LUBRICATION, MAINTENANCE

AND

TVNE·UP

Exhaust System

Cheek

for

leakage

at

a

ll

fittings. Tighten

all

bolts

and

nut

s.

Replace any gaskets if necessary. Refer

to

Exhaust Syslem

in

Chapter Seven.

Wheel Bearings

There

is

no factory-recommended mileage

inter

va

l

for

cleaning and repacking the wheel

bearings. They sho

uld

be inspected and serviced.

if necessar

y.

eve

ry time the wheel is removed

or

whenever there is a likelihood

of

water

contaminatio

n.

The correct service procedures are

covered

in

Chapter Nine and Chapter Ten.

Front Suspension Check

I. Apply the front brake and pump the forks

up

and down

as

vigorously

as

possible. Check

for

smooth operation and check

for

any oil leaks.

2.

Make sure the lower

for

k bridge bolt

is

tight

(Figure

81

)

on

each side.

3.

Make sure the fork top cap bolt (Figure 82)

is

tight on each fork leg.

4.

Remov

e the tr

im

caps (Figure

83

) and make

sure the

bollS

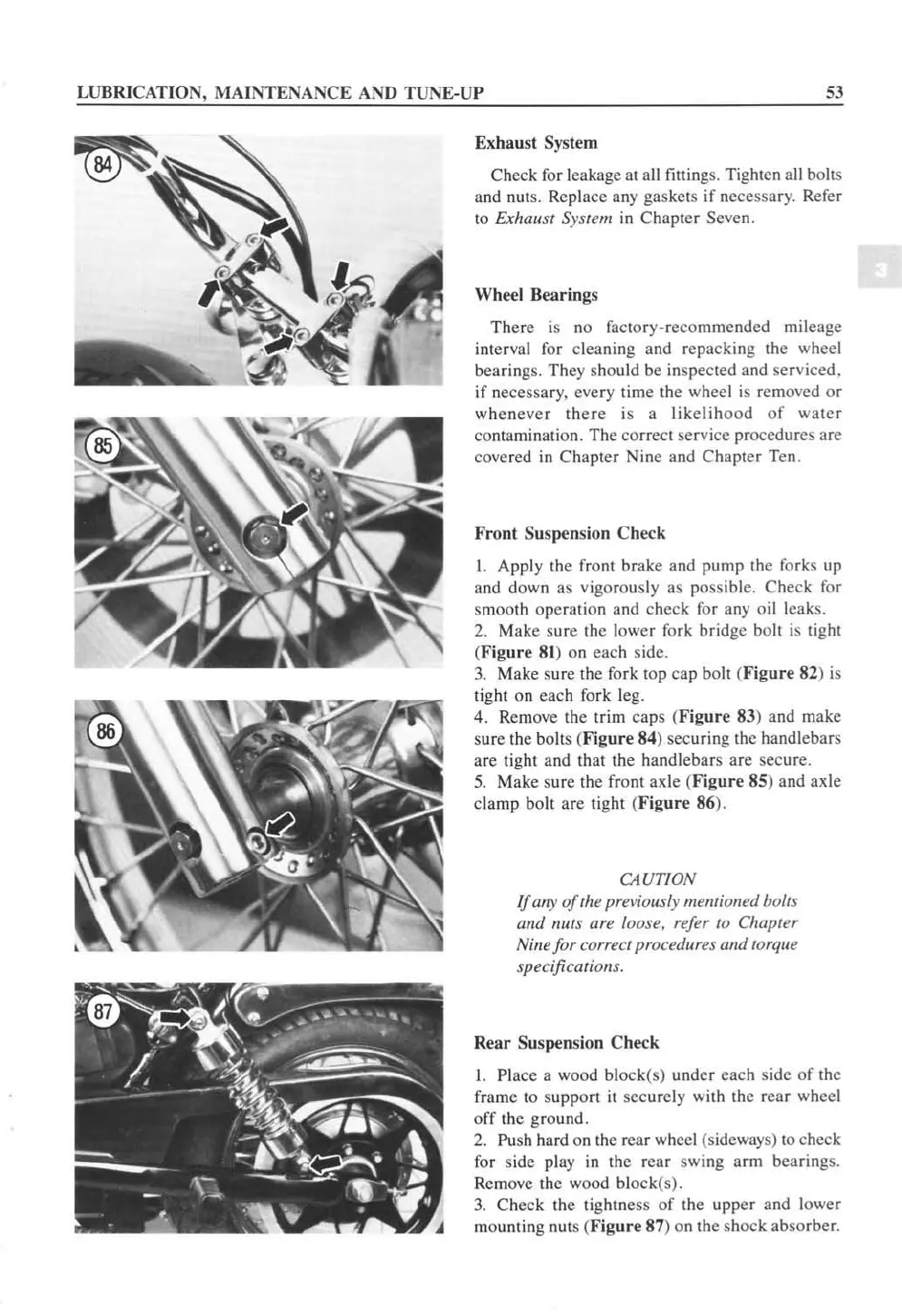

(Figure 84) securing the handlebars

are tight and that the handlebars are secure.

