Appendix A: Ordering Genuine Ithaca Supplies

100-11672 - Rev D Page 137

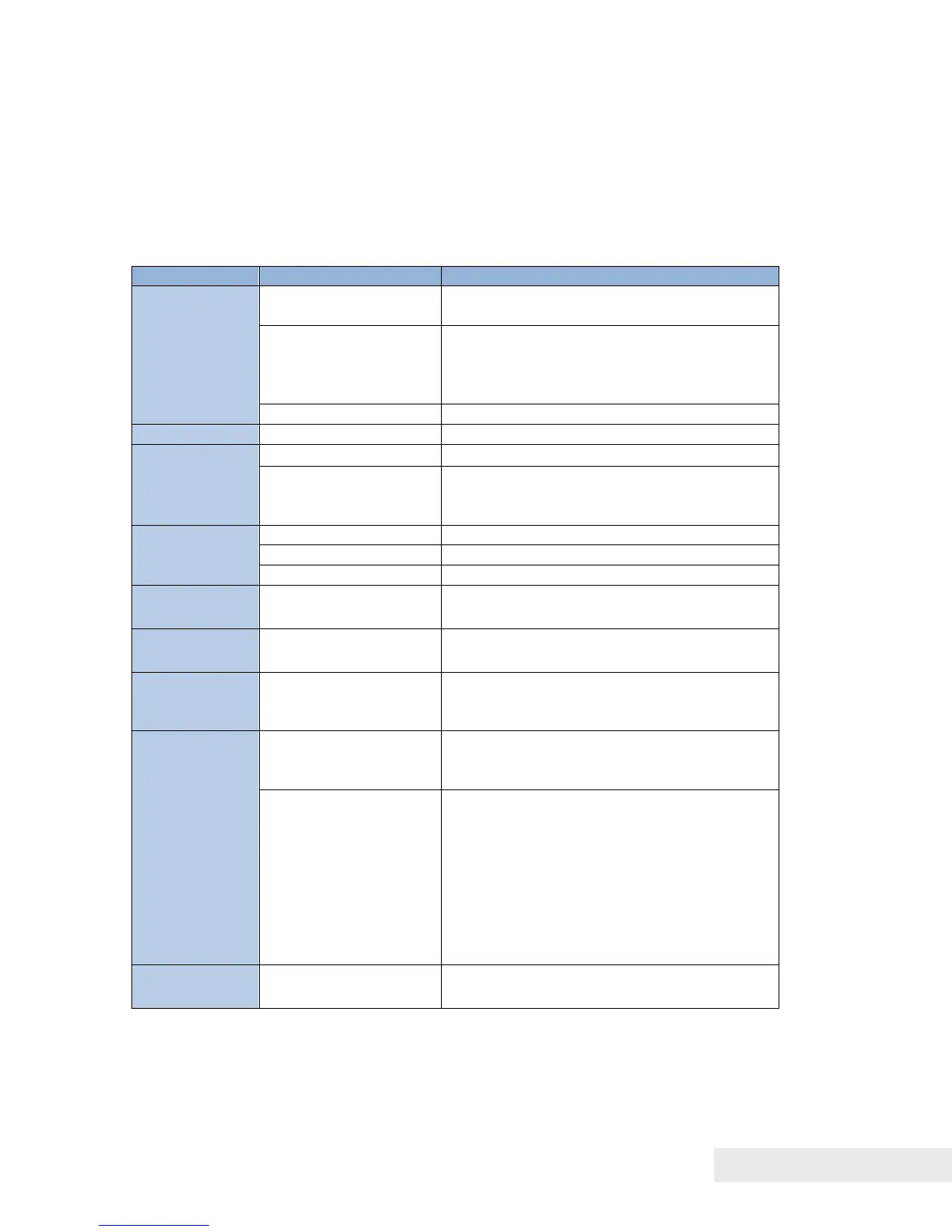

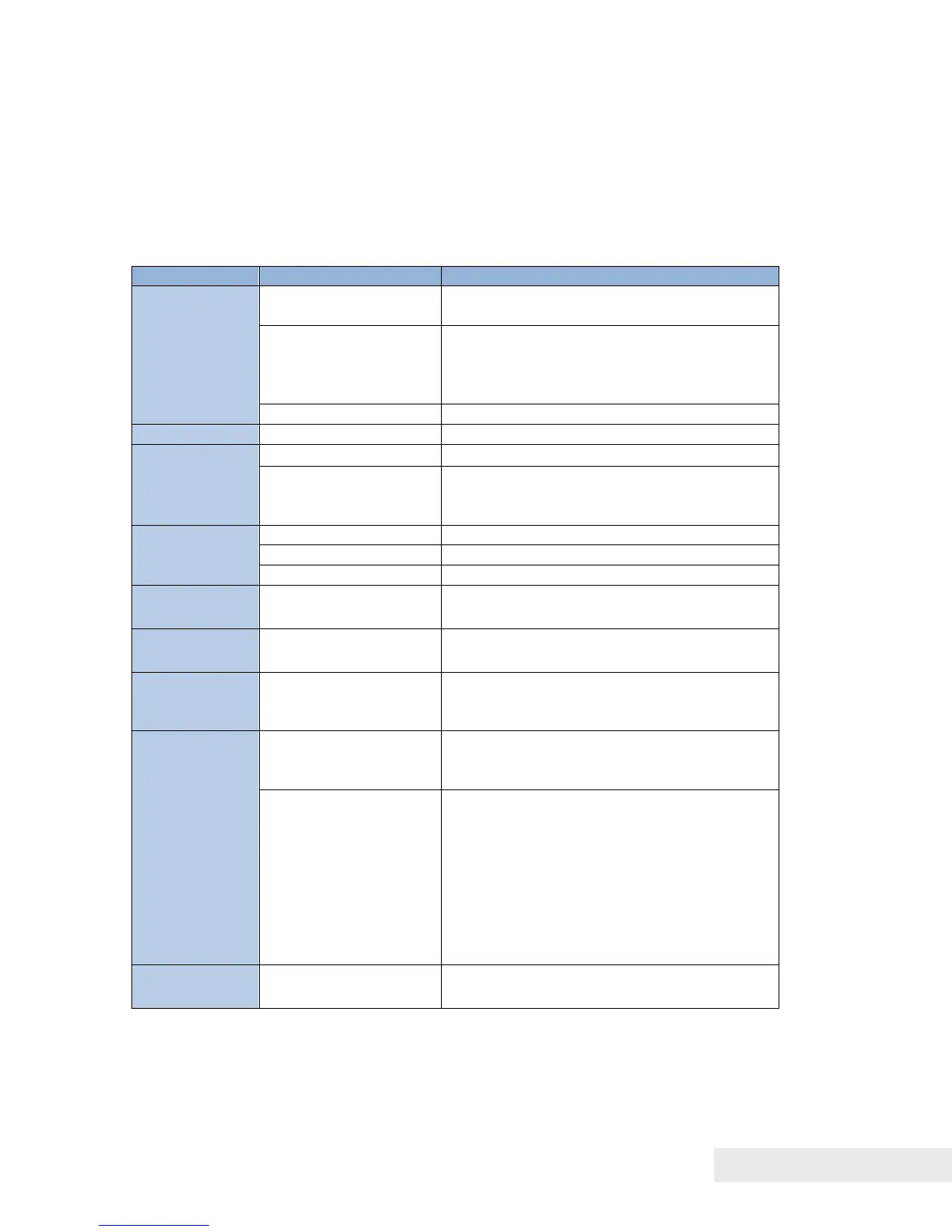

Adjustment

Adjustment When Replacing Parts

This section describes the works to be carried out, as an after-sale service,

after parts replacement.

Reference section in manual

"Work at Print Module Replacement"

Input of various

adjustment values

(*1) (Indicated on

labels)

"Print Module Replacement Procedure"

"Head Position Adjustment"

"Head Position Adjustment"

"Blade Position Adjustment"

Input of Purge Unit

wipe position

(Indicated on label)

"Consumable Parts Replacement

Procedure"

"Pinch Roller Position Adjustment"

"Head Position Adjustment"

"Backfeed Gap Adjustment"

"Work at Rack Unit Replacement"

Lift Unit / Rear

Feeder sensor

"Rear Feeder Sensor Adjustment"

Stacker Rail /

Front Tray

Unit

"Work at Stacker Rail and/or Front Tray

Unit Replacement"

In the case data can

be retrieved (Send

the data to Printer )

"• In the case data can be retrieved from

Printer Controller PCB to PC."

In the case data can

be retrieved (serial

number, time, various

adjustment values

(*1), Rear Feeder

Sensor, ink eject

power, Printhead

position, backfeed

gap)

"• In the case data cannot be retrieved

from Printer Controller PCB to PC."

"DC Power Supply Unit Replacement

Procedure"

(*1) Printhead wipe position, Printhead capping position, Printhead print

position, and Purge Unit wipe position

(*2) T-K gap, slant, and Head position

(*3) Use adjustment tool (supplied with service parts).

Loading...

Loading...