1730–Series Maintenance

6–3

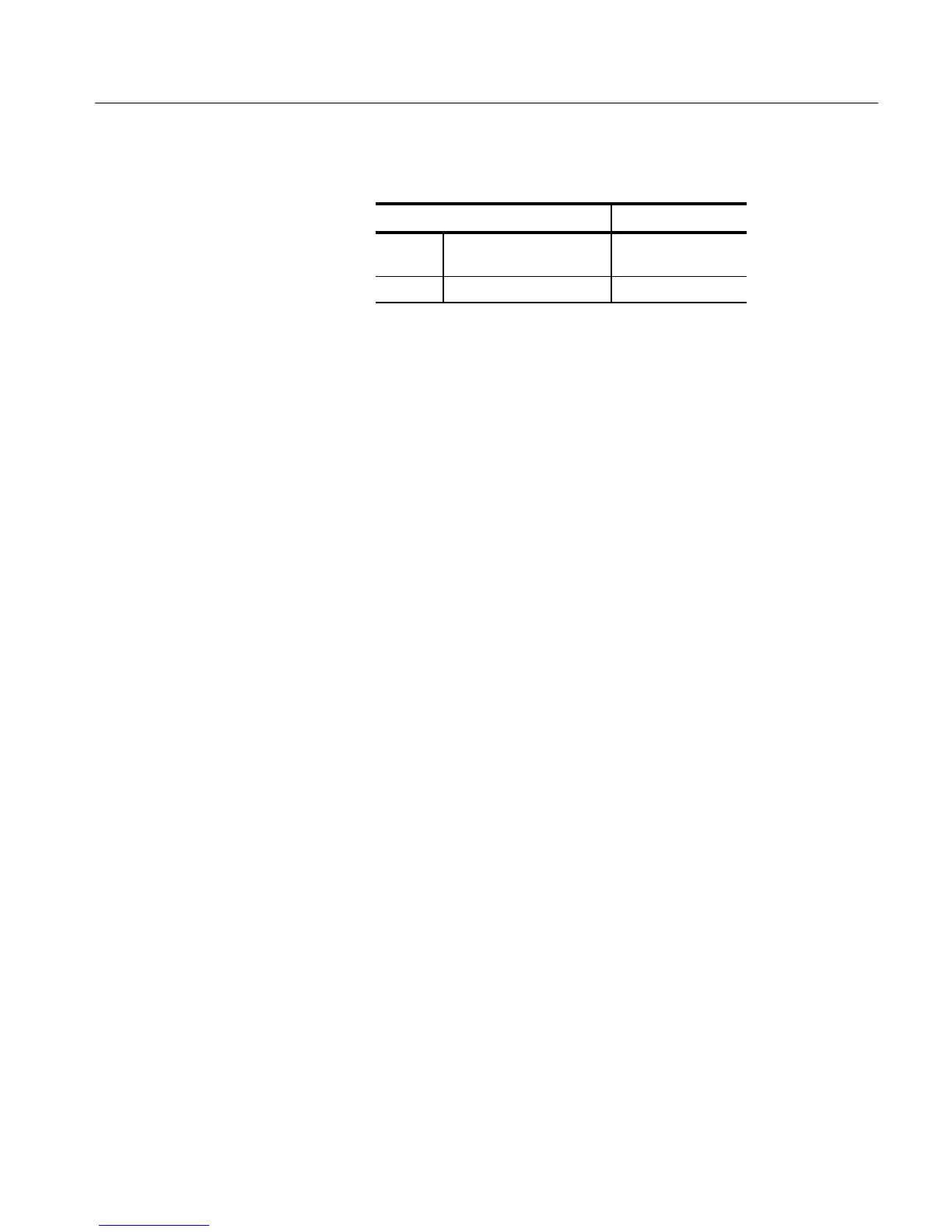

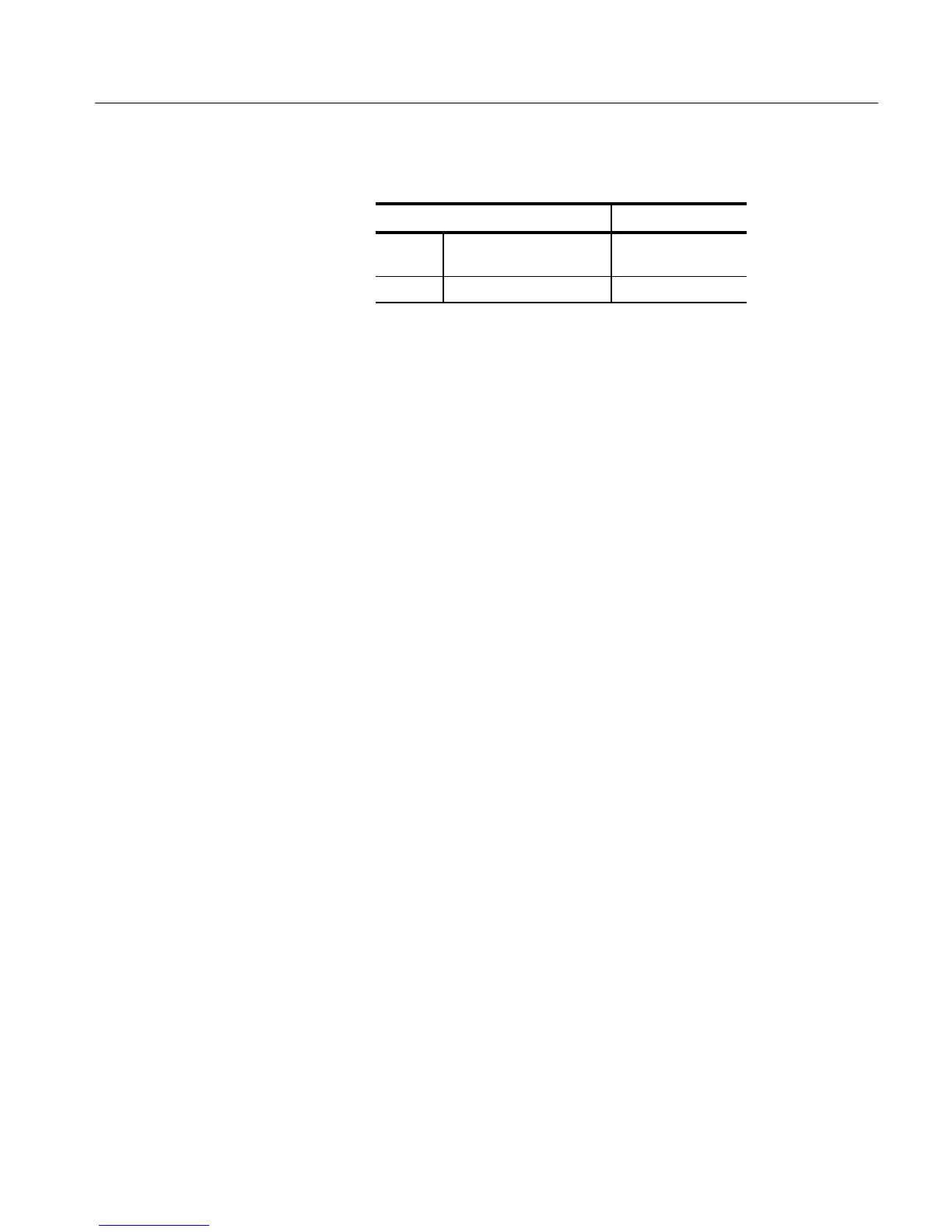

Table 6–1: (Cont.)Static Susceptibility

Relative Susceptibility Levels Voltage

LOW POWER SCHOTT-

KY TTL

TTL

Observe the following precautions to avoid damage:

1. Minimize handling of static–sensitive components.

2. Transport and store static–sensitive components or assemblies in their

original containers, on a metal rail, or on conductive foam. Label any

package that contains static–sensitive components or assemblies.

3. Discharge the static voltage from your body, by wearing a wrist

grounding strap, while handling these components. Servicing static–sensi-

tive assemblies or components should be done only at a static–free work

station by qualified personnel.

4. Nothing capable of generating or holding a static charge should be

allowed on the work station surface.

5. Keep the component leads shorted together whenever possible.

6. Pick up the components by the body, never by the leads.

7. Do not slide the components over any surface.

8. Avoid handling components in areas that have a floor or work surface

covering capable of generating a static charge.

9. Use a soldering iron that is connected to earth ground.

10. Use only special antistatic, suction, or wick–type desoldering tools.

Instrument performance should be checked after each 2000 hours of operation, or

every 12 months, if used intermittently. This will help to ensure maximum

performance and assist in locating defects that may not be apparent during

regular operation. The Performance Check Procedure and the Adjustment

Procedure are in Section 5.

Troubleshooting

The material contained here is general and is not intended to cover specific cases.

Performance Checks and

Readjustments

Loading...

Loading...