Maintenance and repair en

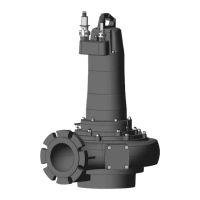

Installation and operating instructions Wilo Motor FK 17.1, FK 202, FK 34, FK 42 + EMU FA, Rexa SUPRA, Rexa SOLID 181

3. Spray the pump with clear water from top to bottom. NOTICE!An appropriate dis-

infectant must be used for contaminated pumps! Strictly observe the manufac-

turer’s specifications concerning use!

4. To clean the impeller and the pump interior, guide the water jet inside via the pres-

sure port.

5. Flush all dirt residue onto the floor of the channel.

6. Allow the pump to dry out.

9 Maintenance and repair

DANGER

Danger due to fluids hazardous to health!

If the pump is used in fluids hazardous to health, decontaminate the pump after dis-

mantling and before carrying out any other work! There is a risk of fatal injury! Ob-

serve the specifications in the work regulations! The operator must make sure that

the personnel have received and read the work regulations!

NOTICE

Use only properly functioning lifting equipment!

Use only properly functioning lifting equipment to lift and lower the pump. Ensure

that the pump does not become jammed during lifting and lowering. Do not exceed

the maximum bearing capacity of the lifting equipment! Check that lifting equip-

ment is functioning properly before use!

▪Always carry out maintenance tasks in a clean location with good lighting. It must be

possible to position the pump safely and secure it.

▪Only carry out maintenance tasks mentioned in these installation and operating in-

structions.

▪Wear the following protective equipment while performing maintenance tasks:

– Safety goggles

– Safety shoes

– Safety gloves

9.1 Personnel qualifications

▪Electrical work: A qualified electrician must carry out the electrical work.

▪Maintenance tasks: The technician must be familiar with the use of operating fluids and

their disposal. In addition, the technician must have basic knowledge of mechanical en-

gineering.

9.2 Operator responsibilities

▪Provide the necessary protective equipment and make sure that the personnel wears it.

▪Collect operating fluids in suitable tanks and dispose of properly.

▪Dispose of protective clothing used in accordance with regulations.

▪Use only original parts of the manufacturer. Use of parts other than the original parts

releases the manufacturer from any liability.

▪Collect any leakage of fluid and operating fluid immediately and dispose of it according

to the locally applicable guidelines.

▪Provide the tools required.

▪If flammable solvents and cleaning agents are used, open flames, naked lights and

smoking are prohibited.

9.3 Labelling of the screw plugs

M

Motor compartment screw plugs

D

Sealing chamber screw plugs

K

Cooling system screw plugs

L

Leakage chamber screw plug

S

Condensation water chamber screw plug

F

Grease nipple screw plug

9.4 Operating fluid

Loading...

Loading...