5-11

POWR

E

INSPECTION

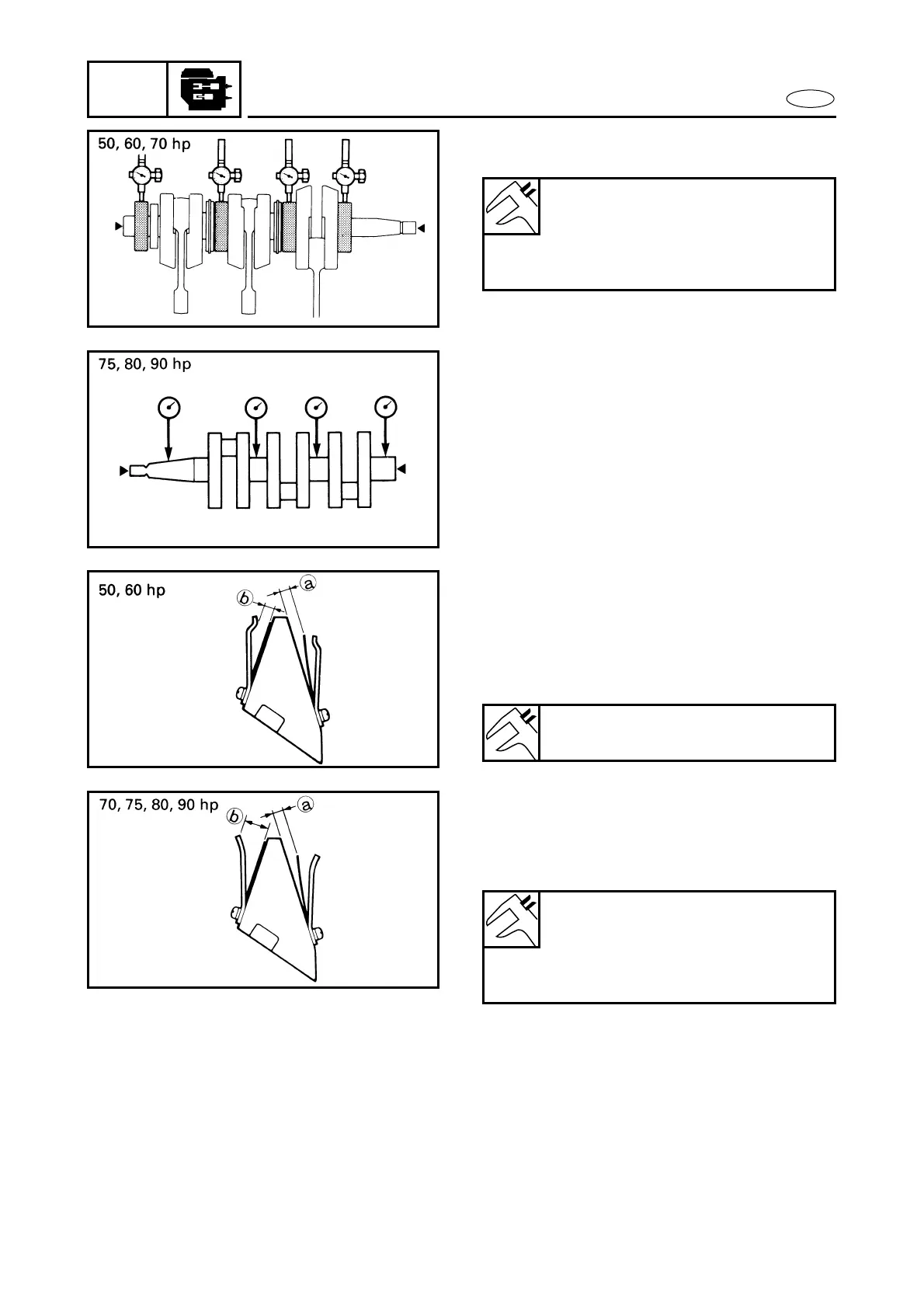

4. Using dial gauges, measure the deflec-

tion.

If the deflection is greater than the spec-

ified maximum, correct the alignment

by use of a copper hammer and a

wedge.

If the deflection is greater than the spec-

ified maximum, replace the crankshaft

assembly.

