Multi Pro 1750 Page 7 − 21 Drive Train

Transaxle Service

Transaxle Disassembly

1. Thoroughly clean outside surface of transaxle.

NOTE: Item numbers in figures are shown in order of

disassembly; for example, remove item 1 first, then item

2, etc. Assemble in reverse order; for example, install

item 1 last.

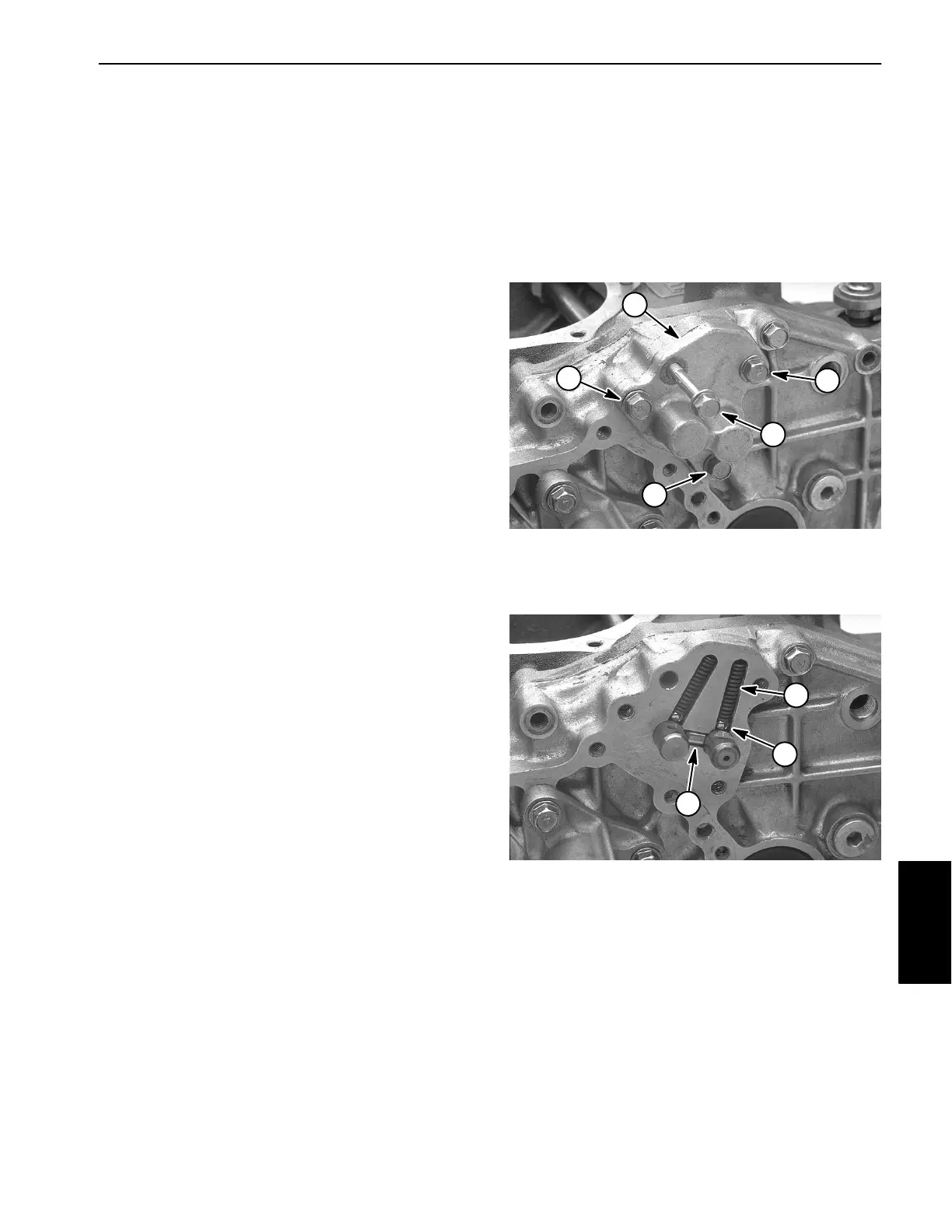

2. Loosen flange head screws and remove fork shaft

case from center plate. Note location of longer flange

head screw. Be careful when removing cover as steel

balls inside are spring loaded.

