182

Internal Gearshift Mechanism

Inspection

Refer to

figure

81

for this procedure.

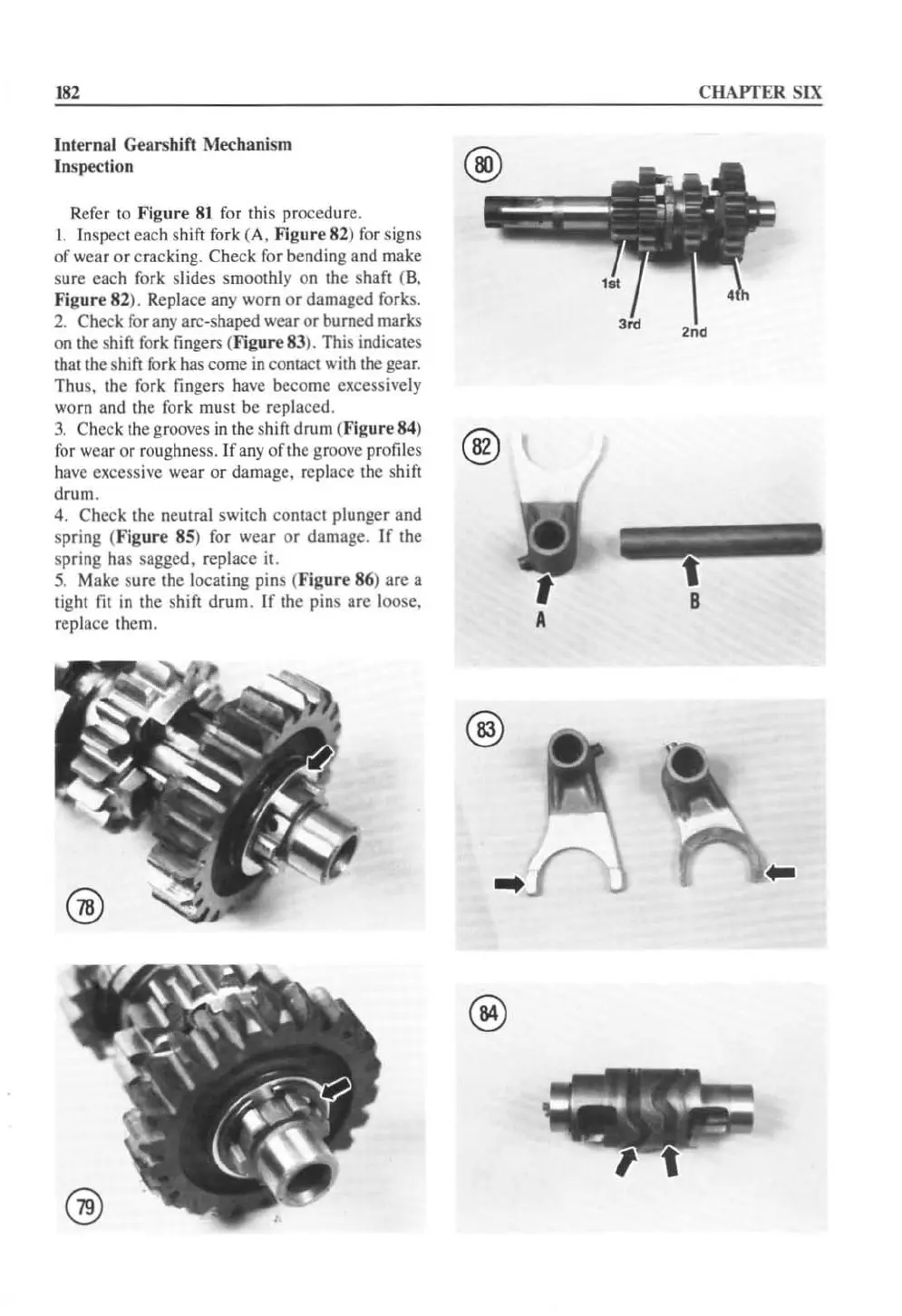

1.

In

spect each shift fork (A.

Figure

82) for signs

of

w

ea

r

or

c

ra

ckin

g.

Check for bending and make

sure each fork slides smoothly on the shaft (B.

Figure

82). Replace any worn

or

damaged forks.

