Why is the display flashing on my SMC Networks Switch?

- SStephanie RobbinsSep 12, 2025

If the display on your SMC Networks Switch flashes, it suggests there may be incorrect wiring. Check and correct the wiring to resolve this issue.

Why is the display flashing on my SMC Networks Switch?

If the display on your SMC Networks Switch flashes, it suggests there may be incorrect wiring. Check and correct the wiring to resolve this issue.

Why can't I change the display measurement unit on my SMC Networks PF3A801H-L?

If the display measurement unit on your SMC Networks Switch cannot be changed, it may be because the selected model does not have a unit conversion function. The unit selection function is not available for models fixed to SI units. If this is not the issue, consider replacing the product.

| Number of Ports | 8 |

|---|---|

| Power over Ethernet (PoE) | No |

| Switching Capacity | 16 Gbps |

| Forwarding Rate | 11.9 Mpps |

| Weight | 0.7 kg |

| MAC Address Table | 8K entries |

| Throughput | 11.9Mpps |

| Port Type | Gigabit Ethernet |

| Dimensions | 28 mm x 220 mm x 130 mm |

| MAC Address Table Size | 8K entries |

| Status Indicators | Link/Activity |

| Ports | 8 x 10/100/1000Base-T |

Defines hazard levels (Caution, Warning, Danger) used in safety instructions.

Outlines essential safety measures and precautions for product operation and handling.

Details product usage guidelines, warranty terms, and compliance requirements.

Lists critical warnings regarding disassembly, operation outside specifications, and hazardous environments.

Provides precautions for handling the product, including electrical safety and environmental considerations.

Essential guidelines for safely handling the product, including avoiding shock and damage.

Specifies correct mounting procedures, including torque, orientation, and avoiding vibration.

Guides users through initial setup, operation sequence, and parameter adjustments.

Explains the structure of the product model number for correct identification.

Lists available accessories and their corresponding part numbers for ordering.

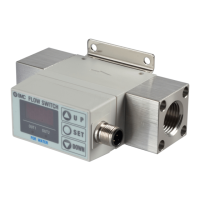

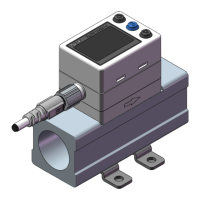

Identifies the main body components and details the connector pin assignments.

Provides descriptions of individual components like display, connector, and piping ports.

Describes the main display, sub display, operation LED, and control buttons.

Explains the function and meaning of the IO-Link status indicator light.

Details the meaning of IO-Link status indicator lights and screen messages during communication.

Defines technical terms from Accumulated flow to Error display.

Defines technical terms from F.S. to Normal condition.

Defines technical terms from Operating mode to Repeatability.

Defines technical terms from Set point range to Zero-clear function.

Guides on correct mounting orientation and how to rotate the display for optimal visibility.

Indicates the direction of fluid flow on the product body.

Details the procedure for installing piping and the required tightening torque for screws.

Lists available options for connecting modular units and adapters.

Warns about moment loads on piping and suggests support measures to prevent damage.

Provides step-by-step instructions for connecting and disconnecting electrical wires and connectors.

Specifies pin assignments for switch outputs and IO-Link communication.

Illustrates the internal circuitry for NPN and PNP output types.

Provides practical wiring examples for accumulated pulse output and IO-Link device configuration.

Describes the primary mode for measurement, display, and switch function operation.

Details how to navigate to different setting modes for configuration.

Explains the 3-step mode for adjusting set values and hysteresis simply.

Provides the factory default settings for set values and hysteresis for different models.

Guides on operating the hysteresis mode to set values and hysteresis using buttons.

Describes settings for window comparator and accumulated output modes within the 3-step setting.

Details how to adjust set value, hysteresis, and delay time using the simple setting mode.

Describes using the simple mode for window comparator and accumulated output configurations.

Introduces the function selection mode for configuring individual parameters (F0-F99).

Provides a table of default settings for all configurable functions (F0 to F99).

Defines standard and normal conditions for measurement reference.

Details settings for units, switch output type, output object selection, and display color.

Guides on setting the reference condition and selecting display units.

Covers selection of switch output type (NPN/PNP) and output object (OUT1/OUT2).

Describes how to select the display color for the main screen.

Explains various switch output modes like Hysteresis, Window Comparator, Accumulated, Error, and OFF.

Details how to select the target parameter (Flow, Temp, Pressure, etc.) for OUT1 settings.

Guides on setting output mode, reversed output, set value, and hysteresis for flow, temp, pressure.

Details how to configure ON and OFF delay times for the OUT1 signal.

Covers settings for reversed output and accumulated increment/decrement for accumulated flow.

Guides on setting reversed output and accumulated pulse value for OUT1.

Explains how to configure reversed output for error output mode.

Details how to set the output to OFF mode for OUT1.

