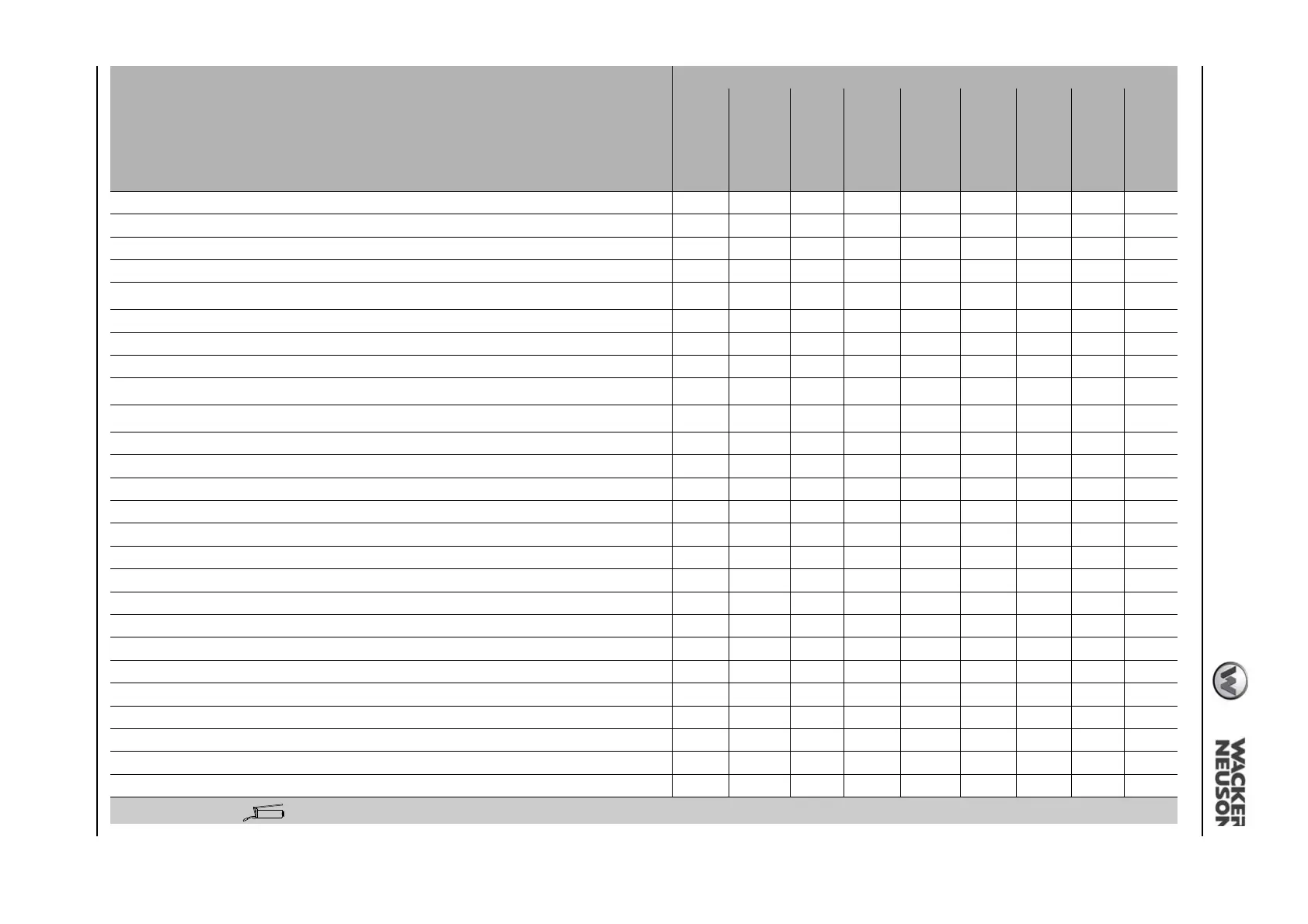

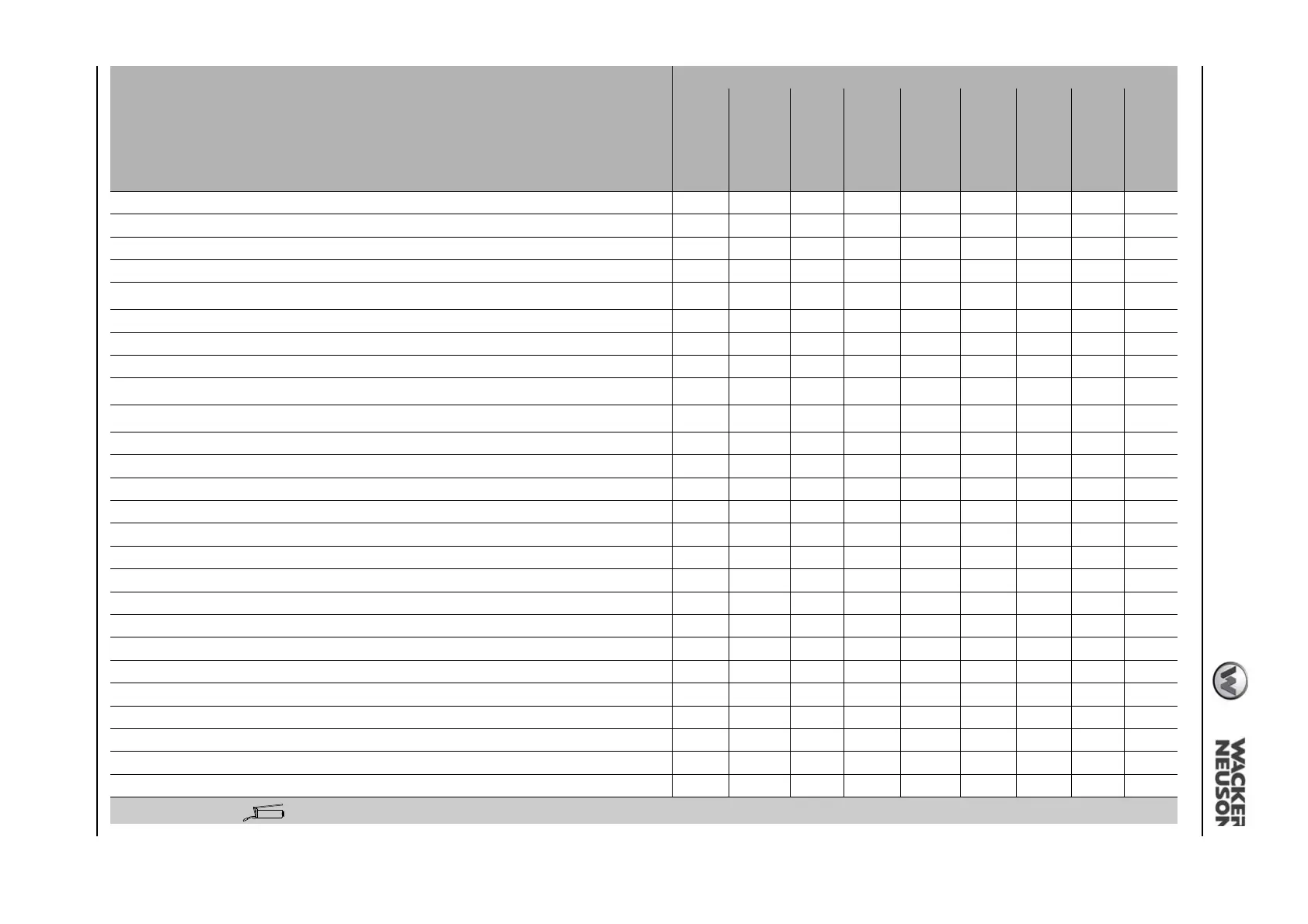

5-38 BA 901/1101 en – Edition 2.1 * 91101b540.fm

Maintenance plan (overview)

Exhaust gas turbocharger: clean compressor outlet

●●

Check valve clearance and adjust every 1500 o/h if necessary

●●

Check the fuel injection pump

●●

Check the injection pressure

●●

Check the injection nozzles

8

● ●

Replace fuel injectors

●●

Empty the diesel fuel tank (to avoid condensation water)

●

●

Check battery fluid, add distilled water if necessary, check for leaks, visual check

●●

Check alternator, starter and electric connections, bearing play and function

9

●●

Preheating system, electric connections

10

(replace heater plugs every 2 years)

●●

Check wheels/tracks for cracks, cuts, check profile and air pressure

●●

Check wheel nuts

●●

Check track tension. Retighten if necessary

●●

Check bearing play of tread rollers, track carrier rollers, front idlers

●●

Check piston rods for damage

●●

Check screws for tightness

●● ●

Pin lock

●●

Attachment of lines (replace clamps if damaged)

●●

Engine and engine suspension (replace suspension if damaged)

●

Check indicator lights for correct function

●● ●

Tilt lock and gas strut of cabin

●● ●

Couplings, dirt pile-up on hydraulic system dust caps

●●

Check insulating mats in the engine compartment for damage/attachment

●● ●

Adhesive labels and Operator’s Manual

●● ●

Engine cover gas strut

●●

Pressure check of travel and operating hydraulics

●● ●

Lubrication service ( ):

5.20 Maintenance plan (overview)

Work description

For service and maintenance on the attachment, please refer to the operation and maintenance

manual of the attachment manufacturer as well.

Maintenance plan/operating hours (o/h)

Maintenance

(once a day)

Every 50 o/h

Every 250 o/h

Every 500 o/h

Every 1000 o/h

once a year

Every 1500 o/h

Every 3000 o/h

or 5 years max.

Customer

Wacker Neuson

service center

Loading...

Loading...