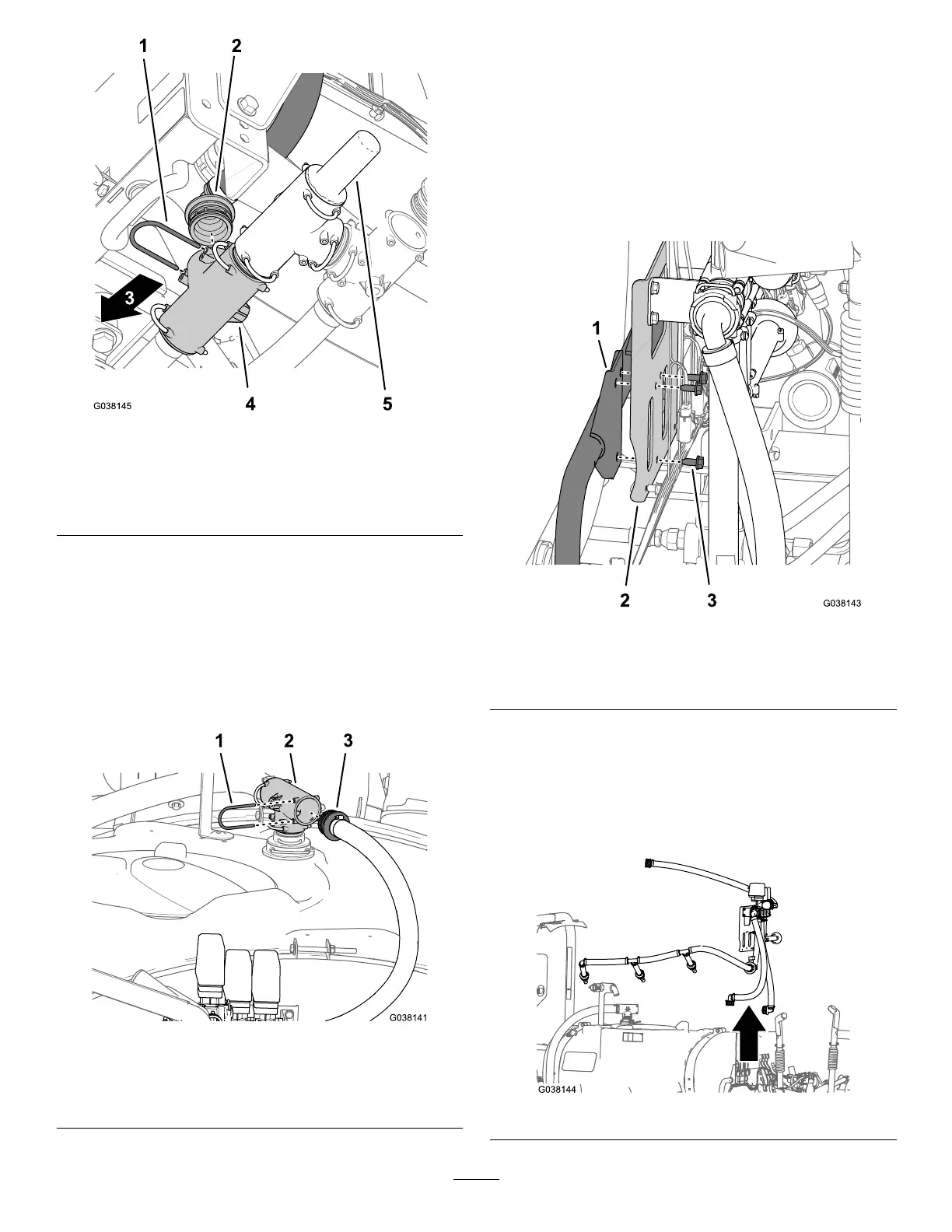

Figure24

1.Retainer

4.T-tting

2.90°barbedtting(sprayer

supplyhose)

5.Pressure-reliefvalve

3.Frontofthemachine

4.Removethe90°barbedttingfromtheT-tting

(Figure24).

5.Atthetopoftheofthesprayertank,removethe

retainerthatsecuresthestraightbarbedttingofthe

bypasshosetotheT-tting(Figure25).

Note:RetaintheretainersforinstallationinInstalling

theBypassHose—MachineswithouttheOptional

SprayWandKitorElectricHoseReelKit(page33).

