1730–Series Maintenance

6–14

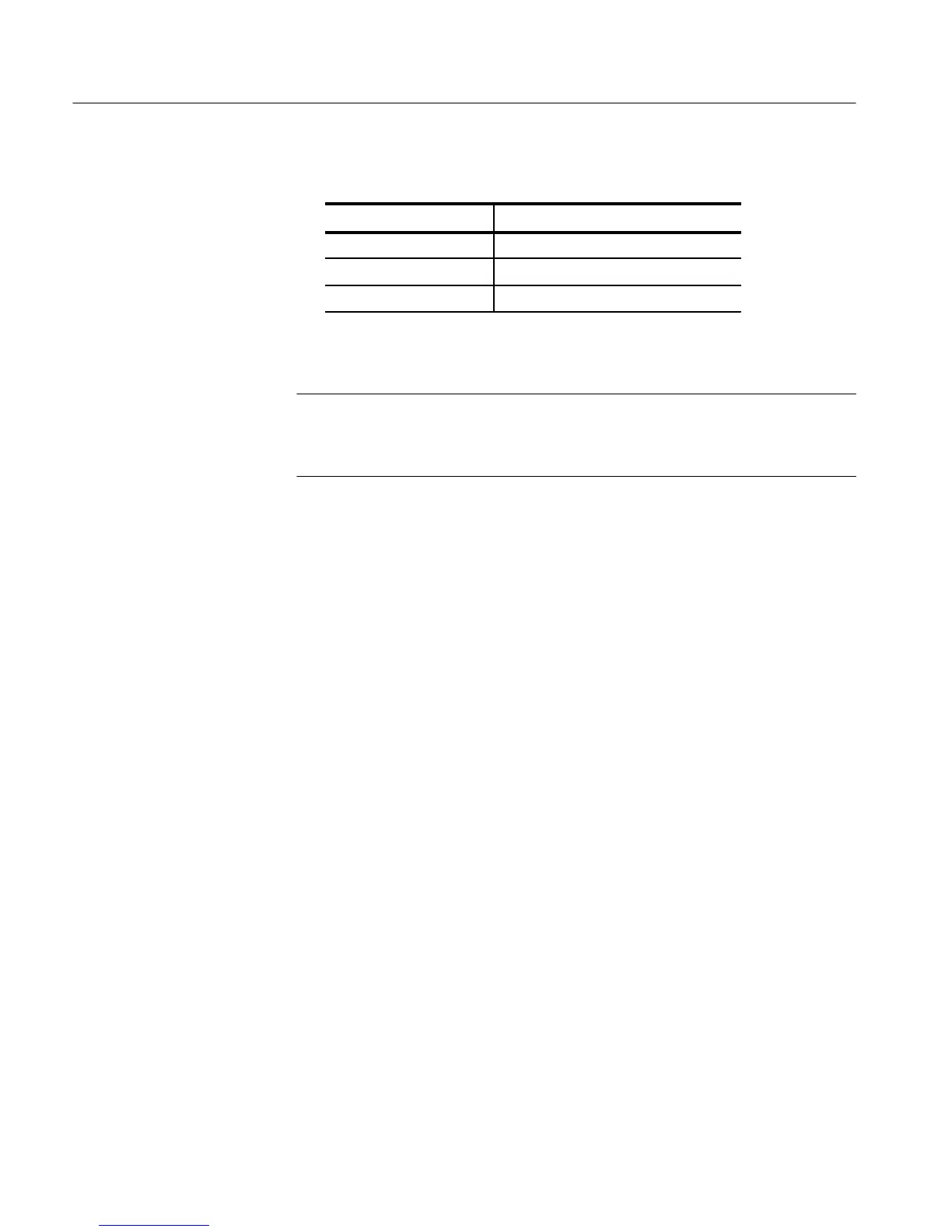

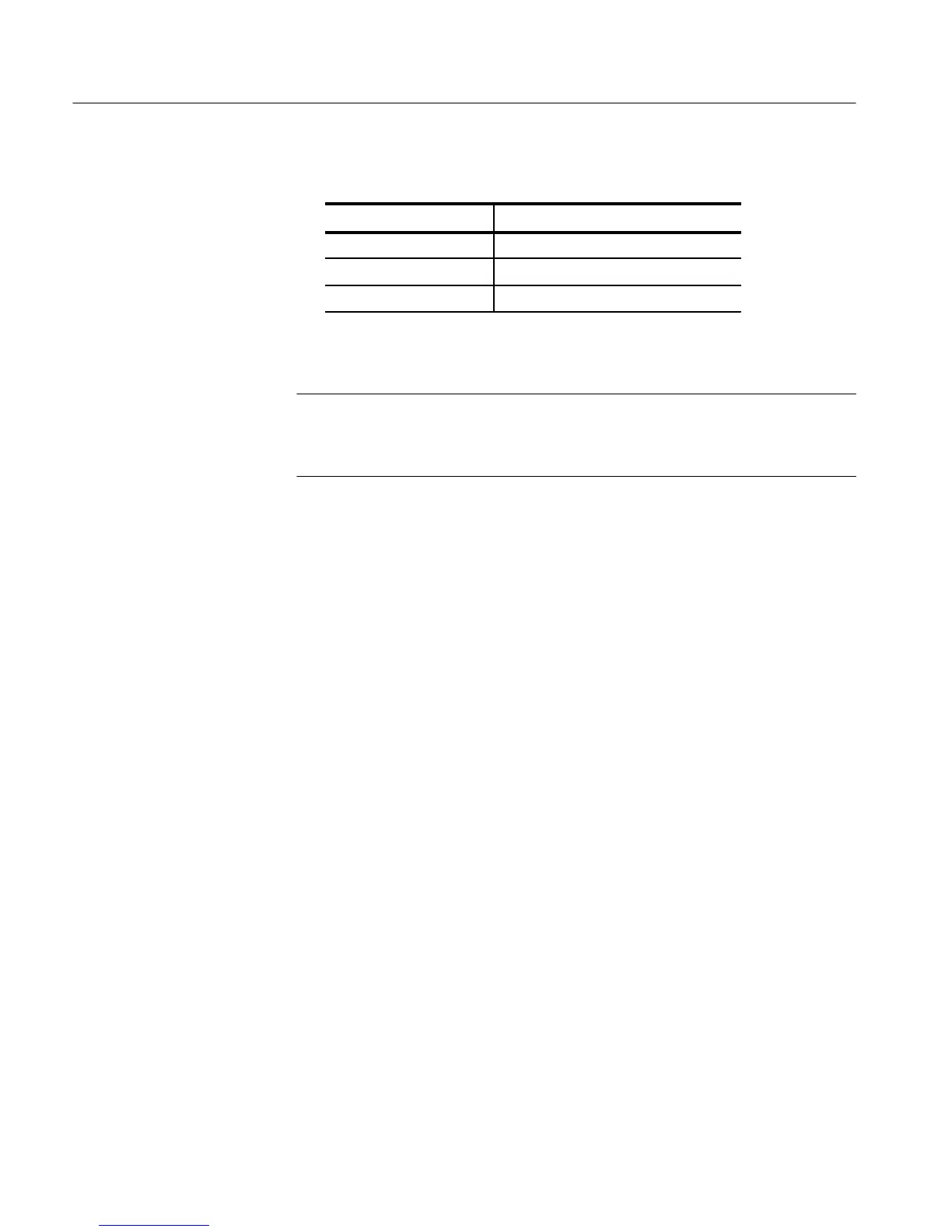

Table 6–6: (Cont.)High Voltage Oscillator Test Points

Circuit Location Voltage

U2, pin 2 Approximately +4.8 V

U2, pin 6 +4 to +11 V

CR9, cathode Approximately +100 V

6. CRT Voltage Check

NOTE. High Voltage Probe:

This check requires a high voltage probe having an input resistance of 1 GW or

more.

a. Connect the high voltage probe ground to TP1.

b. Load the Low Volts supply with the instrument, or with a 20W, 2 watt

resistor loading the 5 V supply.

c. Power up the power supply.

d. Use the high voltage probe to measure the voltage at the anode of CR4.

It should be approximately –2350 V.

e. Measure the voltage at the anode end of CR3. It should be 50–150 V

more negative than the reading from the anode of CR4.

A non–destructive diagnostic program is built into the 1730–Series. All that is

required to perform these diagnostics is a male, 9–pin, sub–miniature D–type

connector with pins 8 and 9 connected together. The procedure contained here

will isolate non–operating front–panel indicators and open or shorted receive and

transmit lines in the serial interface.

1. Turn off instrument POWER.

2. Install the male, sub–miniature D–type connector on the rear–panel

AUXILIARY connector.

3. Hold in the LINE SELECT and POWER switches until all front–panel

indicators light. This step checks:

a. LEDs and LED Drivers

b. Interface continuity (RXD in and TXD out)

When all indicators are lit there is continuity from the Microprocessor, out

through the TXD Buffer, and back through the RXD Buffer. If all front–pan-

Serial Port and LED Driver

Diagnostics

Loading...

Loading...