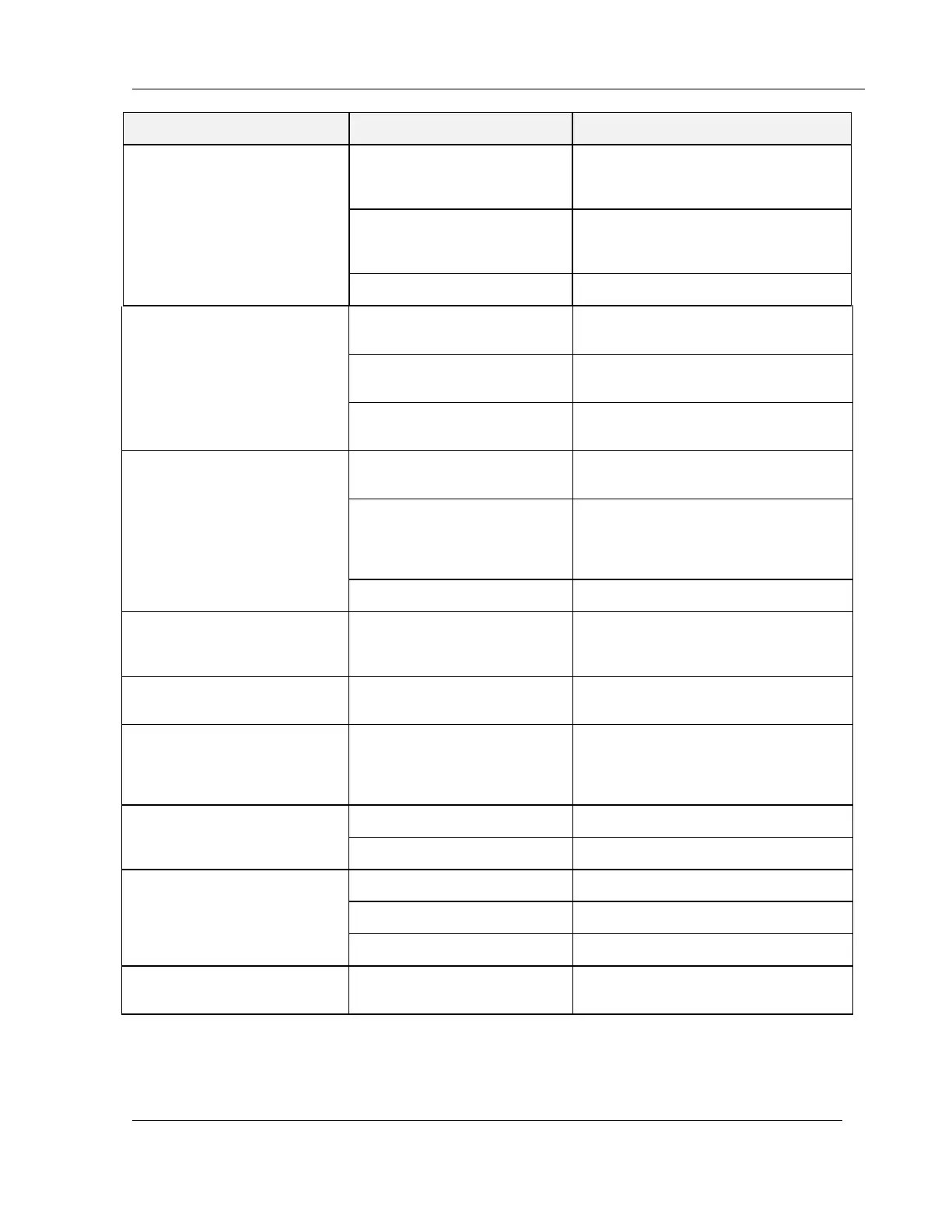

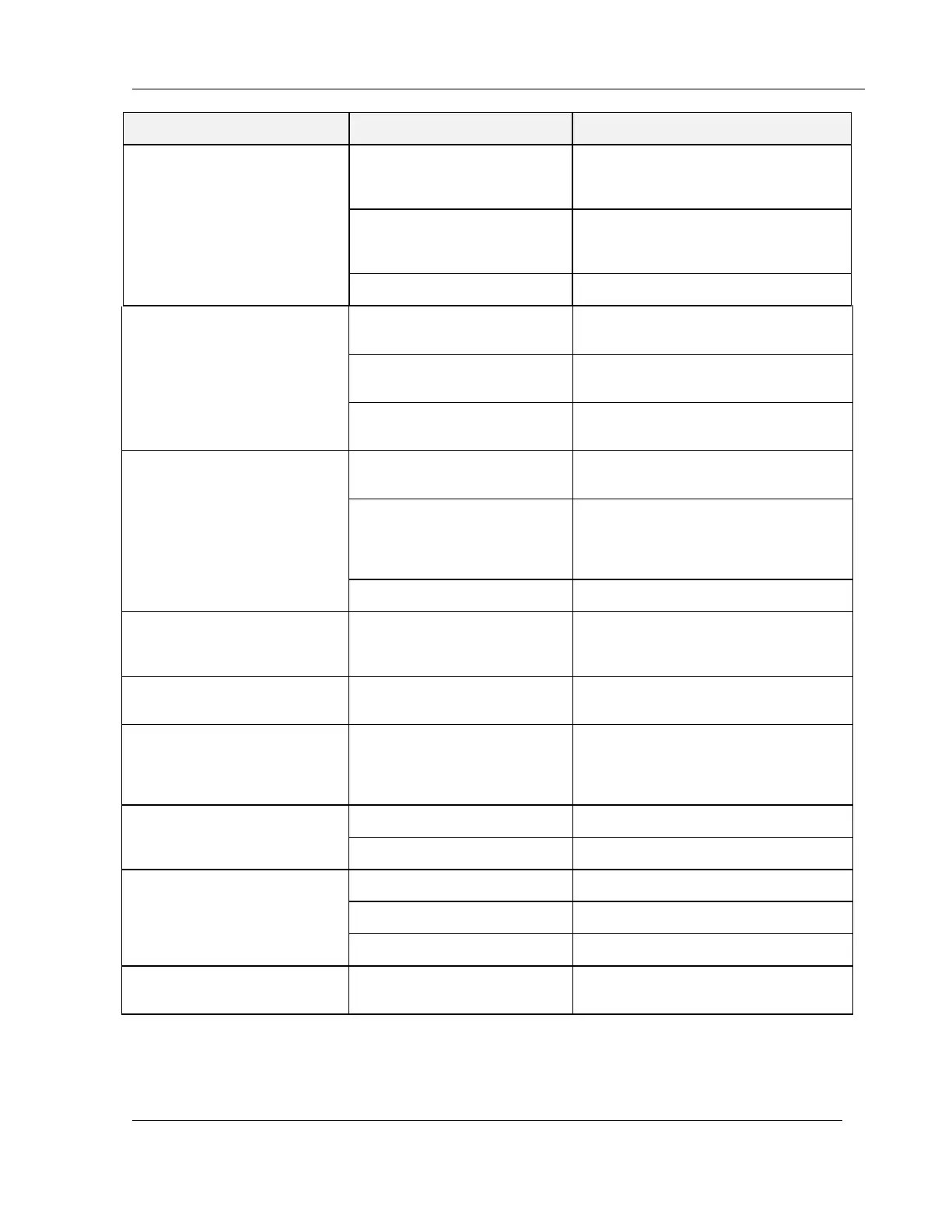

Troubleshooting

Weber Packaging Solutions, Inc. 8-3

Label application rate unable to

keep up with the product rate.

Product conveyor running too

quickly for label application rate.

Check machine specifications for rate

versus size of label being applied. Slow

down conveyor if necessary.

Excessive printer processing

time.

Check the software and compiling/editing

time, and print speed. (See print engine

manual for more information.)

Incorrect setup adjustments.

Refer to setup instructions.

Machine functions occur at

random without being initiated.

Product detector loose or

vibrating.

Investigate and correct as necessary.

Product detector alignment or

adjustment is marginal.

Refer to setup instructions.

Loose wiring connections.

Check all wiring connections. If

necessary request qualified assistance.

Tamp home sensor is broken or

out of adjustment

Replace or adjust sensor as needed.

Print engine configuration

incorrect.

Make sure that all the required parameter

values are correctly entered in the print

engine. Refer to the print engine manual

for more information.

Load print information into the buffer.

Compressed print on labels in

the feed direction.

Applicator unwind brake

preventing labels from

unwinding properly.

Reduce the tension of the dancer arm

brake.

Refer to the print engine

manual.

Refer to the print engine manual.

Labels print continuously without

being applied.

Print engine configuration

incorrect.

Make sure that all the required parameter

values are correctly entered in the print

engine. Refer to the print engine manual

for more information.

Air-Blast does not occur.

Air-Blast time too short.

Refer to setup instructions.

Air-Blast solenoid malfunction.

Investigate and replace if necessary.

Label fails to leave the tamp.

Refer to setup instructions.

Refer to setup instructions.

Rewind motor stalls and fails to

rewind label liner waste.

Rewind sensor flag is out of

alignment.

Refer to Rewind Sensor Flag Adjustment

section in Chapter 8.

Loading...

Loading...