5.

Make sure the front axle (Figure 85) and

ax

le

clamp bolt are tight (Figure 86).

CAUTION

If

wr)'

of

the previously memiolled bollS

alld

IIul

S lire loose. refer to Chapter

Nine for correct procedures (/lid torque

specijicaliolls.

Re

ar Suspension Ch

ec

k

I. Place a wood block(s) under each side

of

the

frame

to

support it securely with the rear wheel

off the ground.

2.

Pu

sh hard on the rear wheel (sideways)

to

check

for

side pl

ay

in

the rear swing arm bearings.

Remove the wood block(s).

3.

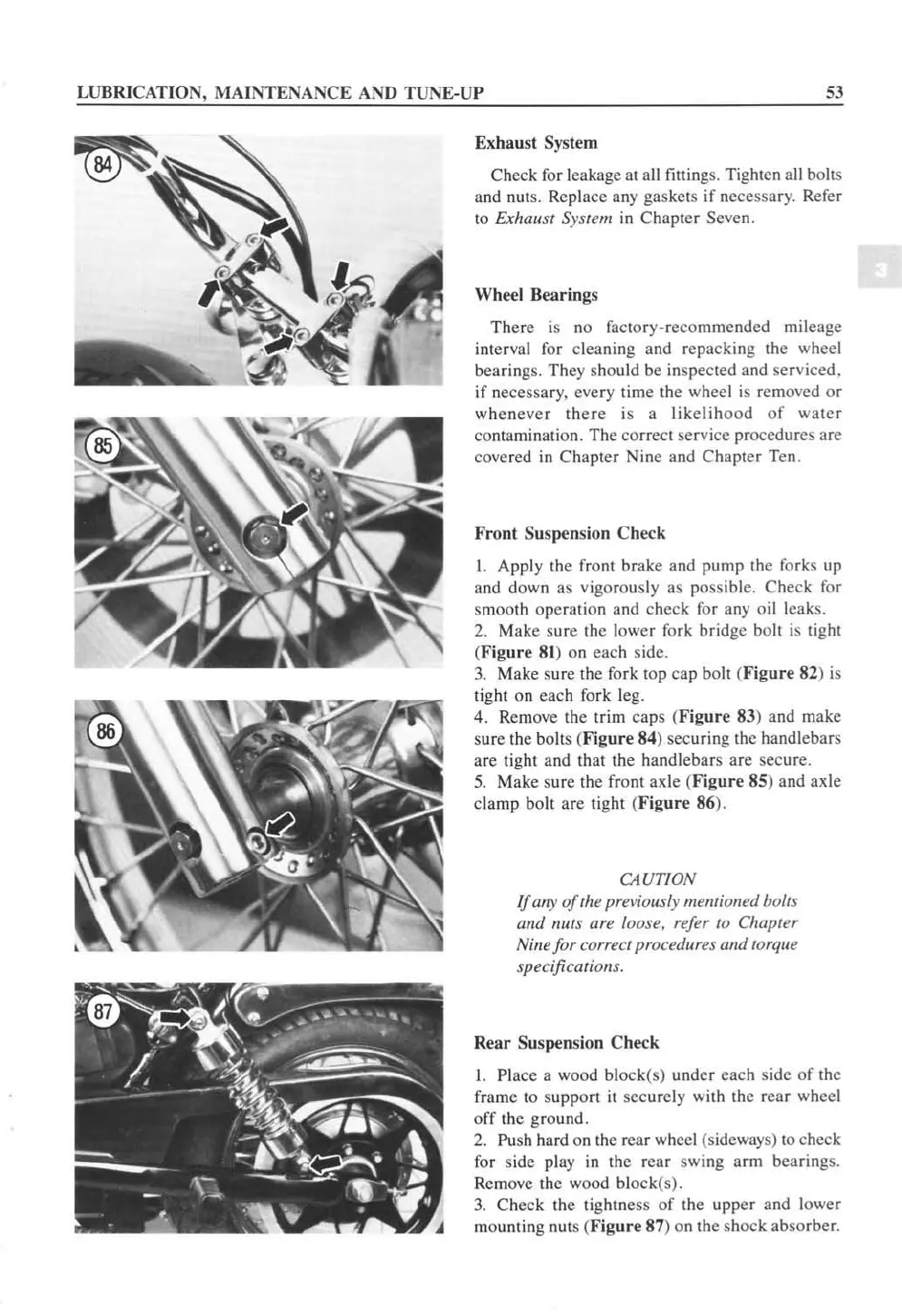

Check the tightness

of

th

e upper and lower

mo

unt

ing

nuts (Figure 87) on the shock absorber.

Loading...

Loading...