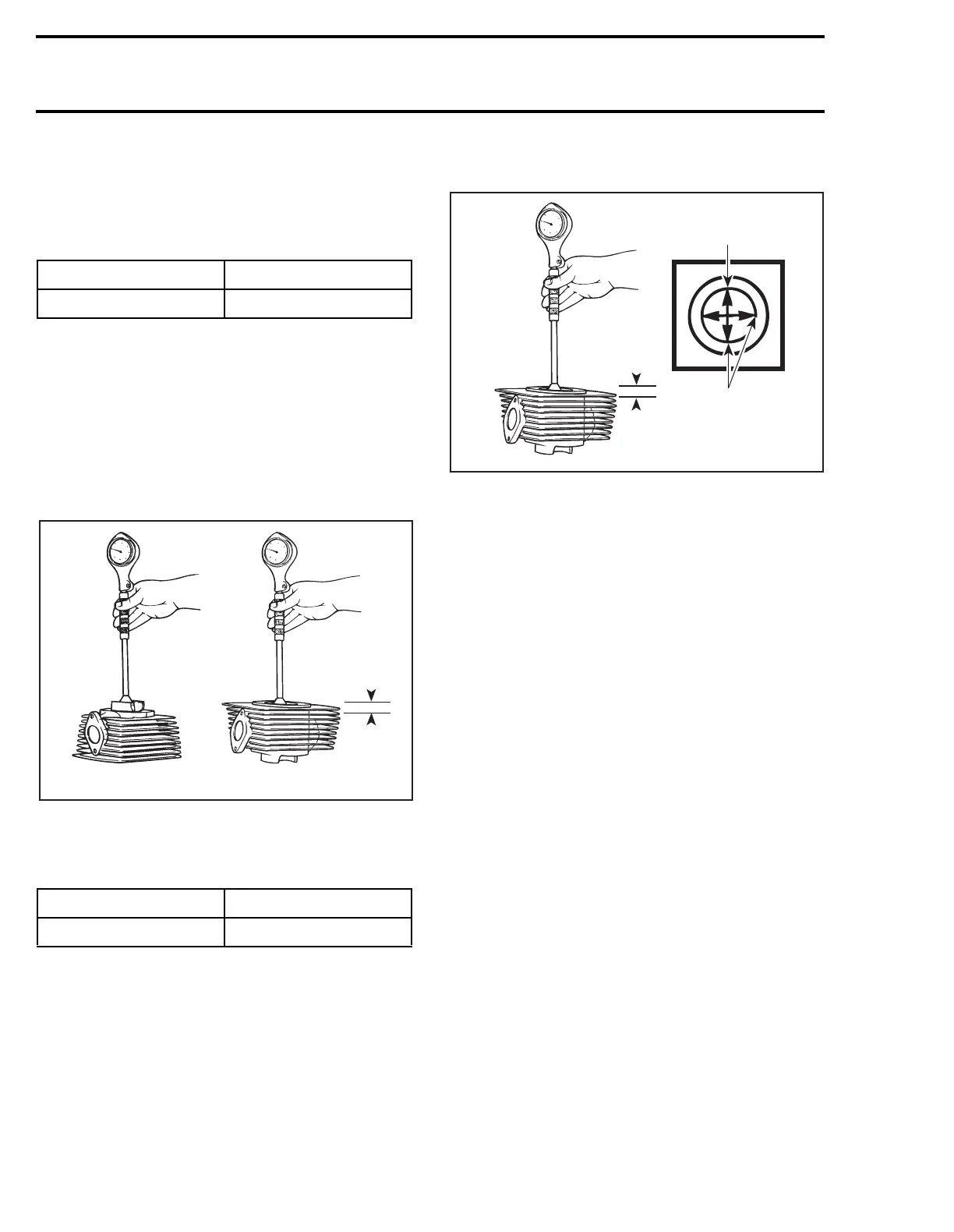

CYLINDER TAPER

Compare cylinder diameter 16 mm (5/8 in) from

top of cylinder to just below its intake port area.

On rotary valve engines, measure just below aux-

iliary transfer port, facing exhaust port. If the dif-

ference exceeds the specified dimension the

cylinder should be rebored and honed or should

be replaced.

NOTE:

Be sure to restore the chamfer

around all cylinder sleeve port openings.

