BA 901/1101 en – Edition 2.1 * 91101b540.fm 5-39

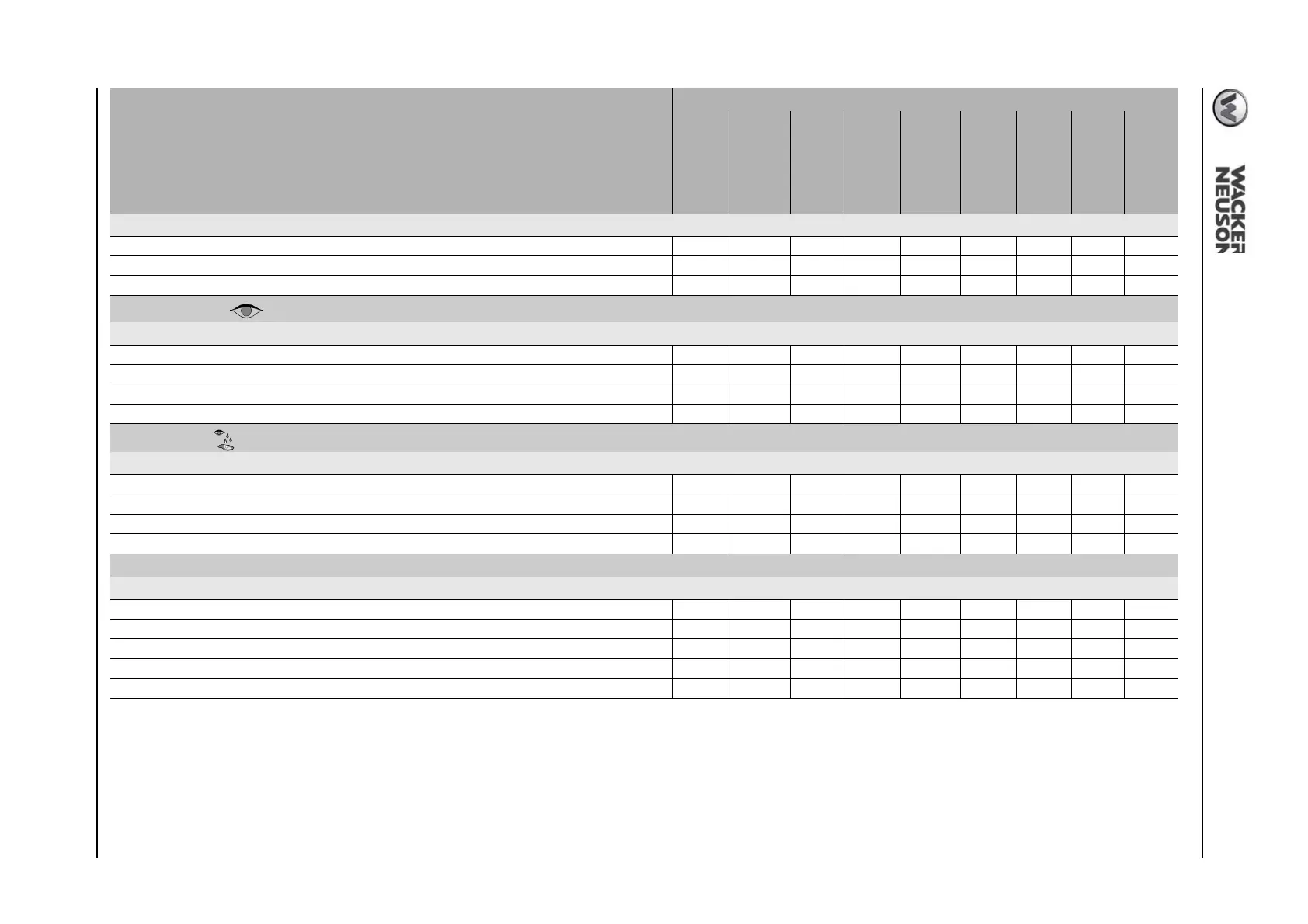

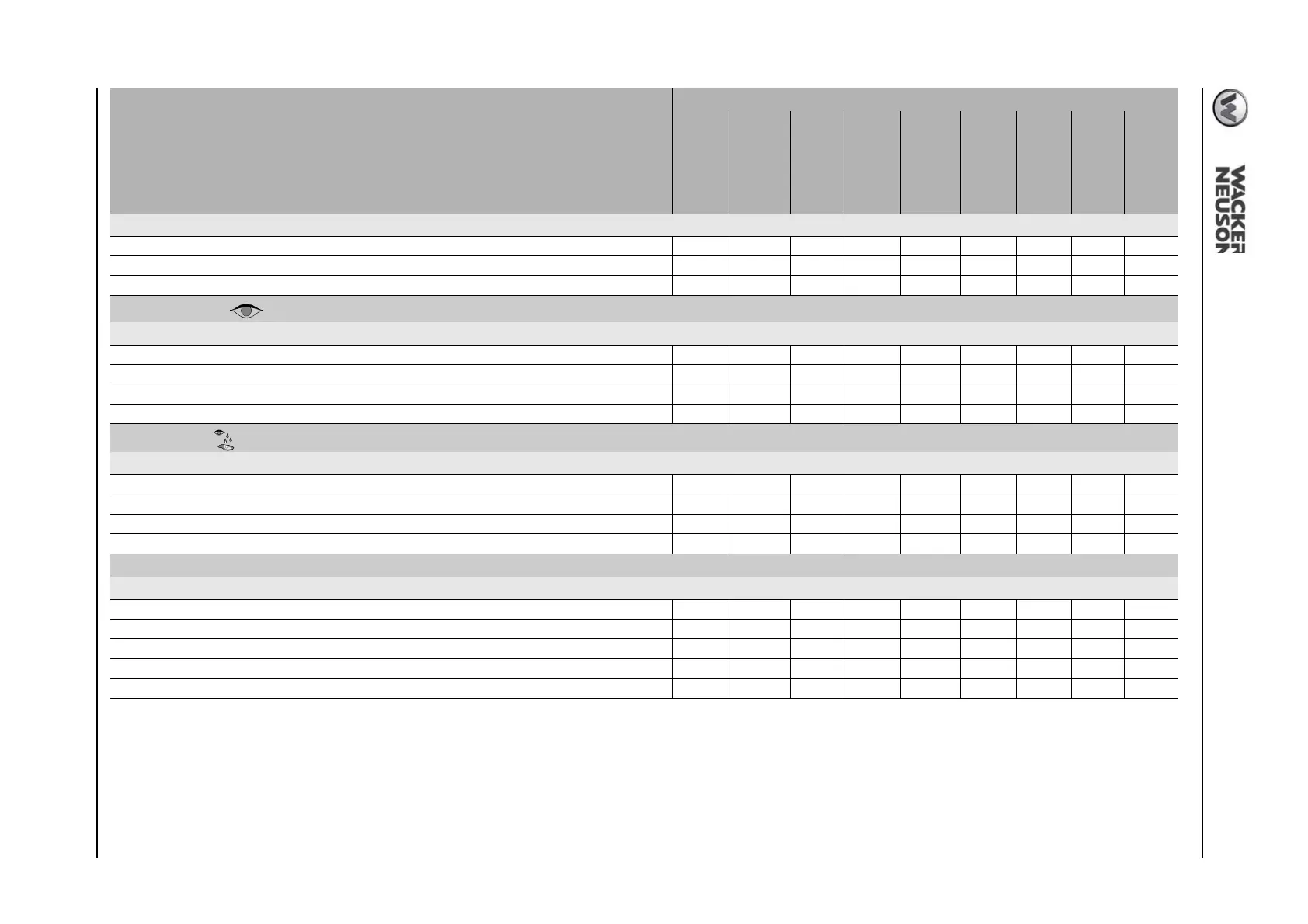

Maintenance plan (overview)

Lubricate the following assemblies/components – see Traveling drive on page 5-26:

• Quickhitch ●●

• Mobile parts of lock mechanism ●●

• Attachments ●●

Functional check ( ):

Check the function of the following assemblies/components. Rectify if necessary:

• Lights, signaling system, acoustic warning system ●●

• Check function of safety bars, check for damage ●●

• Check emergency lowering ●●

• Safety device: maintenance prop of loader unit ●●

Leakage check ( ):

Check for tightness, leaks and chafing: pipes, flexible lines and threaded fittings of the following assemblies and components. Rectify if necessary:

• Visual check ●●

☞ Engine and hydraulic system ●●

☞ Cooling and heating circuit ●●

☞ Traveling drive ●●

Air conditioning:

Check the function of the air conditioning, repair if necessary:

☞ Air conditioning function ●● ●

☞ Replace the cabin filter ●●

☞ Check dehumidifier for corrosion, condensation and air bubbles ●●

☞ Replace dehumidifier ●●

☞ Compressor oil (replace the compressor oil every other 1500 o/h servicing) ●●

1. Drain engine oil the first time after 50 o/h, then every 500 o/h

2. Replace the engine oil filter the first time after 50 o/h, then every 500 o/h

3. Replace the fuel filter the first time after 50 o/h, then every 500 o/h

4. Replace the hydraulic oil filter insert the first time after 50 o/h, then every 500 o/h

5. Drain the gearbox oil the first time after 250 o/h, then every 1000 o/h

6. Check the gearbox oil every other 50 o/h servicing

7. Clean the water ducts every other 1000 o/h servicing

8. Check the injection nozzles and the valves every other 1500 o/h servicing

9. First check of alternator and starter at 50 o/h, then every 500 o/h

10. First check of preheating system at 50 o/h, then every 500 o/h

5.20 Maintenance plan (overview)

Work description

For service and maintenance on the attachment, please refer to the operation and maintenance

manual of the attachment manufacturer as well.

Maintenance plan/operating hours (o/h)

Maintenance

(once a day)

Every 50 o/h

Every 250 o/h

Every 500 o/h

Every 1000 o/h

once a year

Every 1500 o/h

Every 3000 o/h

or 5 years max.

Customer

Wacker Neuson

service center

Loading...

Loading...