Maximum deflection:

50, 60, 70 hp:

0.03 mm (0.0012 in)

75, 80, 90 hp:

0.05 mm (0.0020 in)

G64000-0*

REED VALVE

INSPECTION

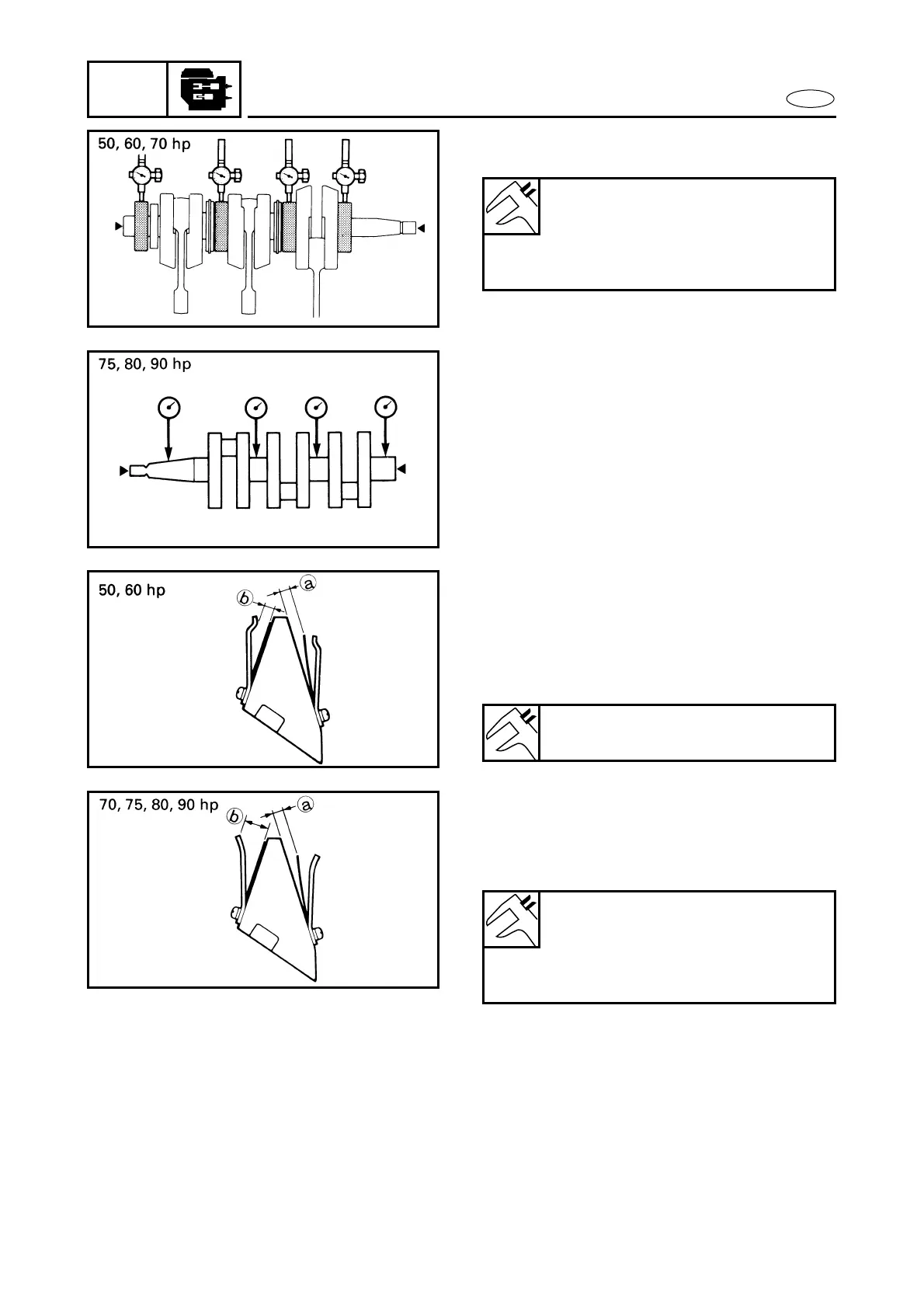

1. Visually inspect for warping of the reed

valve. If warped, measure the distortion

with feeler gauges.

If the amount of warping is greater than

the specification, replace the reed valve.

2. Using a vernier caliper, measure the

valve stopper height.

If the valve stopper height is outside the

specification, adjust it by bending it.

3. Visually inspect for cracks on the reed

valve. If cracks are found, replace the

reed valve.

Warpage limit a:

0.2 mm (0.01 in)

Valve stopper height b:

50, 60 hp:

3.0 ± 0.2 mm (0.12 ± 0.01 in)

70, 75, 80, 90 hp:

9.9 ± 0.2 mm (0.39 ± 0.01 in)

Loading...

Loading...