1. Below the intake port

A. 16 mm (5/8 in) from top

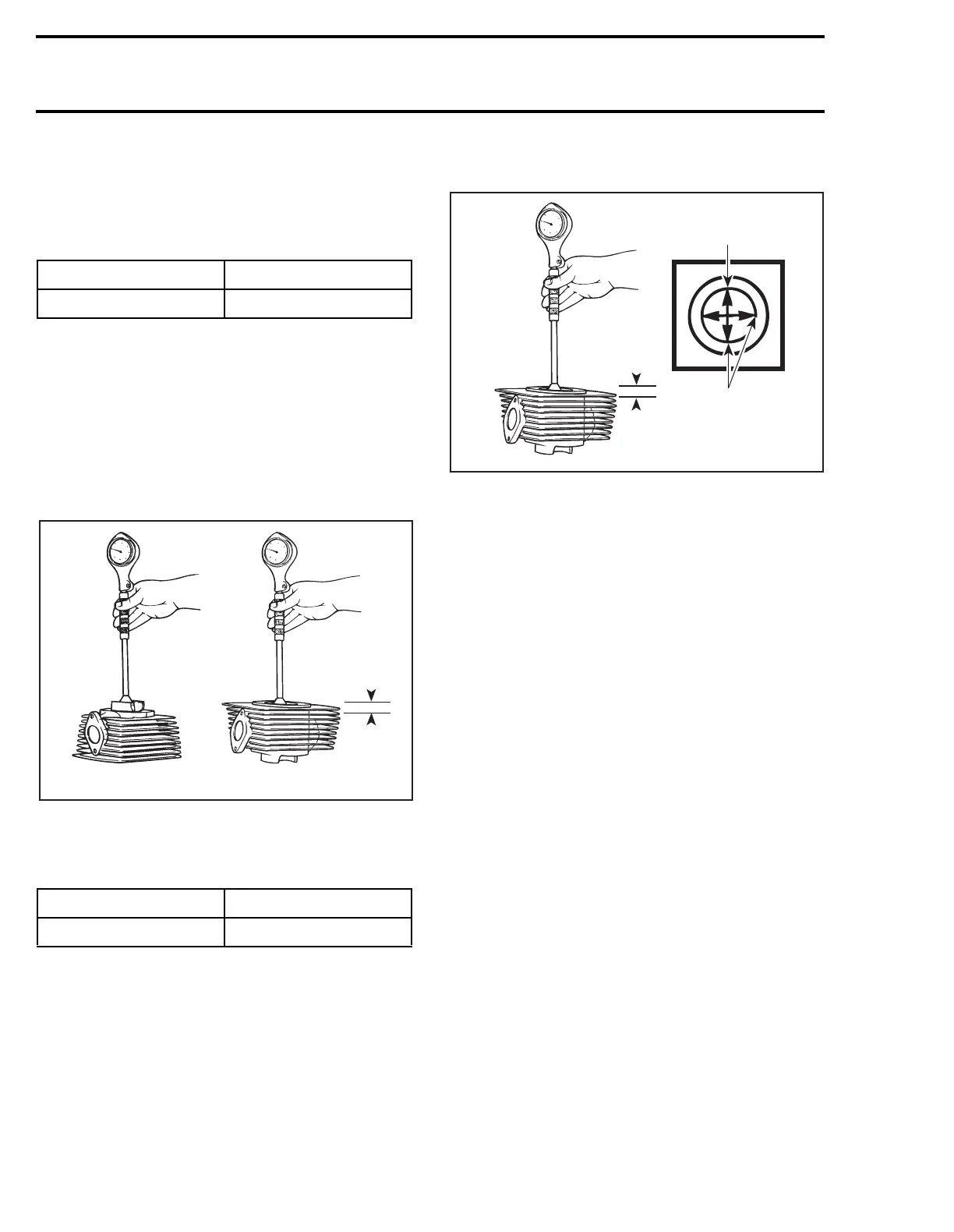

CYLINDER OUT OF ROUND

Measuring 16 mm (5/8 in) from top of cylinder

with a cylinder gauge, check if the cylinder out of

round is more than the specified dimension. If

larger, cylinder should be rebored and honed or

should be replaced.

NOTE:

Be sure to restore the chamfer

around all cylinder sleeve port openings.

1. Piston pin position

2. Measures to be compared

A. 16 mm (5/8 in)

CYLINDER/PISTON CLEARANCE

Measurement (used parts)

Check cylinder taper and out-of-round as described

above before proceeding with piston/cylinder clear-

ance.

To accurately determine piston to cylinder clear-

ance, the piston should be measured under the

axis hole and 90° to piston pin axis. Find the big-

gest diameter.

The cylinder should be measured 16 mm (5/8 in)

below its top edge. Find the smallest diameter.

ENGINE TYPE MAXIMUM

All 0.08 mm (.003 in)

ENGINE TYPE MAXIMUM

All 0.05 mm (.002 in)

A01C53A

1

A

A01C54A

2

1

A

Loading...

Loading...