Weber Packaging Solutions, Inc.

8

Troubleshooting

This chapter covers diagnostic and troubleshooting information. It

explains how to use the built-in diagnostic tools and covers common

problems, possible causes and solutions.

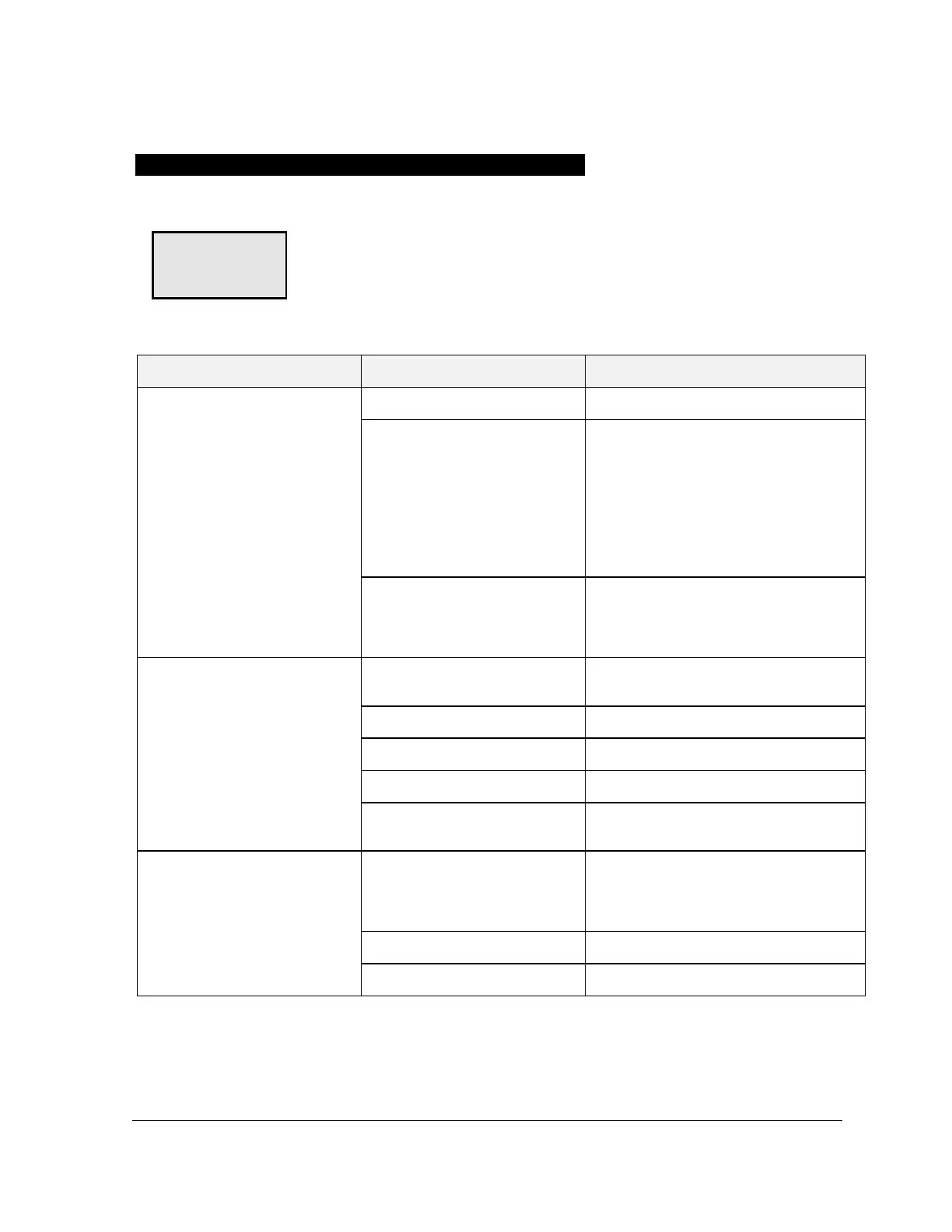

Incorrectly threaded labels.

Damaged roll of labels:

Nicks or label cutter die damage

on liner.

Bruise on the side of the label

roll.

Liner width varying significantly.

Adhesive buildup on peeler bar.

Clean as necessary and examine label

roll for damage. A damaged roll can

cause excessive buildup. Replace label

roll if necessary.

Labels are not being held onto

the tamp pad. Label placement

on the tamp pad is consistently

poor.

Vacuum pump not operating.

Check for air coming out of the muffler.

Repair/replace as needed.

Refer to setup instructions.

Air assist too high or too low.

Refer to setup instructions.

Air assist tube out of position.

Refer to setup instructions.

Tamp pad holes not punched

out.

Refer to setup instructions.

Label placement on the product

consistently poor.

Product is inconsistently

presented to the tamp pad.

Check to make sure that the conveyor

speed is constant. Adjust guide rails or

other product control devices to present

the product in a consistent manner.

Incorrect tamp extend time.

Refer to setup instructions.

Air-Blast too high or too low.

Refer to setup instructions.

Loading...

Loading...