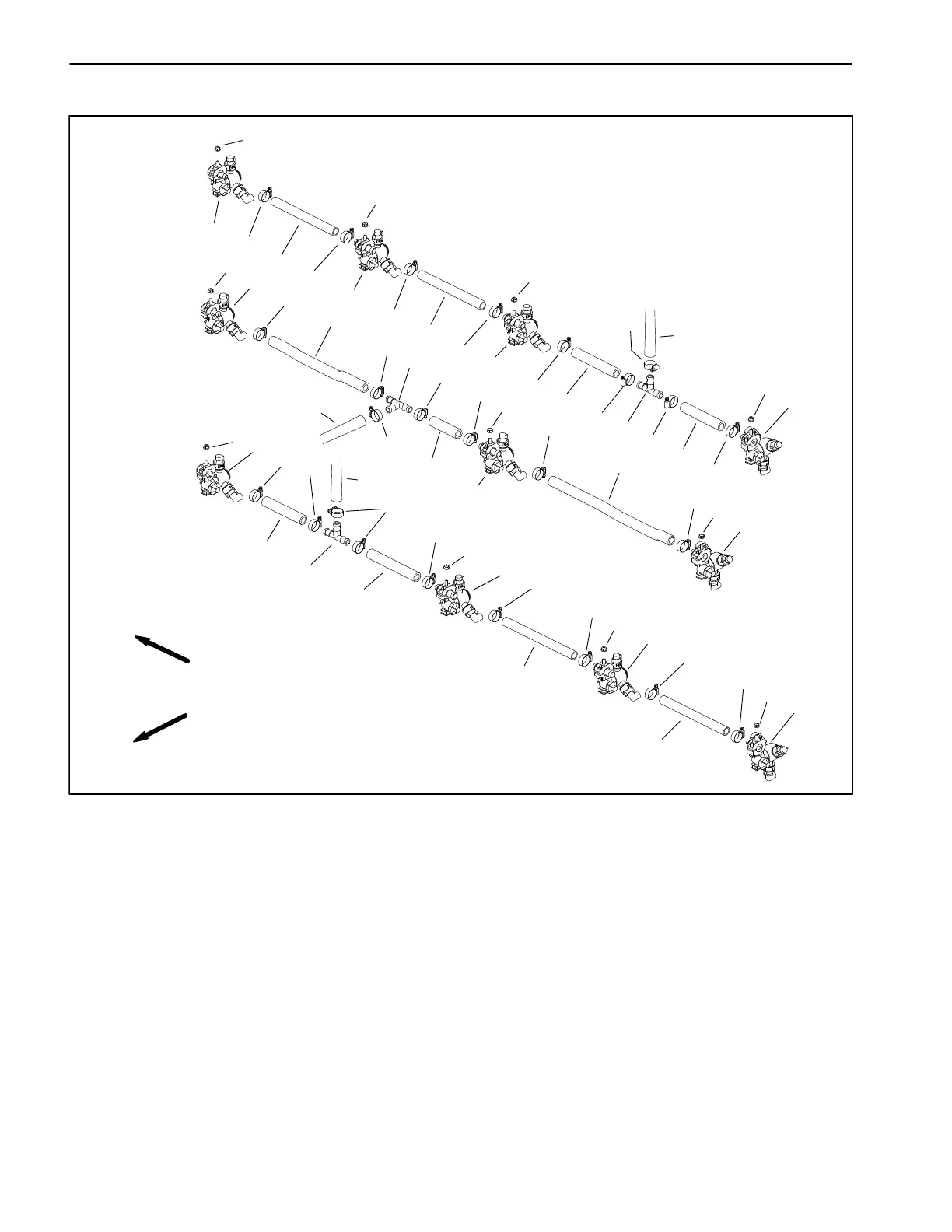

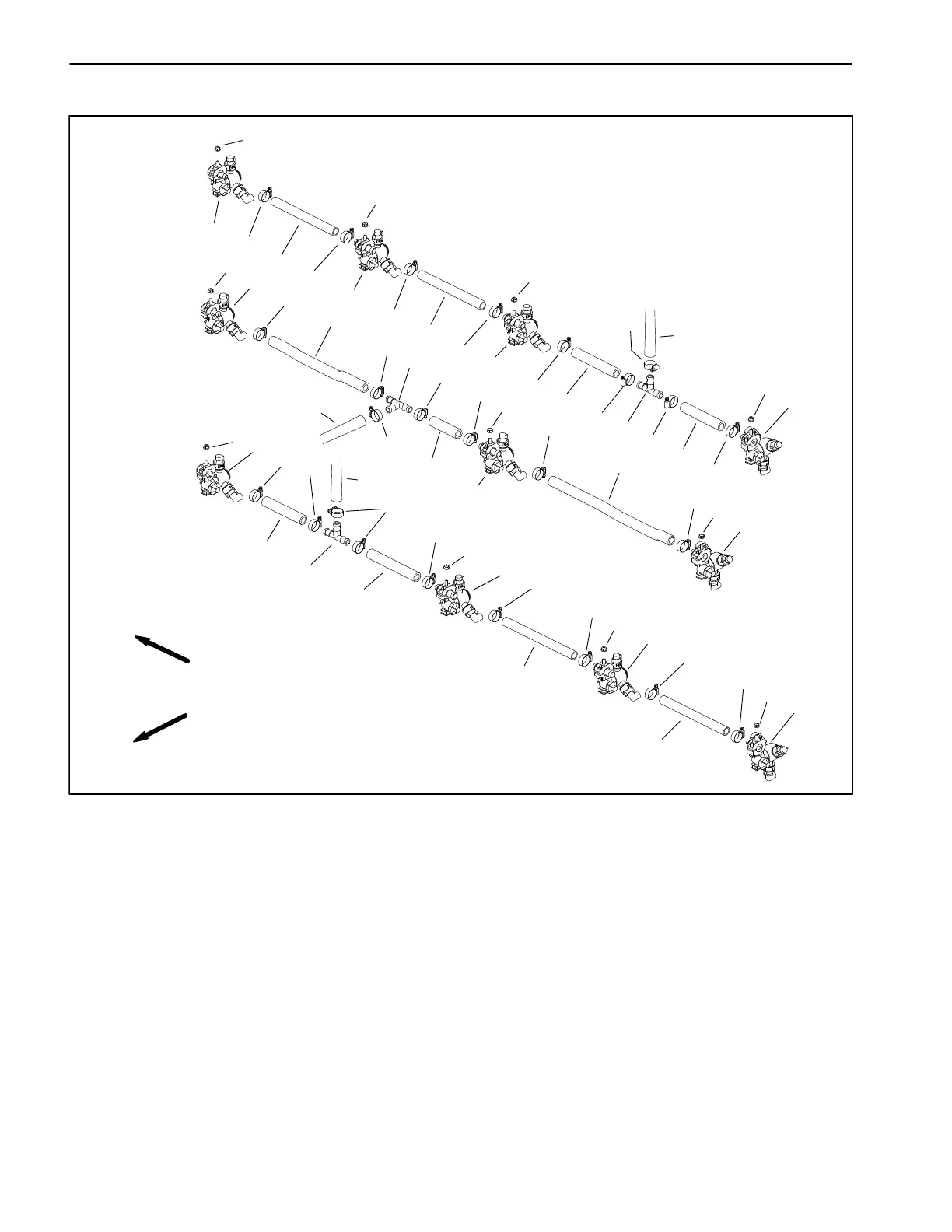

Multi Pro 1750Page 6 − 48Spray System

Turret Bodies

1. Flange nut (11)

2. Turret body − RH barb (3)

3. Turret body − LH barb (3)

4. Turret body − dual barb (5)

5. Tee fitting (3)

6. Hose clamp (25)

7. Hose 18.75” (47.6 cm) (4)

8. Hose 12.25” (31 cm) (2)

9. Hose 6” (15.2 cm) (2)

10. Hose 4.12” (10.5 cm)

11. Hose − formed RH

12. Hose − formed LH

13. Hose (from left boom spray valve)

14. Hose (from center boom spray valv

15. Hose (from right boom spray valve)

Figure 32

FRONT

RIGHT

RIGHT

BOOM

LEFT

BOOM

CENTER

BOOM

1

2

3

4

10

11

12

14

15

1

1

1

1

1

1

1

1

1

1

2

2

3

3

4

4

4

4

5

5

5

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

7

7

7

7

8

8

9

9

13

Removal (Fig. 32)

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disas-

sembly. Wear protective clothing, chemical resist-

ant gloves and eye protection during repair.

1. Park machine on a level surface, stop spray pump,

stop engine and engage parking brake. Remove key

from ignition switch.

2. Loosen hose clamp(s) and remove supply hose(s)

from turret body.

3. Remove flange nut (item 1) that secures turret body

to mount bracket and remove turret body from machine.

Installation (Fig. 32)

NOTE: The position of the hose barb on the turret body

determines the turret body’s location on the spray boom.

1. Position turret body to mount bracket on spray boom

and secure it in place with flange nut (item 1).

2. Install supply hose(s) to turret body. Tighten hose

clamp(s).

Loading...

Loading...