Section 04 TRANSMISSION

Sub-Section 04 (DRIVEN PULLEY)

04-04-5

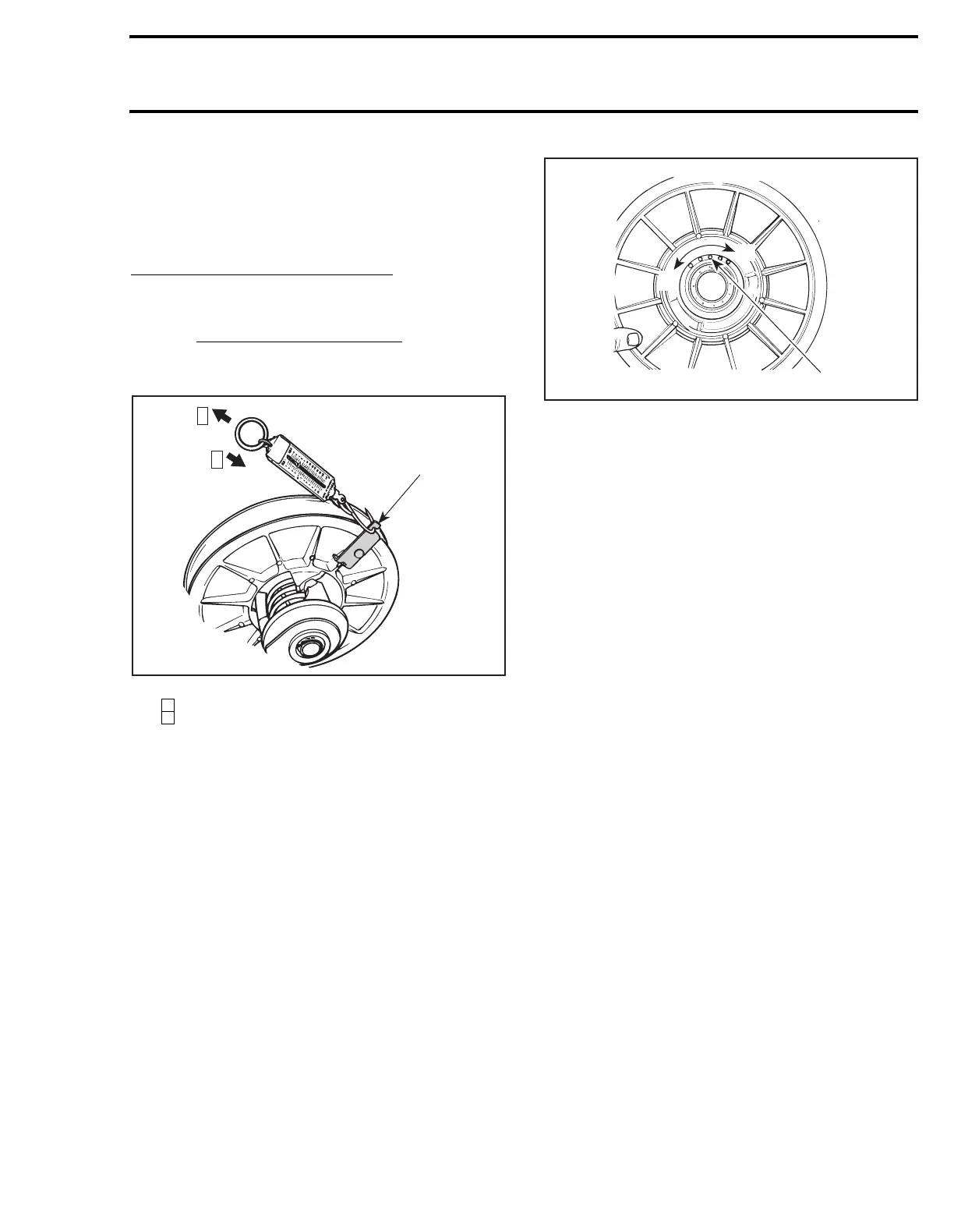

Take a measurement when opening driven pulley

and another one when driven pulley begins to close

after a rotation of 10 mm (3/8 in). Spring pre-load

is the average measurement between these 2.

TYPICAL

Step : 1

st

measurement

Step : 2

nd

measurement

Spring pre-load should be as TECHNICAL DATA

section 09.

