Multi Pro 1750

Page 5 − 44

Electrical System

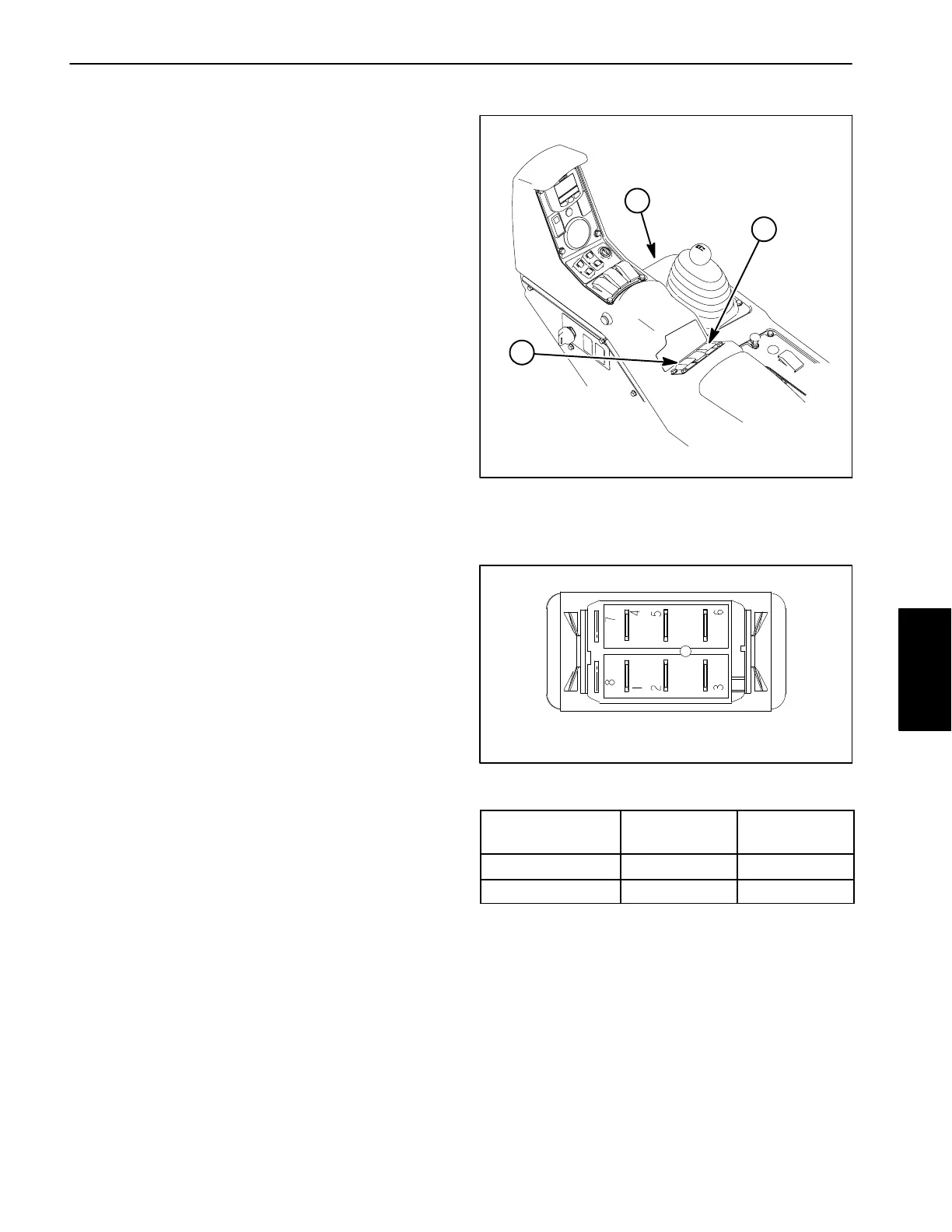

Spray Pump and Agitation Switches

The spray pump and agitation switches are identical

switches and are located on the control console

(Fig. 50). These switches include an indicator light to

notify the operator when the switches are in the ON posi-

tion.

The spray pump switch allows the operator to energize

or de−energize the spray pump electric clutch. The Toro

Electronic Controller (TEC) monitors the operation of

the spray pump switch as an input and provides an out-

put to energize the pump electric clutch when appropri-

ate.

NOTE: To avoid damaging the spray pump drive, the

spray pump switch will only engage when the engine is

at low idle and either the master boom (spray enable)

switch is disengaged or the master boom switch is en-

gaged but none of the boom spray switches are en-

gaged.

The agitation switch allows the operator to energize or

de−energize the spray system agitation valve for spray

tank agitation. On machines with a serial number below

315000000, the switch reverses the polarity of the volt-

age supplied to the agitation valve actuator (2 wire). On

machines with a serial number above 315000000, the

switch removes or applies voltage to the activator termi-

nal (C) to control the agitation valve actuator operation.

Testing

The spray pump switch and its circuit wiring can be

tested as a TEC input or qualifier using the InfoCenter

Display (see InfoCenter Display − Diagnostics Screen in

this chapter). If testing determines that the switch and

circuit wiring are not functioning correctly, proceed with

the following test procedure:

1. Park machine on a level surface, stop spray pump,

stop engine and engage parking brake. Remove key

from ignition switch.

