54

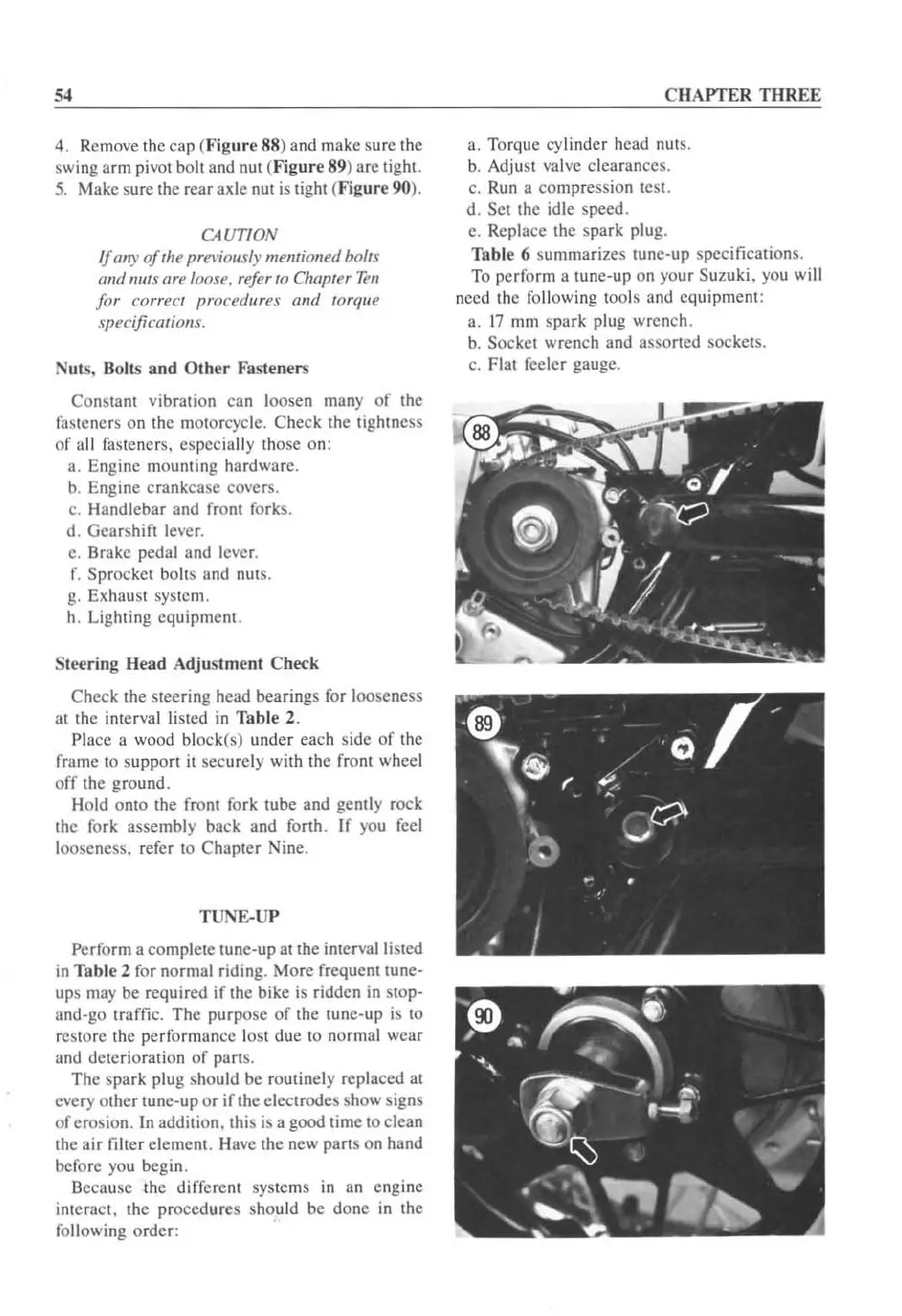

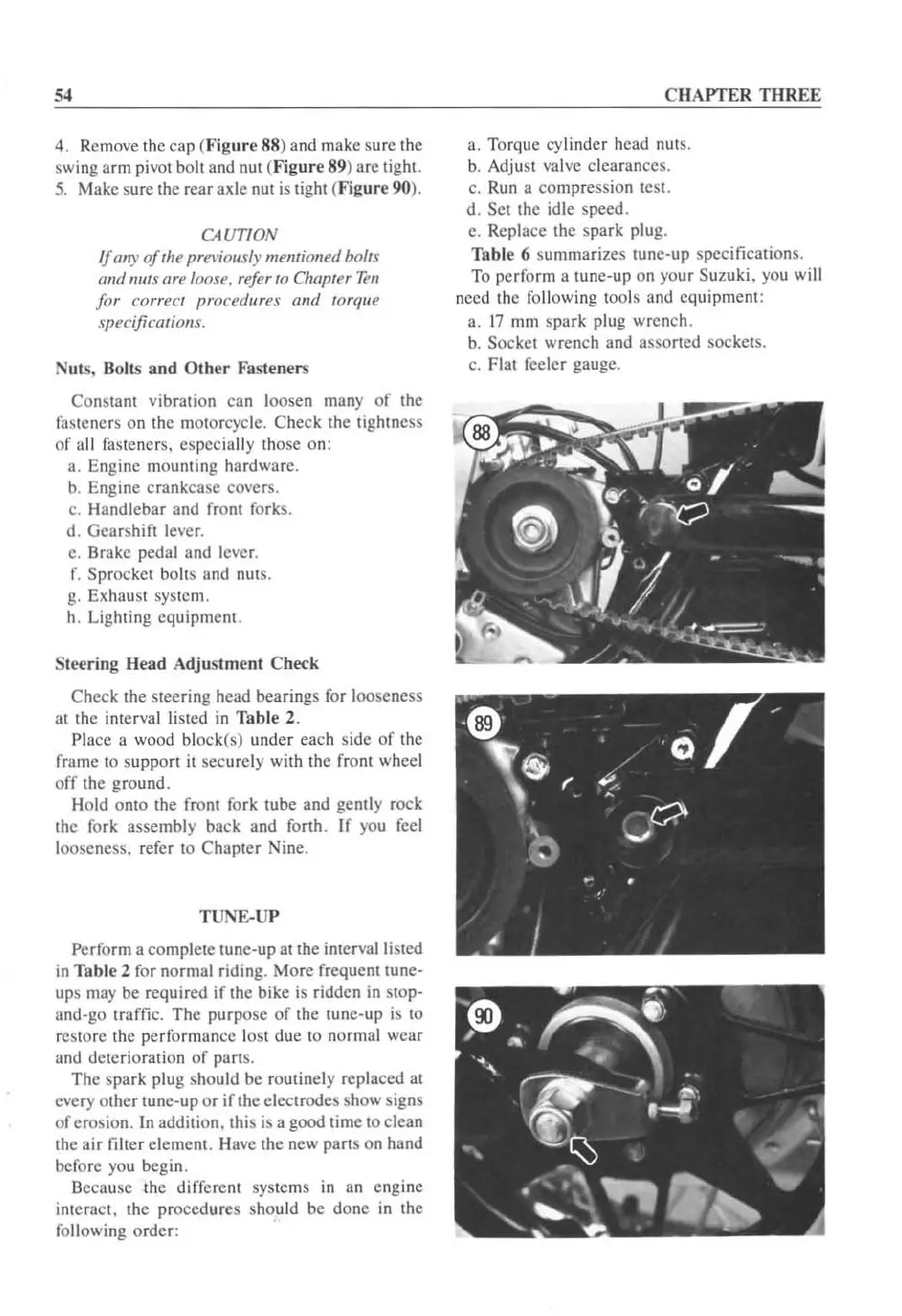

4. Remove the cap (Figure 88) and make

S

Ufe

the

swing arm pivot bolt and

nUl

(F

igure

89

) arc ligh!.

5.

Make sure the

fc

ar

ax

le nut is tight

(F

igure 90).

CAUTION

If

wry

of

the

pre\'iously

mentioned

boils

amI

nuts are

foose,

refer

to

Chapter

Tell

for correct procedures and torque

specificatiolls.

Nuts, Bolts and

Other

.'astencrs

Constant vibration cnn loosen many

of

the

fasteners on the motorcycle. Check the tightness

of

all fasteners. especia

ll

y those on:

a. Engine mounting hardware.

b. Engine crankcase covers.

c. Handlebar and front forks.

d. Gearshift lever.

c.

Brake pedal and lever.

f. Sprocket bolls and nut

s.

g.

Exhaust system .

h. Lighting equipment.

Steer

in

g Head Adjustment Check

Check the steering head bearings for looseness

at the inter

val

listed in Table 2.

Place a wood block(s)

un

der each side

of

the

frame

to

support

it

securely with the front wheel

off the ground.

Hold

OniO

the front fork tube and gently rock

the fork assembly back and forth. If

you

feel