Explains how to configure the output mode for OUT2, referencing OUT1 settings.

Details how to set the digital filter to reduce noise in flow rate measurements.

Details how to set the digital filter to reduce noise in pressure measurements.

Allows manual fine-tuning of the displayed pressure value within a specific range.

Enables rotating the display and reversing button functions for installation flexibility.

Sets the display to zero for low flow rate values to improve accuracy.

Sets the display to zero for low pressure values to improve accuracy.

Table showing displayable flow rate ranges based on zero cut-off settings.

Table showing displayable pressure ranges based on zero cut-off settings.

Describes how zero cut-off settings affect operating points and hysteresis.

Allows users to choose which measurements (Pressure, Temp, Accumulated Flow) are displayed.

Enables storing the accumulated flow value in memory periodically to prevent data loss.

Configures the display to automatically turn off after a period of inactivity to save power.

Allows enabling or disabling the security code to prevent unauthorized access.

Provides steps for changing the security code when the device is unlocked.

Allows enabling or disabling all configurable functions simultaneously.

Provides a reference table for the order in which functions can be set.

Enables checking the average cycle time for IO-Link communication.

Allows selecting between normal output and forced output checks for verification.

Guides on checking accumulated pulse output for OUT1 and OUT2.

Details checking the accumulated SW1 bit status for IO-Link communication.

Details checking the accumulated SW2 bit status for IO-Link communication.

Details checking the flow rate SW1 and SW2 bit status for IO-Link.

Details checking the temperature SW1 and SW2 bit status for IO-Link.

Details checking the pressure SW1 bit status for IO-Link.

Details checking the pressure SW2 bit status for IO-Link.

Details checking the flow rate unit and criteria bit status for IO-Link.

Details checking the flow rate diagnosis bit status for IO-Link.

Details checking the temperature diagnosis bit status for IO-Link.

Details checking the pressure diagnosis bit status for IO-Link.

Details checking error and system error bit status for IO-Link.

Details checking the accumulated value status for IO-Link.

Guides on checking flow rate, temperature, and pressure values for IO-Link.

Guides on how to reset all product settings to their original factory defaults.

Describes how to reset accumulated flow, peak, and bottom values.

Allows capturing and storing the current measured value as a set point.

Allows temporary switching of accumulated flow display digits for better readability.

Allows adjusting the pressure display to zero within a specified range.

Details how to lock and unlock the device keys to prevent accidental changes.

Guides on resetting the product after unexpected power interruptions or de-energization.

Provides steps for recovering the security code if it has been forgotten.

Describes communication, status monitoring, and data storage capabilities via IO-Link.

Lists key communication parameters for IO-Link, including version and speed.

Details the bit offset mapping for various process data items exchanged with the master.

Explains the Big-Endian and Little-Endian data formats for transmission methods.

Specifies the rated and settable ranges for flow, temperature, and pressure measurements.

Lists the ranges for Process Data (PD) values corresponding to measurements.

Provides formulas for converting between process data and measured values.

Describes the IODD file and its purpose for establishing IO-Link communication.

Lists direct parameters like Vendor ID and Device ID accessible via IO-Link.

Provides an overview of ISDU parameters, including system commands and device lock.

Details system commands for device control and the device access lock function.

Describes the meanings of different device states like Normal Operation, Failure, etc.

Lists detailed event contents, classifications, and error codes for device status monitoring.

Details configurable parameters for OUT1, including flow, temperature, and pressure settings.

Details configurable parameters for OUT2, including flow, temperature, and pressure settings.

Details settings for accumulated flow, pulse output, and related parameters for OUT1/OUT2.

Details settings for delay times, and error/off modes for OUT1/OUT2.

Covers communication test, conversion equation parameters, and measurement-related settings.

Explains parameter data types, storage, and the toggle output command.

Maps specific values to setting contents and supplemental information displayed on the sub screen.

Details sub screen data mapping for OUT1/OUT2 and IO-Link mode display.

Provides a table for diagnosing and resolving common operational issues like output problems.

Lists error indications and their corresponding countermeasures for system errors and over-current.

Addresses troubleshooting for display issues such as flashing, accuracy, and button malfunctions.

Provides solutions for common IO-Link communication problems like indicator errors and data swapping.

Explains error codes for exceeding flow, pressure, or temperature ranges and their resolutions.

Details error codes for over current, system errors, accumulated flow, and version mismatches.

Lists specifications related to flow rate, pressure ranges, and increments.

Details specifications for switch outputs, load current, voltage, and display characteristics.

Lists specifications for digital filter, environmental resistance, standards, and piping.

Lists communication parameters and cable specifications for IO-Link mode.

Presents pressure loss graphs as a function of flow rate under different supply pressures.

Shows the temperature accuracy relative to the flow rate.

Provides detailed dimensional drawings and measurements for the product models.

Details the specifications and pinouts for the M12 connector lead wires.