5-2

DNW-A75/A75P

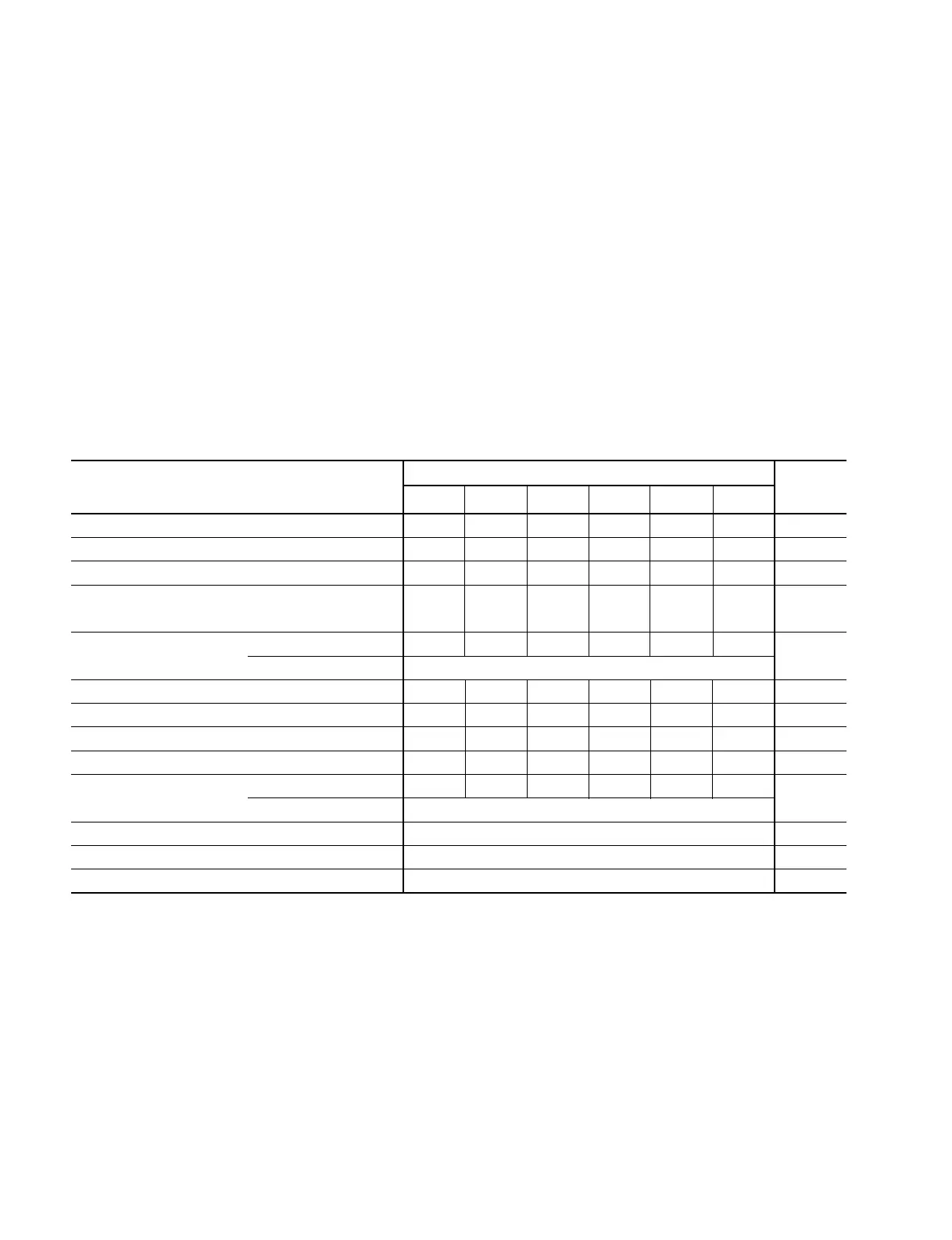

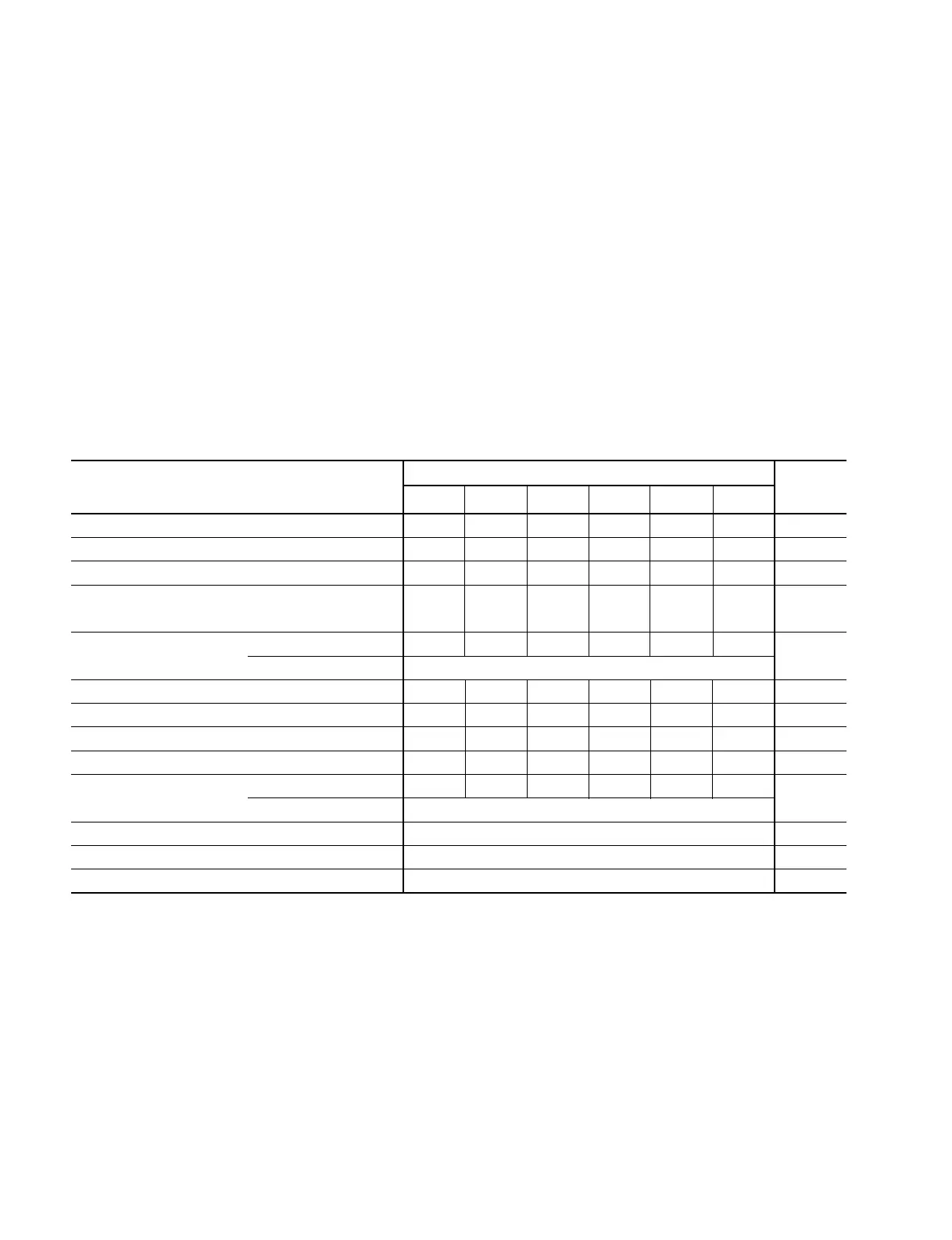

5-1-2. Periodic Replacement and Check Item Table

The replacement time shown in the following table is not the guarantee term of

parts. The replacement time of parts varies depending on the operating environment

and conditions of the unit.

Especially the pinch roller and cleaners, may be required replacing earlier than

replacement period shown in the table depending on the degree of their dirt or

abrasion.

The arrows “↓” and “↑” in the table indicate that the part is included in the assembly

described on the lower/upper line. If the assembly on the pointed line is replaced, the

part is also replaced as a component of the assembly together.

As for the hours meter, refer to Section 5-1-3.

As for replacing each part, refer to the maintenance manual Part 2, Volume-1.

R : Replace the part. C : Perform check (adjustment).

Replace it depending on its condition.

Hours meter

Inspection hours (h)

No. Replacement parts (Menu No.) 1000 2000 3000 4000 5000 6000

1 Upper drum Drum rotating time (H02) C

*1

C

*1

C

*1

C

*1

C

*1

(↓)

2 Drum assembly

*2

Drum rotating time (H02) C

*3

3 Brush slip ring assembly Drum rotating time (H02) R (↑)

4 Video head cleaner Drum rotating time (H02) C

*4

C

*4

C

*4

C

*4

C

*4

↓

5 Video head Drum rotating time (H02) R

cleaner assembly

*5 *6

Threading times (H04) Replace when used 200,000 times

6 AT head cleaner Drum rotating time (H02) C

*4

RC

*4

RC

*4

R

7 Pinch roller Tape running time (H03) C

*4

RC

*4

RC

*4

R

8 Reel motor Tape running time (H03) R

9 Capstan motor Tape running time (H03) R

!/ Pinch solenoid

*6

Tape running time (H03) R

Threading times (H04) Replace when used 200,000 times

!- Fan motor (rear) Energized time (H01) Replace when used 40,000 hours

!= Fan motor (MD) Energized time (H15) Replace when used 40,000 hours

Loading...

Loading...