Multi Pro 1750Page 6 − 2Spray System

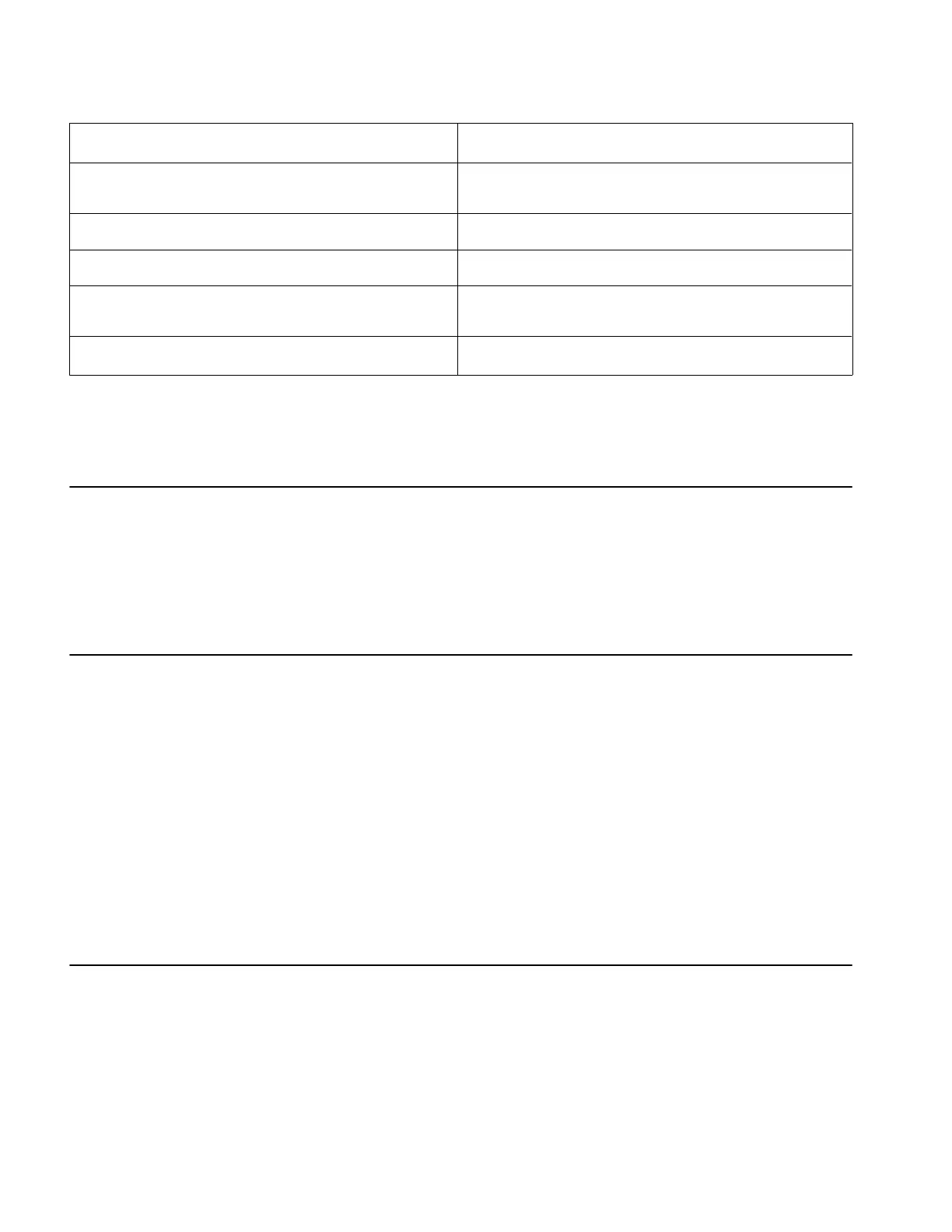

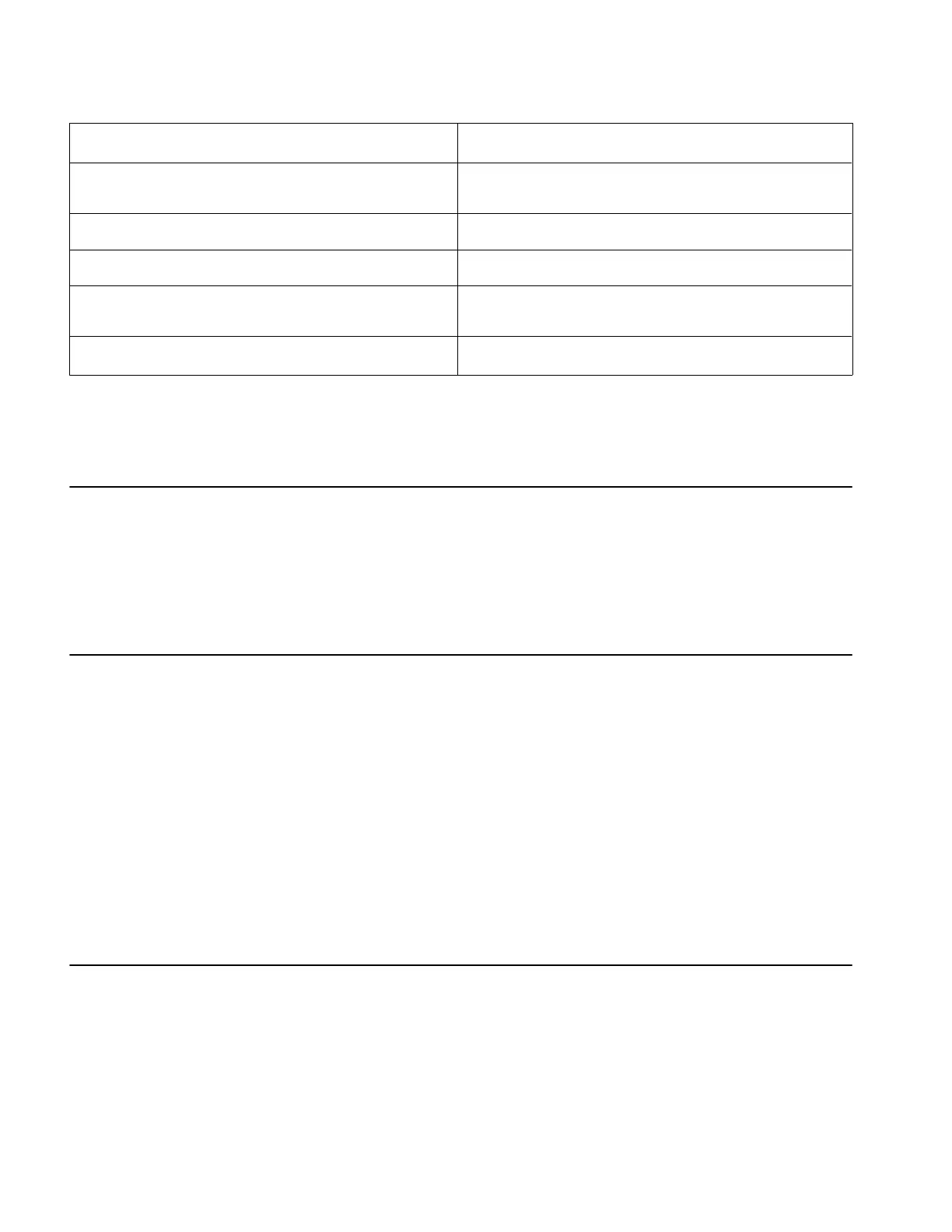

Specifications

Item Description

Spray Pump 6−Diaphragm, Positive Displacement Pump

Maximum Flow Rate of 45 GPM

Spray Pressure Relief Valve Poppet Style, 218 PSI (15 Bar) Maximum

Sprayer Tank 175 Gallon, Polyethylene

Suction Strainer 50 Mesh (Blue), Stainless Steel, Tank Mounted

(30 Mesh (Red) and 80 Mesh (Green) Optional)

Pressure Filter (Serial Number Above 315000000) 80 Mesh, Agitation Manifold Mounted

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Multi Pro machine. Refer to that publi-

cation for additional information when servicing the ma-

chine.

Precautions Concerning Chemicals Used in Spray System

Chemicals can injure persons, animals, plants, soil and

other property. To eliminate environmental damage and

personal injury:

1. Select the proper chemical for the job.

2. Carefully read the directions printed on the chemical

manufacturer’s labels before handling chemicals. In-

structions on chemical manufacturer’s container labels

regarding mixing proportions should be read and strictly

followed.

3. Keep spray material away from skin. If spray material

comes in contact with a person, wash it off immediately

in accordance with manufacturer’s recommendations

(refer to container labels and Material Safety Data

Sheets).

4. Always wear protective clothing, chemical resistant

gloves, eye protection and other personal protective

equipment as recommended by the chemical manufac-

turer.

5. Properly dispose of chemical containers, unused

chemicals and chemical solution.

Precautions for Removing or Adjusting Spray System Components

1. Stop the vehicle and set the parking brake.

2. Shut off the vehicle’s engine and remove the key

from the ignition switch.

3. Disengage all power and wait until all moving parts

have stopped.

4. Remove chemicals from pump, hoses and other

spray components. Thoroughly neutralize and rinse

spray system before loosening or removing any spray

system component(s).

5. Make sure system pressure is relieved before loos-

ening any system component (e.g. spray valves, spray

system hose).

Loading...

Loading...