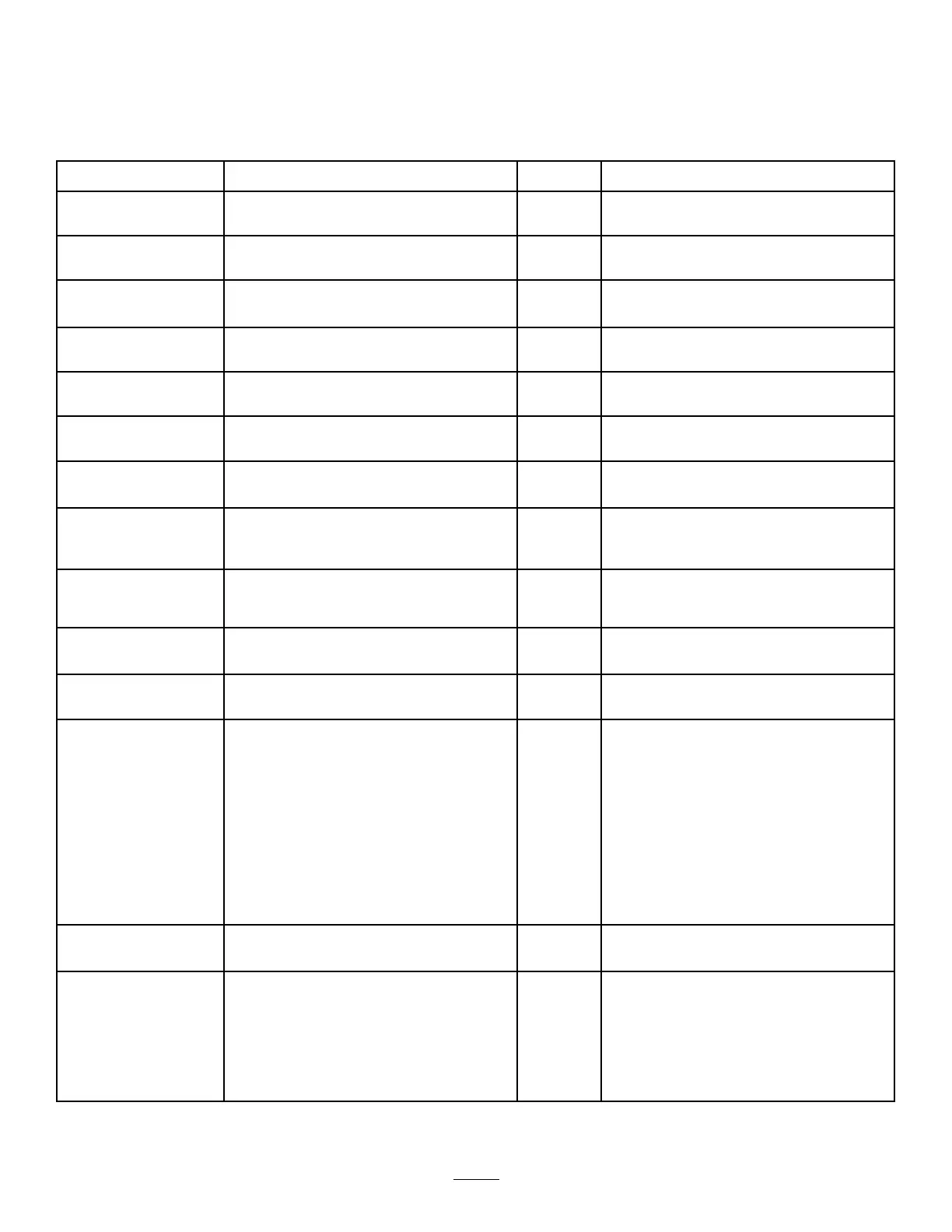

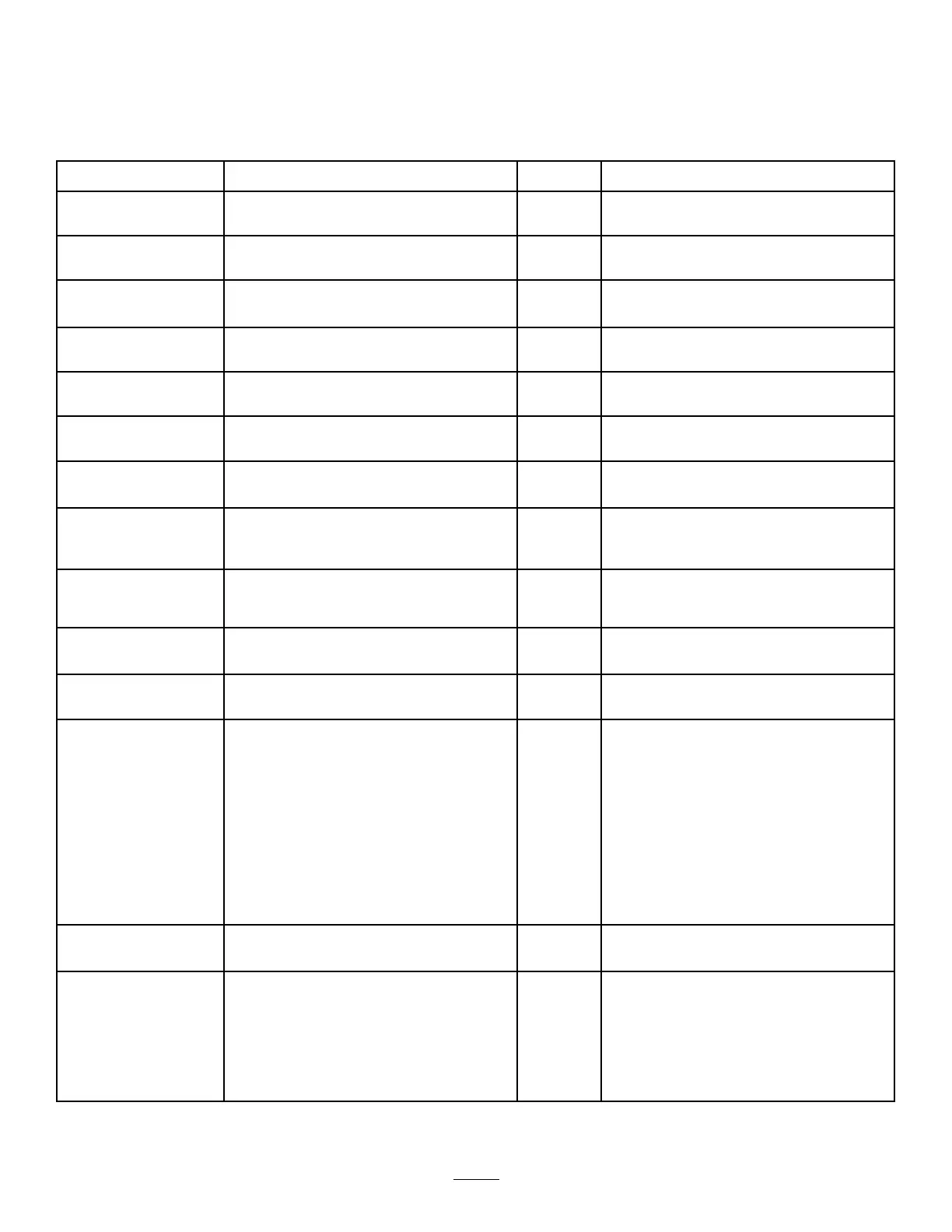

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

1

Nopartsrequired

–

Preparetoinstallthekit.

2

Nopartsrequired

–

Disconnectingthepressure-sensetube.

3

Nopartsrequired

–

Disconnectthewireharnessfromthe

valves.

4

Nopartsrequired

–

Disconnecttheoptionalattachments.

5

Nopartsrequired

–

Removetheboom-sectionvalves.

6

Nopartsrequired

–

Removetheagitationnozzles.

7

Nopartsrequired

–

Removetheagitation,rate,and

master-sprayvalves.

Cableties

6

3-pinadapter

5

8

4-pinadapter1

Replacethevalveelectricalconnectors.

Agitation,rate,andmaster-spray

manifold

1

9

Sectionvalvemanifold

1

Installthevalveassemblies.

10

Flow-meterhose—25x289mm(1x

11-3/8inches)

1

Installtheowmeterandhoses.

11

Nopartsrequired

–

Connectthewireharness.

Handle1

Screw(6-32x5/8inch)

1

Agitationthrottlevalve1

Bracket(nylon)

1

Agitation-valvebracket1

Bolt(6x12mm)

4

Eductor-shutoffvalve

1

Eductor-shutoffbracket

1

Flangelocknut(1/4inch)

4

12

Flange-headbolt(5/16x3/4inch)

2

Installingtheagitationthrottlevalveand

eductor–shutoffvalveformachineswith

theoptionaleductorkit.

13

Agitation-nozzleassembly1

Installingtheagitation-nozzleassembly

andhoses.

Returnhose—2.5x72cm(1x27-7/8

inches)

1

Agitationsupplyhose—2.5x72cm(1x

28-1/4inches)

1

14

Bypasshose—2.5x110cm(1x43-1/2

inches)—machineswithouttheoptional

spraywandorelectrichosereelkit

1

Installthereturnhose,agitationsupply

hose,andbypasshose.

3

Loading...

Loading...