Chapter 8

8-2 Printer-Applicator User’s Manual

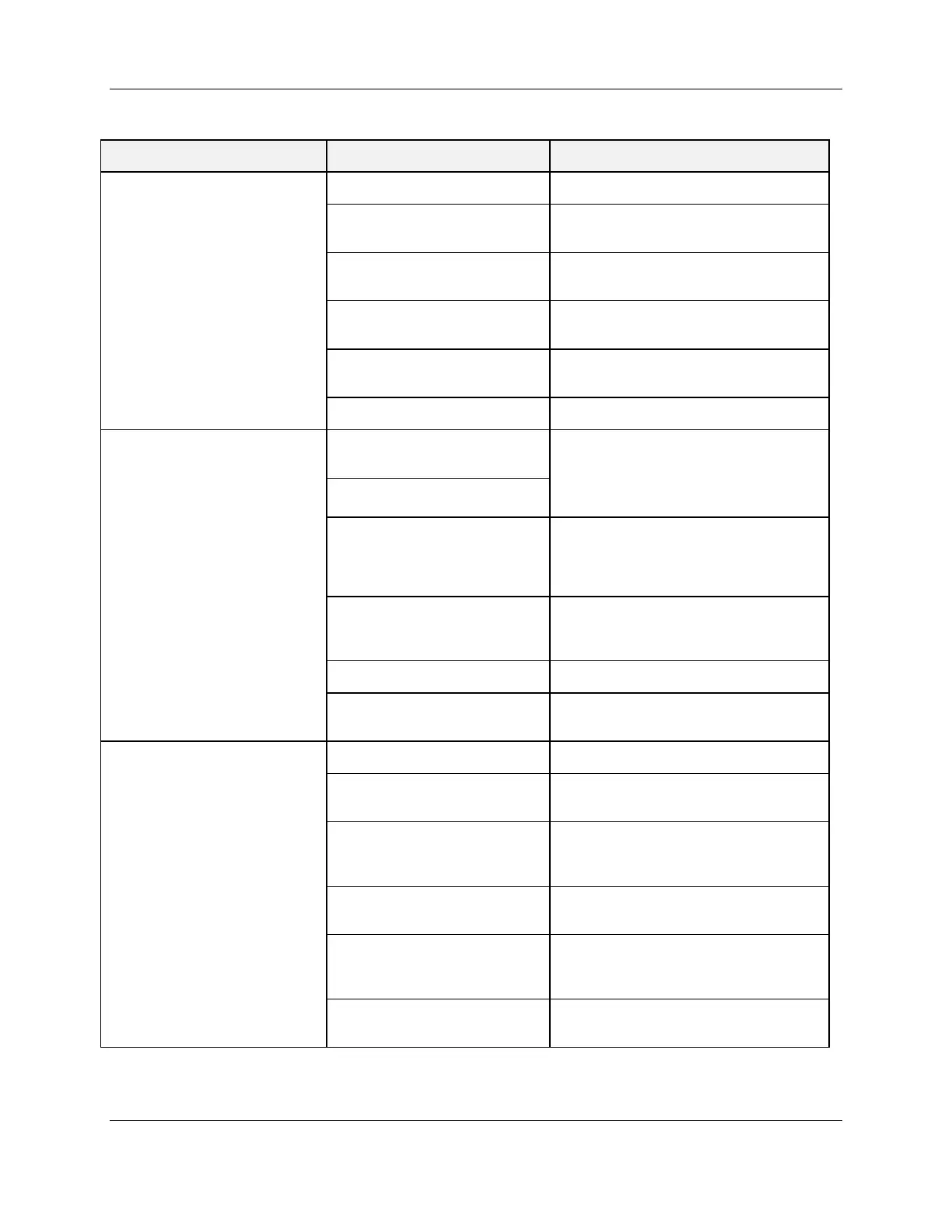

Label placement on the product

consistently poor.

Incorrect Air-Blast time.

Refer to setup instructions.

Product detector sensitivity out

of adjustment.

Refer to setup instructions.

Product detector or reflector

loose and vibrating.

Refer to setup instructions.

Marginal detector position or

adjustment.

Refer to setup instructions.

Fluctuation in product conveyor

speed.

Poor quality of label adhesive.

Air assist does not function or is

ineffective.

Air assist flow too low or too

high.

Refer to setup instructions.

Air assist tube incorrectly

positioned, damaged or

disconnected.

Examine, adjust, repair, or replace as

necessary.

Labels incorrectly threaded.