1

3

2

2

2

1. Flange head screw (1)

2. Flange head screw (3)

3. Fork shaft case

Figure 16

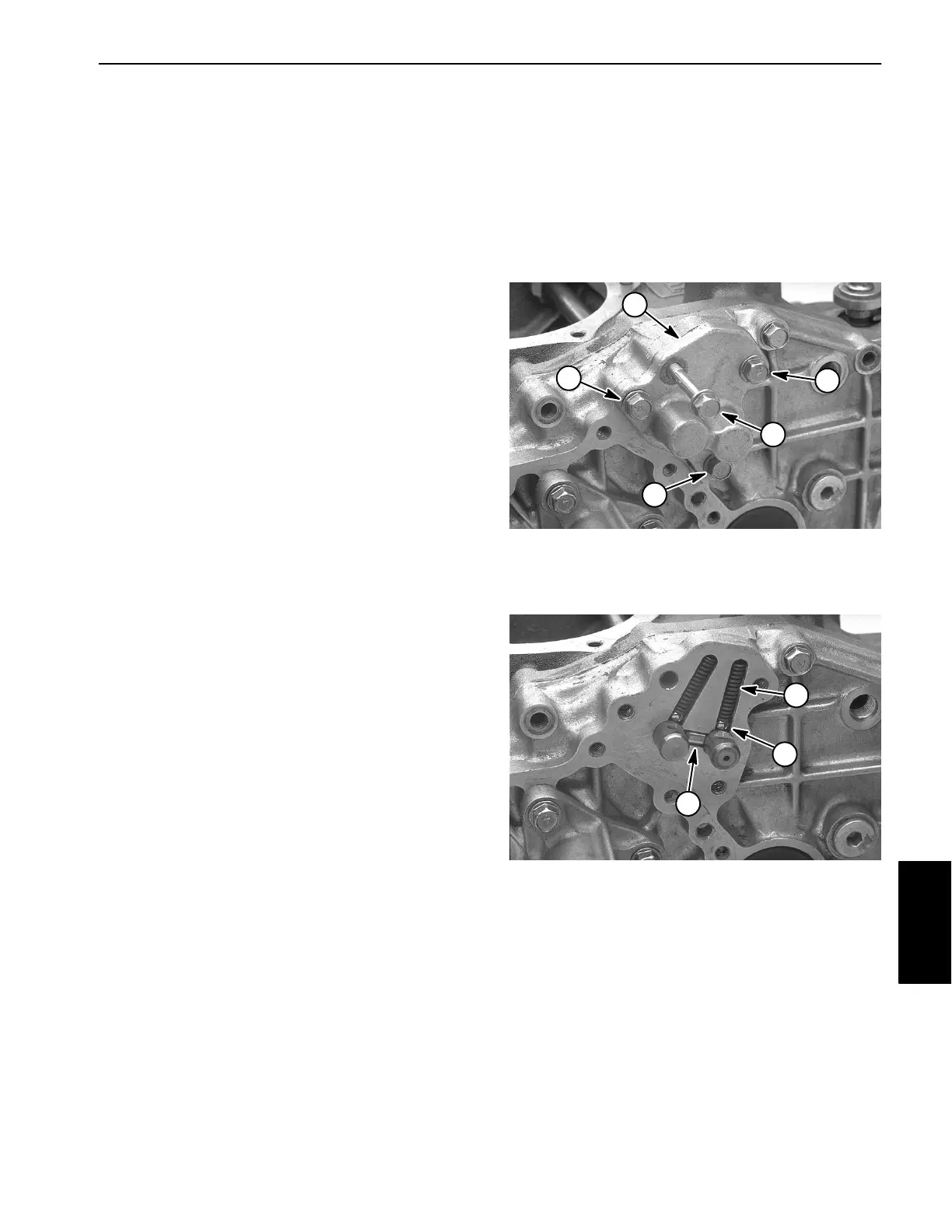

3. Hold your hand over the area and shift R−1 and 2−3

levers to move rails outward so balls, springs and

spindle can be removed.

4. Inspect fork shaft case for cracks or damage and re-

place if necessary.

1

2

3

1. Spindle

2. Spring (2)

3. Ball (2)

Figure 17

Drive Train

Loading...

Loading...