Oxygen Analyzer

4–18 4900002239 rev. G 7-11-17

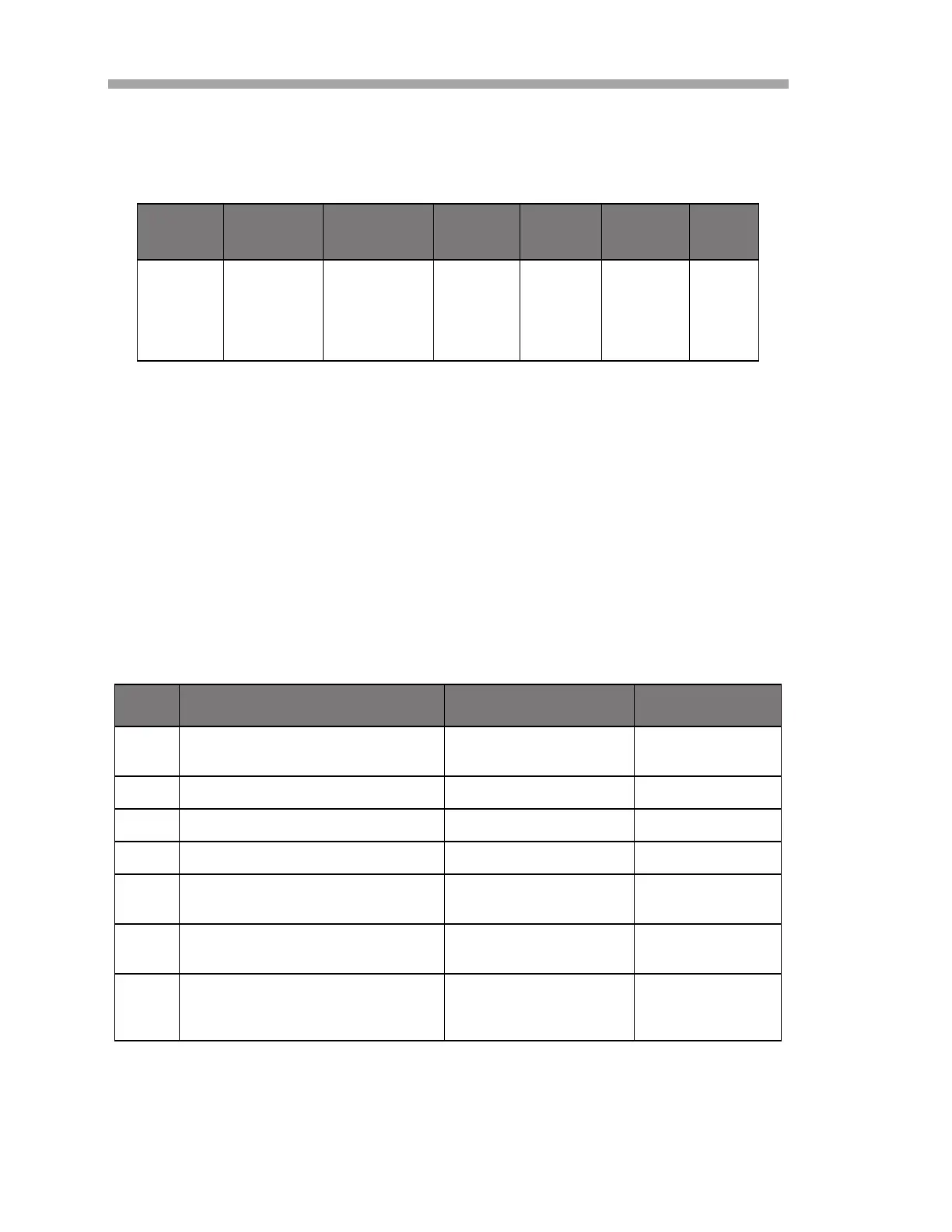

Ethernet Subnet Mask

Examples

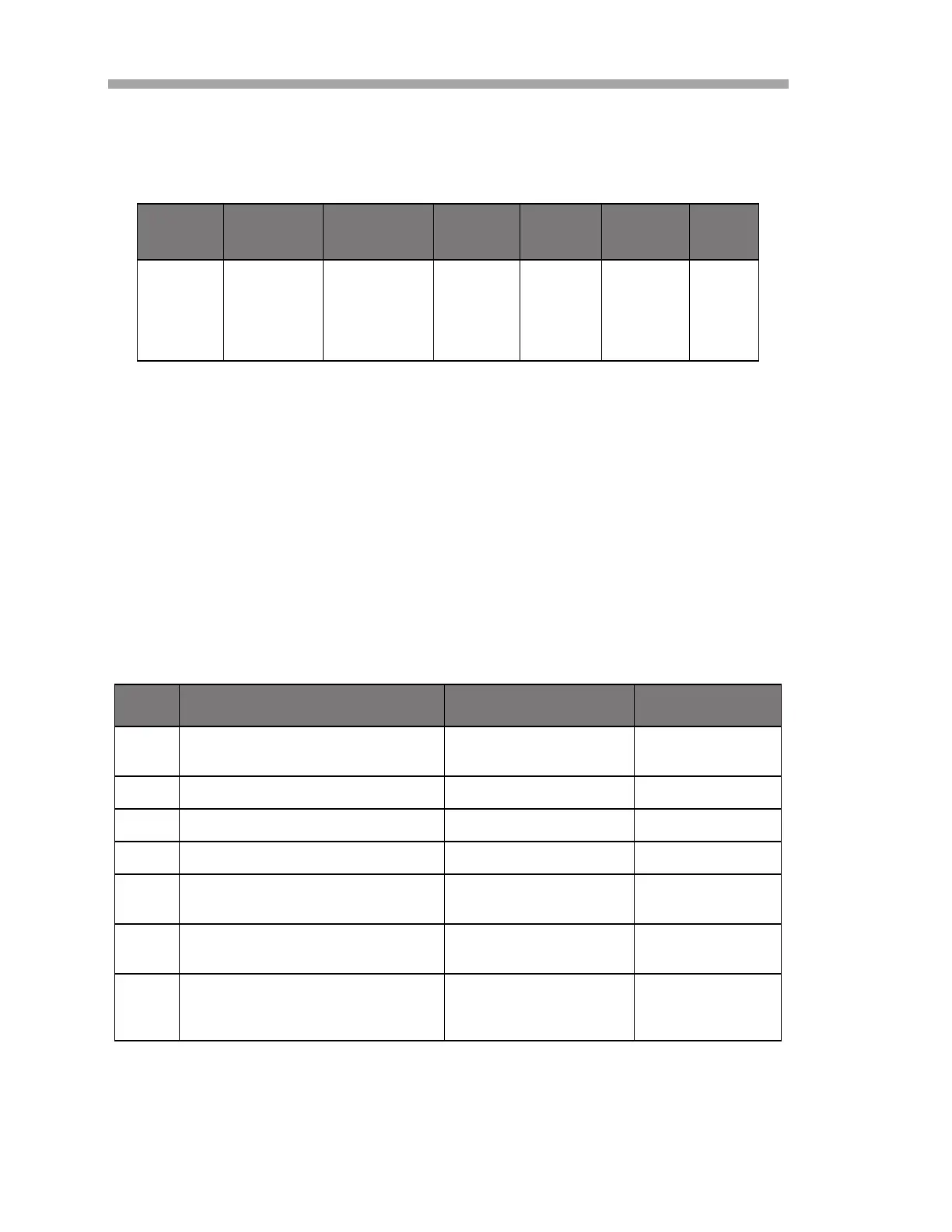

Configuration of a Continuous Measurement

Precondition: Sensor is connected, sensor constants and calibration values

are already set up correctly (OP-9).

The goal for this configuration is a continuous measurement with a 1 minute

interval, pressure sensor and RTD (Pt100) are deactivated. Instead a manual

fixed value will be transmitted. Refer to Table 4–17.

Table 4–16 Definition of register 5685

Start

Register

Number of

Registers

Reg1/

Reg2

Reg3/

Reg4

Reg5/

Reg6

Reg7/

Reg8

Write

Access

5685 8 Int32:

Ethernet

Subnet Mask

Octet 1

Int32:

Ethernet

Subnet

Mask

Octet 2

Int32:

Ethernet

Subnet

Mask

Octet 3

Int32:

Ethernet

Subnet

Mask

Octet 4

Yes

Table 4–17 Configuration for a continuous measurement

Step Description Register(s) Value

1 Stop the measurement, in case it is

running.

5707, 5708 0 (Int32)

2 Set pressure mode to ‘Manual’. 5705 0 (Boolean)

3 Set manual pressure to “1006.23”. 3147, 3148 1006.23 (Float)

4 Set temperature mode to “Manual”. 5611 0 (Boolean)

5 Set manual temperature to

“20.56”.

2409, 2410 20.56 (Float)

6 Set the interval rate to 1 min.

(60s).

3499, 3500 60 (Int32)

7 Activate the interval mode and

start the continuous measurement

immediately.

5707, 5708 5 (Int32 trans-

lates to 00000101

binary)

Loading...

Loading...