Refer to setup procedures. Make sure

that the label liner is threaded between

the air assist tube and the peeler bar.

Air assist solenoid malfunction.

Examine and replace if necessary.

Applicator controller

malfunction.

Request qualified assistance.

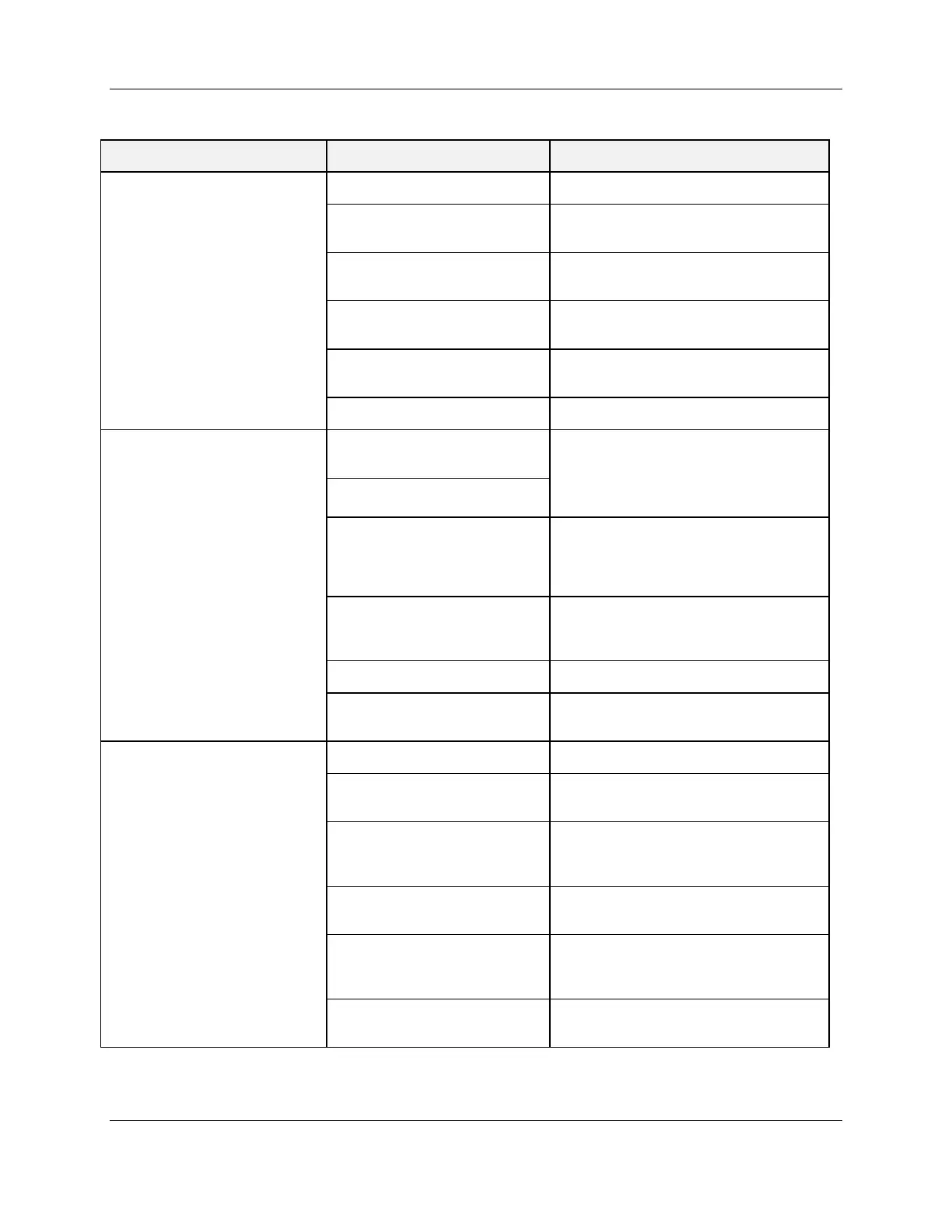

Clear obstruction and re-thread labels.

Tamp home switch not

functioning.

Adjust the switch or replace if defective.

No product detection. Product

detector I/O board jumpers not

configured correctly.

Re-adjust the product detector; replace if

defective. Check JMP2 settings on I/O

board, see Chap. 9, Appendix for details.

Incorrect print engine parameter

values.

Refer to the print engine manual for more

information.

Send label printing information to the

print engine buffer. (See print engine

manual for more information.)

Applicator still in Idle mode.

Press [] on controller to enter Run

mode.

Loading...

Loading...