2. Remove console panel. Locate switch that is to be

tested and unplug machine wire harness connector

from switch.

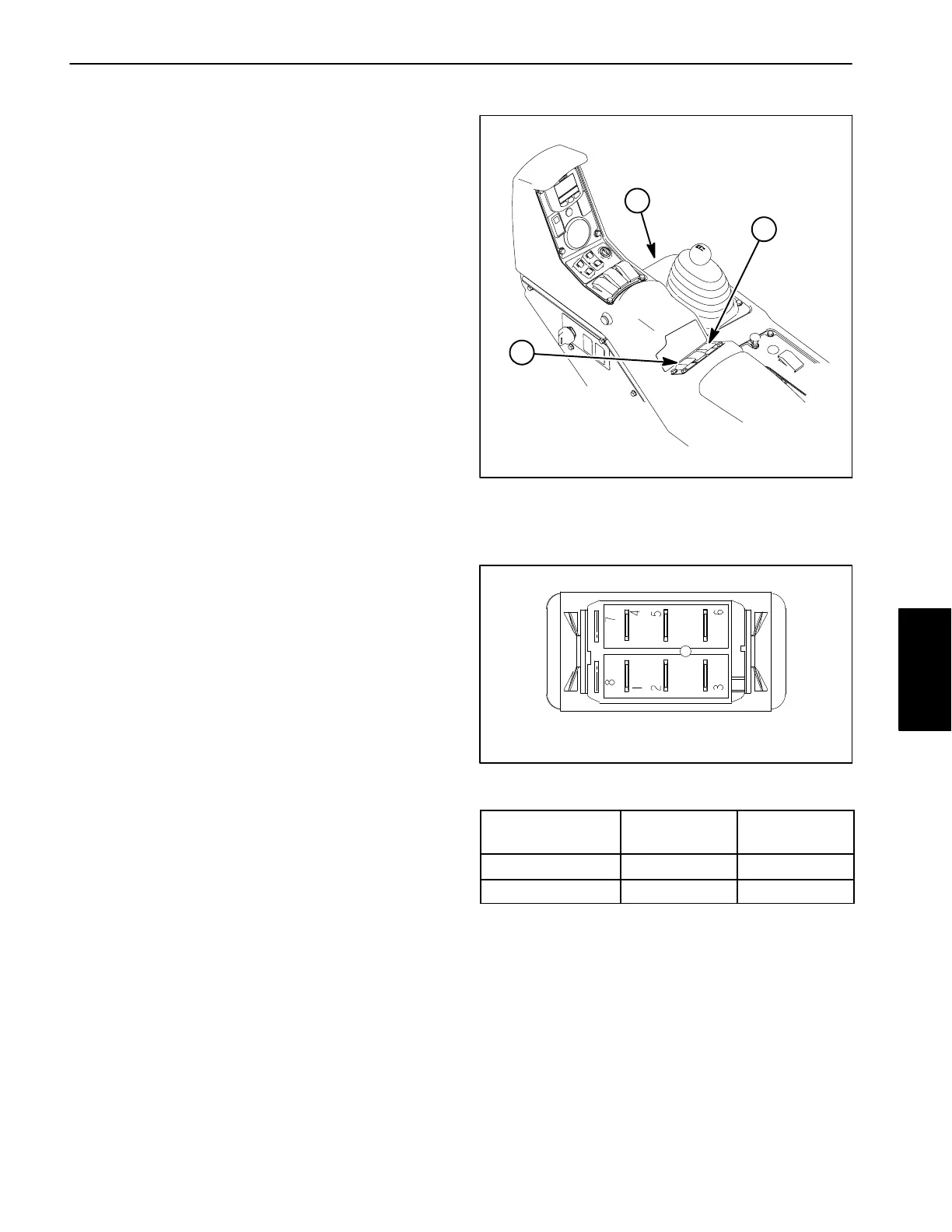

3. With the use of a multimeter (ohms setting), the

switch functions may be tested to determine whether

continuity exists between the various terminals for each

switch position. The switch terminals are marked as

shown (Fig. 51) and the circuitry of the switch is shown

in the chart (Fig. 52). Verify continuity between switch

terminals.

4. Replace switch if testing determines that it is faulty.

1. Control console

2. Pump switch

3. Agitation switch

Figure 50

1

2

3

Figure 51

BACK OF SWITCH

SWITCH

POSITION

NORMAL

CIRCUITS

OTHER

CIRCUITS

OFF 2 + 1 5 + 4

ON 2 + 3 5 + 6

Figure 52

5. Switch terminals 7 (−) and 8 (+) are used for the indi-

cator light in the switch.

6. If the switch tests correctly and a circuit problem still

exists, check wire harness (see Electrical Schematic

and Wire Harness Drawings in Chapter 10 − Electrical

Drawings in this manual).

7. After testing is completed, connect the harness con-

nector to the switch. Install console panel to machine.

Electrical

System

Loading...

Loading...