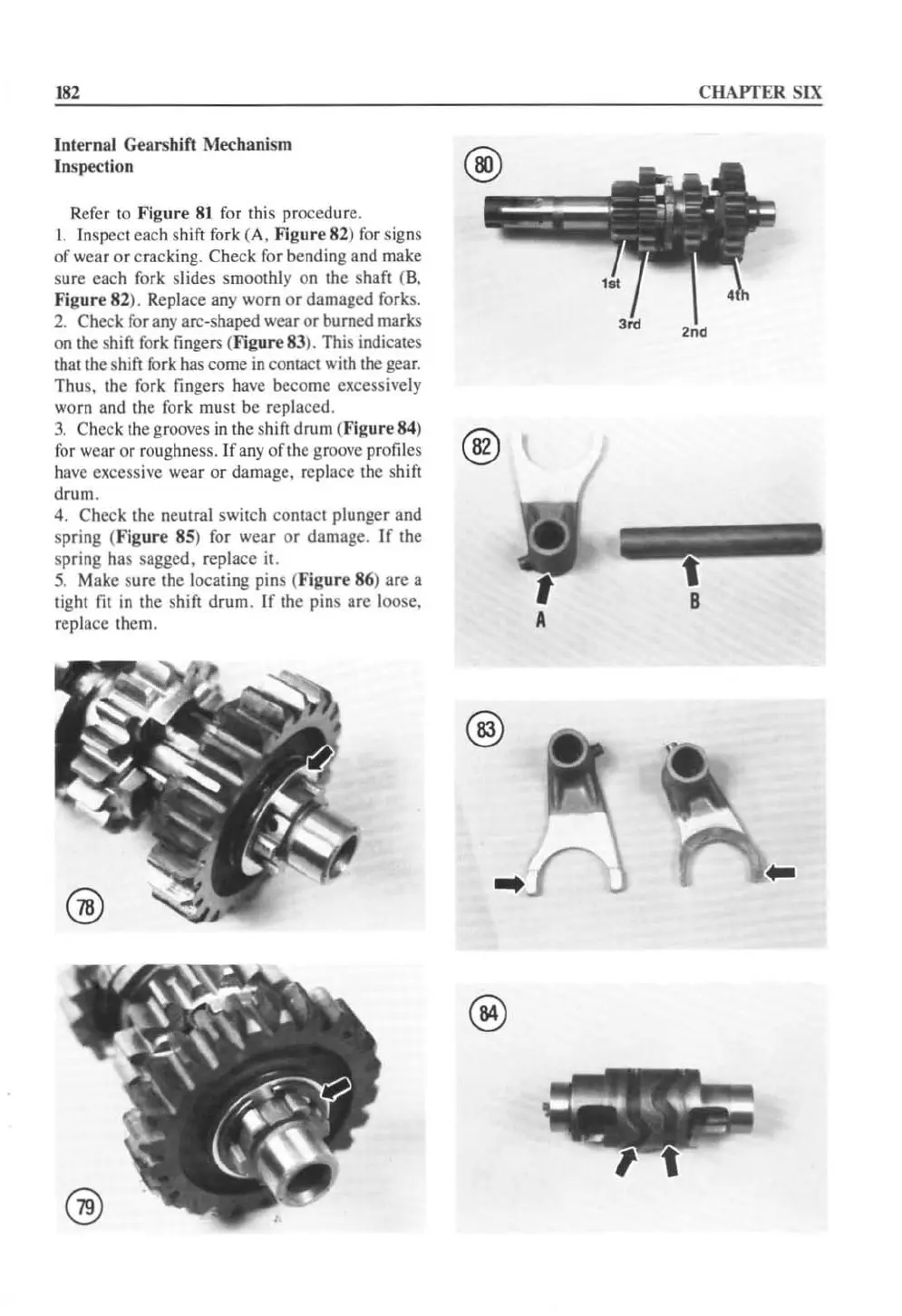

2. Check for any arc·shaped wear

or

burned marks

on

th

e shift fork fingers (

Figure

83). This indicates

that

th

e shift fork has come in contact with

th

e gear.

Thu

s.

the fo

rk

fin

ge

rs ha

ve

become excessively

worn and the fork

mu

st be replaced.

3.

Check

th

e grooves

in

the shifl drum (Figure 84) ®

for

wear

or r

oug

hne

ss.

Iran

y

or

lh

c gr

oove

profiles

82

have excessive wear or damage. re

pl

ace the shift

drum

.

4. Check the neutral switch contact plunger and

spring (

Figure

85)

fo

r wear or damage. If Ihe

spring has sagge

d,

replace

il

.

5.

Make sure

Ih

e localing pins (I'

igure

86) are a

lighl til in Ihe shifl drum.

If

Ih

e pins are loose,

replace

Ih

em.

®

CHAPTER S

IX

t

B

A

Loading...

Loading...