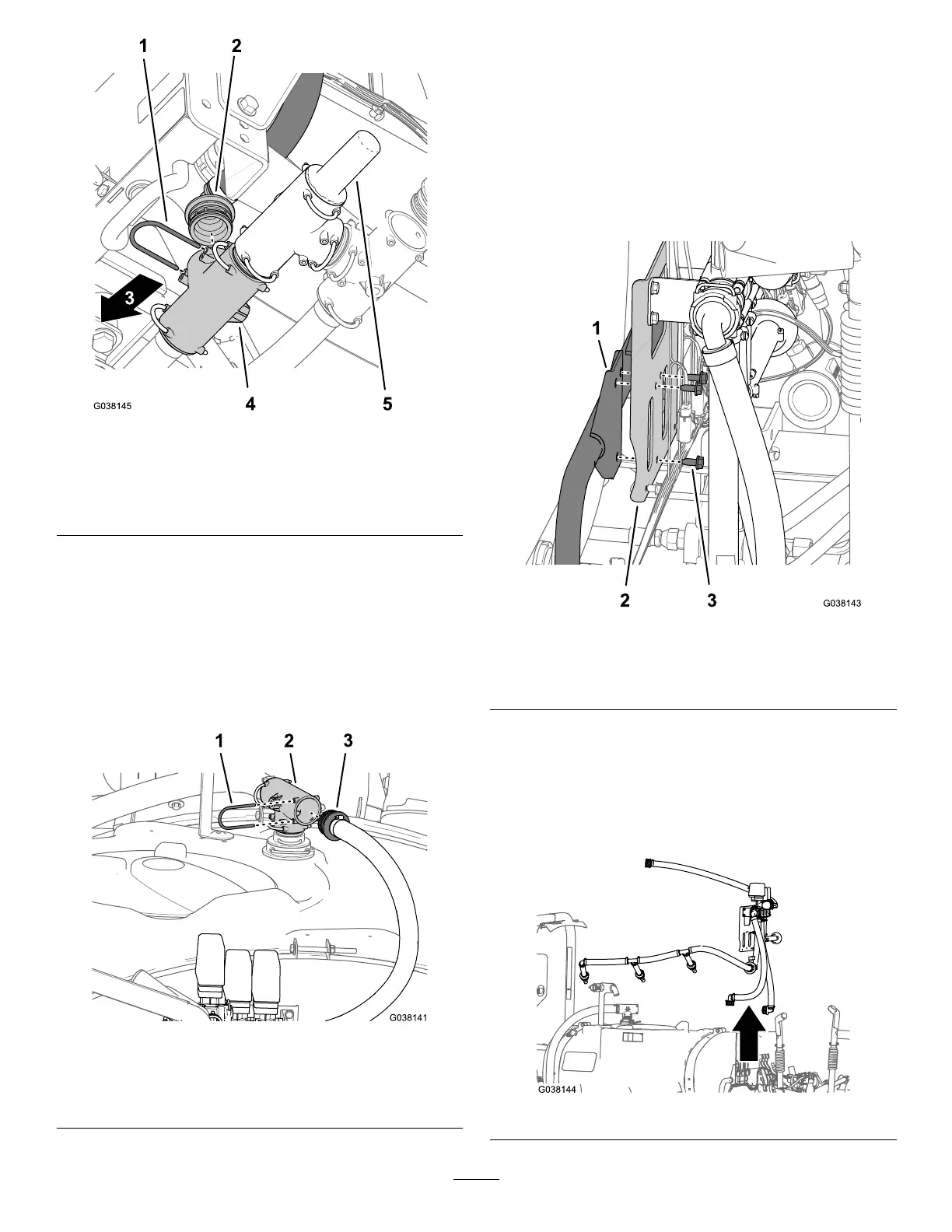

Figure25

1.Retainer

3.Straightbarbedtting

(bypasshose)

2.T-tting

6.RemovethestraightbarbedttingfromtheT-tting

(Figure25).

RemovingtheAgitation,Rate,and

Master-SprayValvesfromtheMachine

1.Whilesupportingthebracketfortheagitation,rate,

andmaster-sprayvalves,removethe3ange-head

bolts(5/16x3/4inch)thatsecurevalvebrackettothe

mount(Figure26).

Figure26

1.Mount

3.Flange-headbolts(5/16x

3/4inch)

2.Bracket

2.Removethebracket,valves,hoses,andagitation

nozzlesfromthemachine(Figure27).

Note:Retainthe3ange-headbolts(5/16x3/4inch)

forinstallationinInstallingtheAgitation,Rate,and

Master-SprayValveManifold(page24);younolonger

needthebracket,valves,hoses,andagitationnozzles.

Figure27

15

Loading...

Loading...