Multi Pro 1750Page 7 − 4Drive Train

Troubleshooting

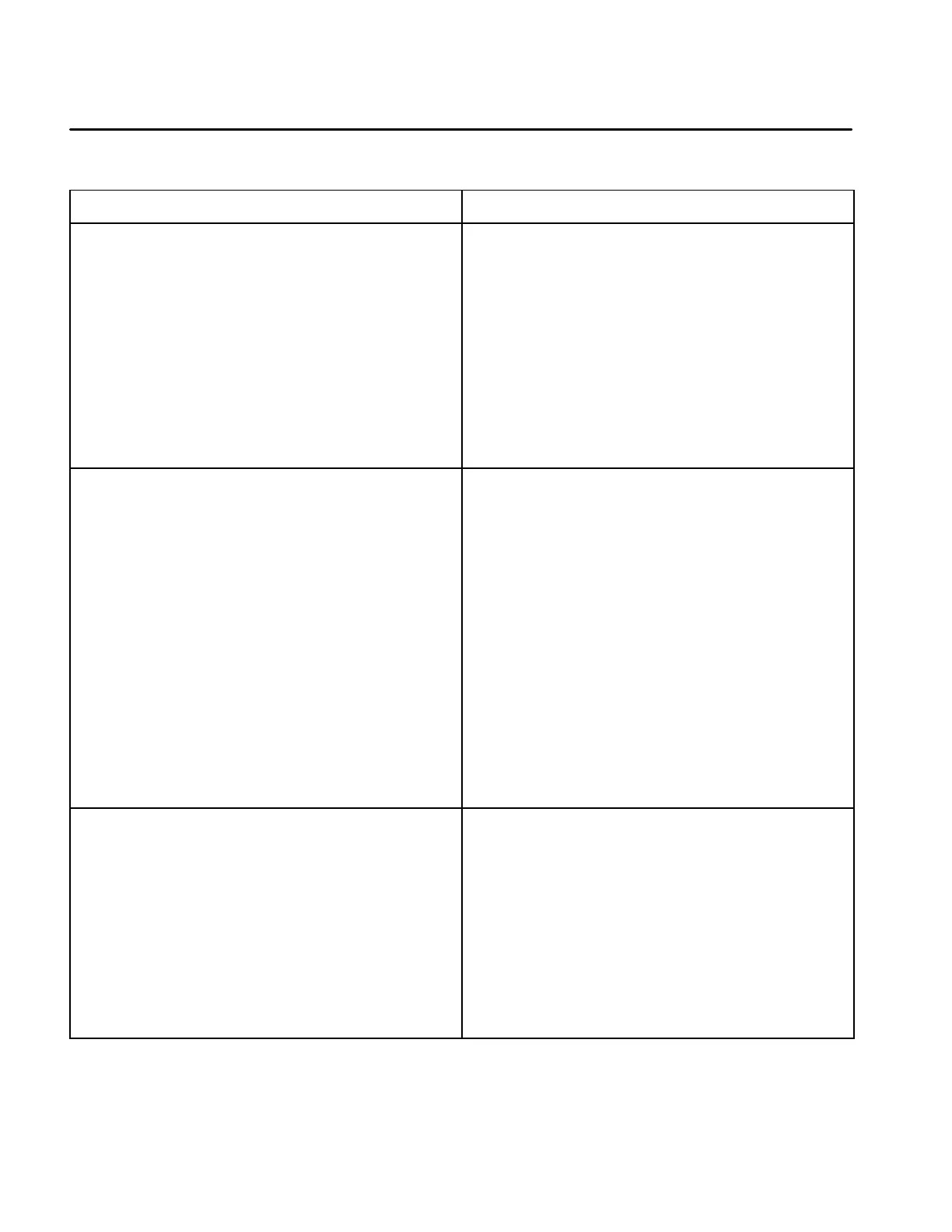

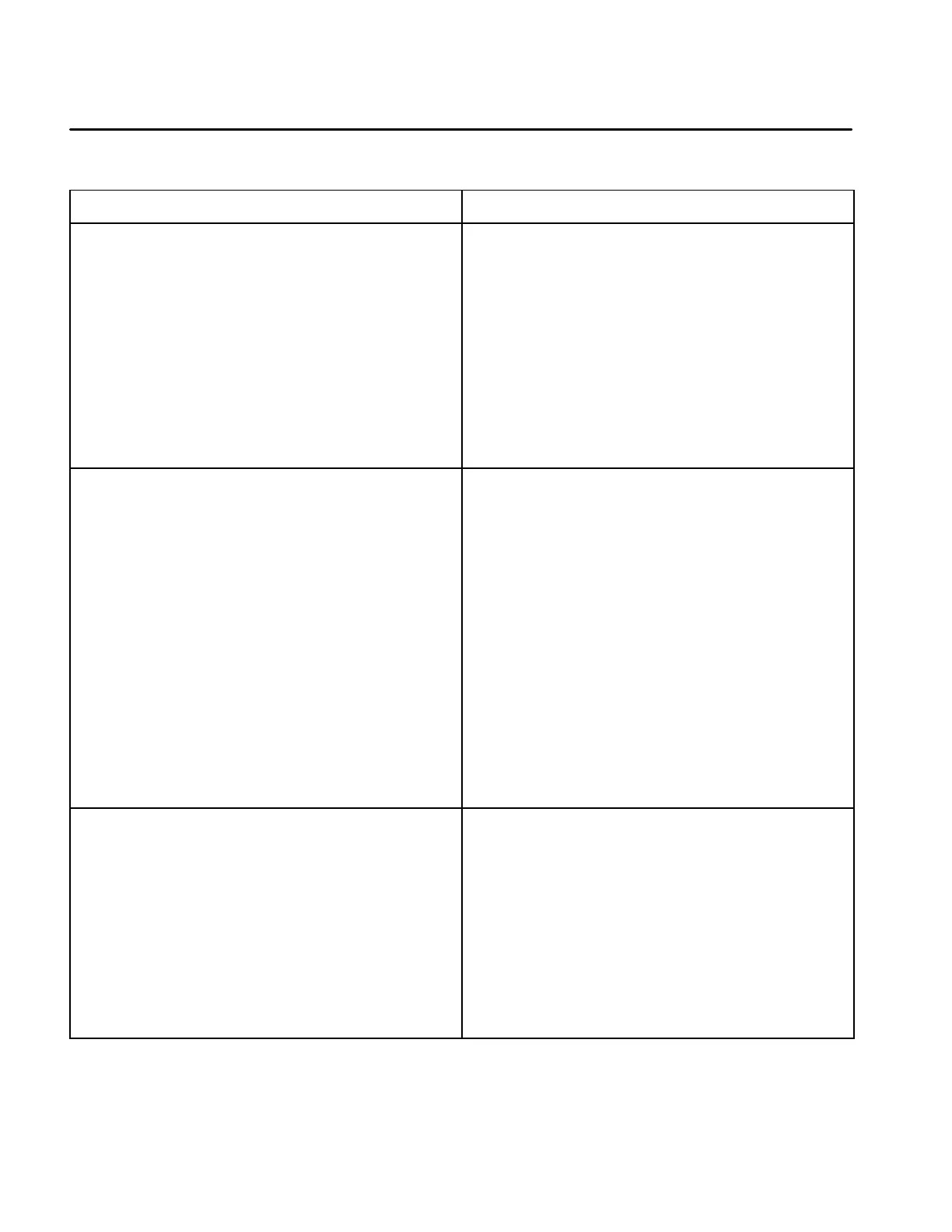

Transaxle

Problem Possible Causes

Noisy operation. Low oil level in transaxle.

Damaged or worn transaxle bearings.

Transaxle gears worn, scuffed or broken.

Excessive end play in transaxle countershaft.

Transaxle gears loose on shaft.

Excessive wear of differential side gear liners and

pinion liners in transaxle.

Excessive wear of splined slider on axle drive joints.

Difficult shifting. Clutch not releasing fully.

Shift cable out of adjustment.

Shift cable damaged.

Range selector cap screw loose (at operator console).

Cable clamp securing cables near range selector is

loose.

Loose shift lever on transaxle.

Sliding gear tight on transaxle shaft or splines.

Synchronizing unit in transaxle damaged.

Sliding gear teeth in transaxle damaged.

Synchronizer keys in transaxle damaged.

Gears make clashing noise when shifting. Operator is shifting too fast.

Excessive wear of synchro rings in transaxle.

Excessive wear of differential side gear liners and

pinion liners in transaxle.

Damaged synchro springs and/or keys in transaxle.

Main gear needle bearings in transaxle are worn or

damaged.

Excessive wear of driveshaft(s).

Loading...

Loading...