looseness. refer

to

Chapter Nine.

TUNE-UP

Pcrform a complete tunc-up

at

the interval listed

in Table 2 for normal riding. More frequent

tune-

ups

may

be

required if the bike is ridd

en

in

stop-

and-go

traffic. The

pu

rpose

of

the tune-up is

to

restore the performance lost due to nor

mal

wear

and deterioration

of

parts.

The spark p

lu

g should be routinely rcplaced at

every other tunc-up

or

if the electrodes show signs

of

erosion. In addition. this

is

a good ti

me

to

clean

the air filte r clement. Have the new

pans

on hand

before

you

begin.

Because the differe

nt

sys

tems

in

an engine

interact. the procedures should

be

done

in

the

following order:

CHAPTER THREE

a. Torque cylinder head nuts.

b.

Adjust valve clearances.

c.

Run

a comp

re

ssion test.

d. Set the idle speed.

e.

Replace the spark plug.

Table

6 summarizes tunc-up specifications.

To

perform a

tu

ne-up

on

your Suzuki.

you

will

need

th

e

foll

owing tools and

eq

uipment:

a.

17

mm spa

rk

p

lu

g wrench.

b.

Socket wrench and assorted soc

kct

s.

c.

Flat

fee

l

er

gauge.

Loading...

Loading...