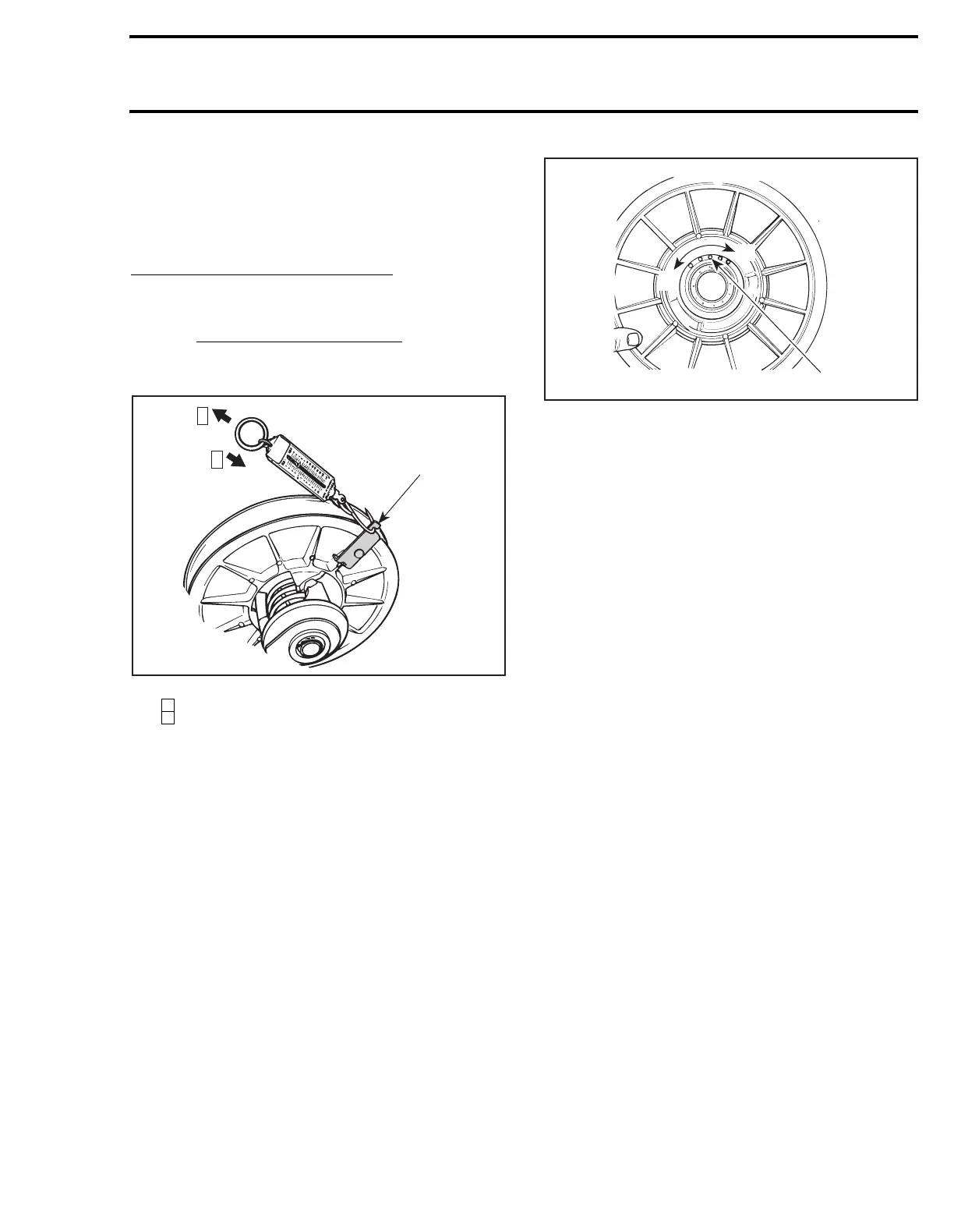

To adjust spring pre-load relocate spring end in

sliding pulley, moving it clockwise to decrease the

pre-load and counterclockwise to increase it.

1. Decrease

2. Adjusting holes

3. Increase

NOTE :

Always recheck torsional pre-load

after adjusting.

Chaincase

Check oil level and refill as required. Refer to

CHAINCASE 04-07.

Pulley Alignment and Drive Belt

Deflection

Refer to PULLEY DISTANCE AND ALIGNMENT

04-05 and DRIVE BELT 04-02 to perform adjust-

ments.

CAUTION : Drive belt and pulley adjust-

ments must always be checked whenever

pulleys have been removed, replaced or disas-

sembled.

1

st

measurement

(when opening)

+

2

nd

measurement

(when closing)

=

Spring

pre-load

2

Example :

3.8 kg (8.4 lb)

(when opening)

+

3.4 kg (7.9 lb)

(when closing)

=

3.6 kg (8 lb)

Actual

spring

pre-load

2

529 0065 00

A01B18A

1

2

1

2

A07D0CB

1

2

3

2

1

Loading...

Loading...