5-18

POWR

E

ASSEMBLY AND ADJUSTMENT

2. Lift the crank assembly a little in order

to install a washer on the lower crank-

case and align each location-pin of the

bearings and labyrinth-seals with each

cut on the cylinder-block. Then, fit the

crank assembly in place.

3. Film-coat the cylinder-block mating sur-

face with Gasket Maker or equivalent.

4. Install the dowel-pins.

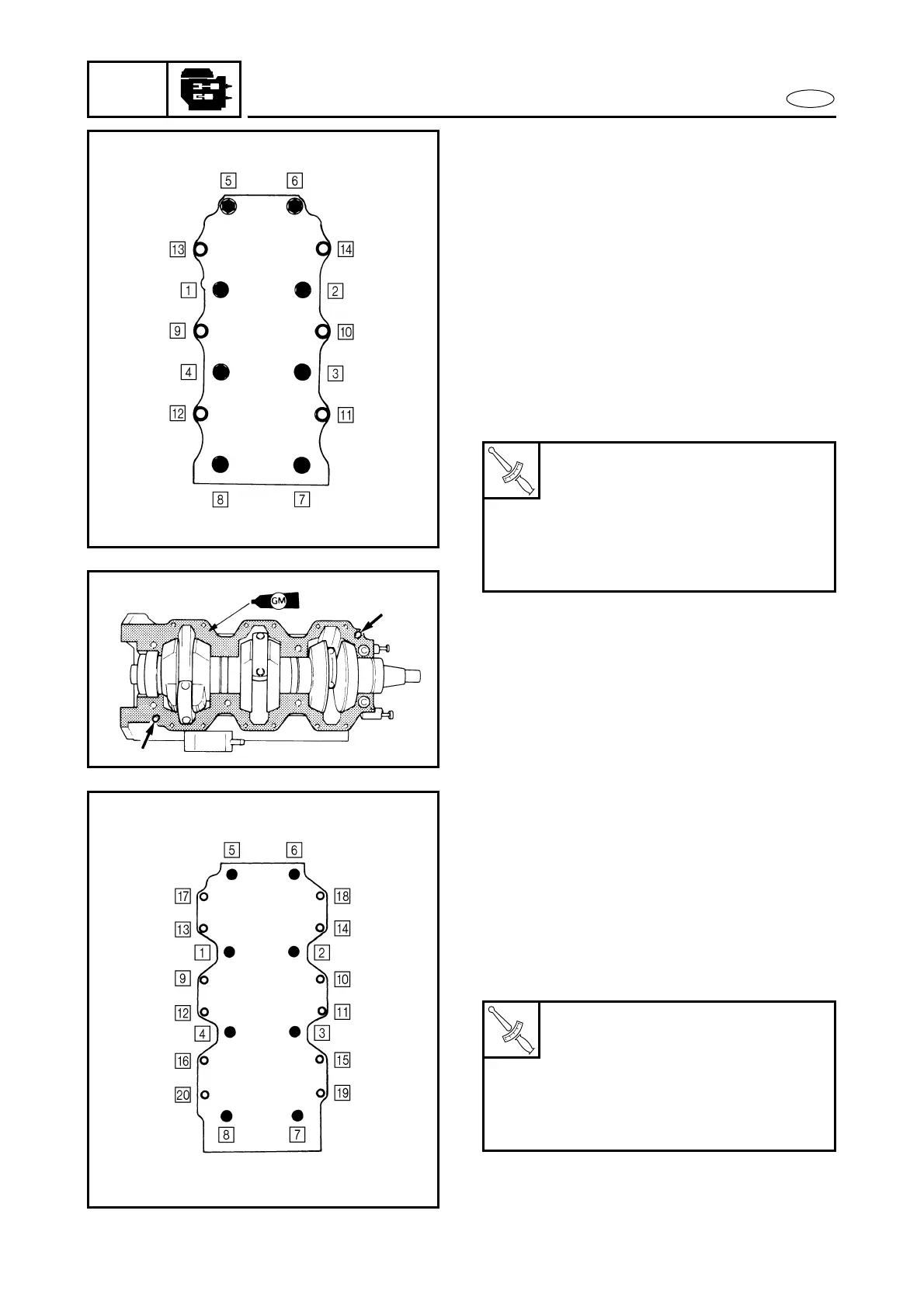

5. Match the cylinder-block and tighten

the bolts to the specified torque in

sequence and in two steps.

6. Check that the crankshaft turns

smoothly.

G74002-0*

CRANK CYLINDER ASSEMBLY

(75, 80, 90 hp)

1. Align each locating-pin of the bearings

and labyrinth-seals with each cut on the

cylinder-block. Then, fit the crank

assembly in place.

2. Film-coat the cylinder-block mating sur-

face with Gasket Maker or equivalent.

3. Install the dowel-pins.

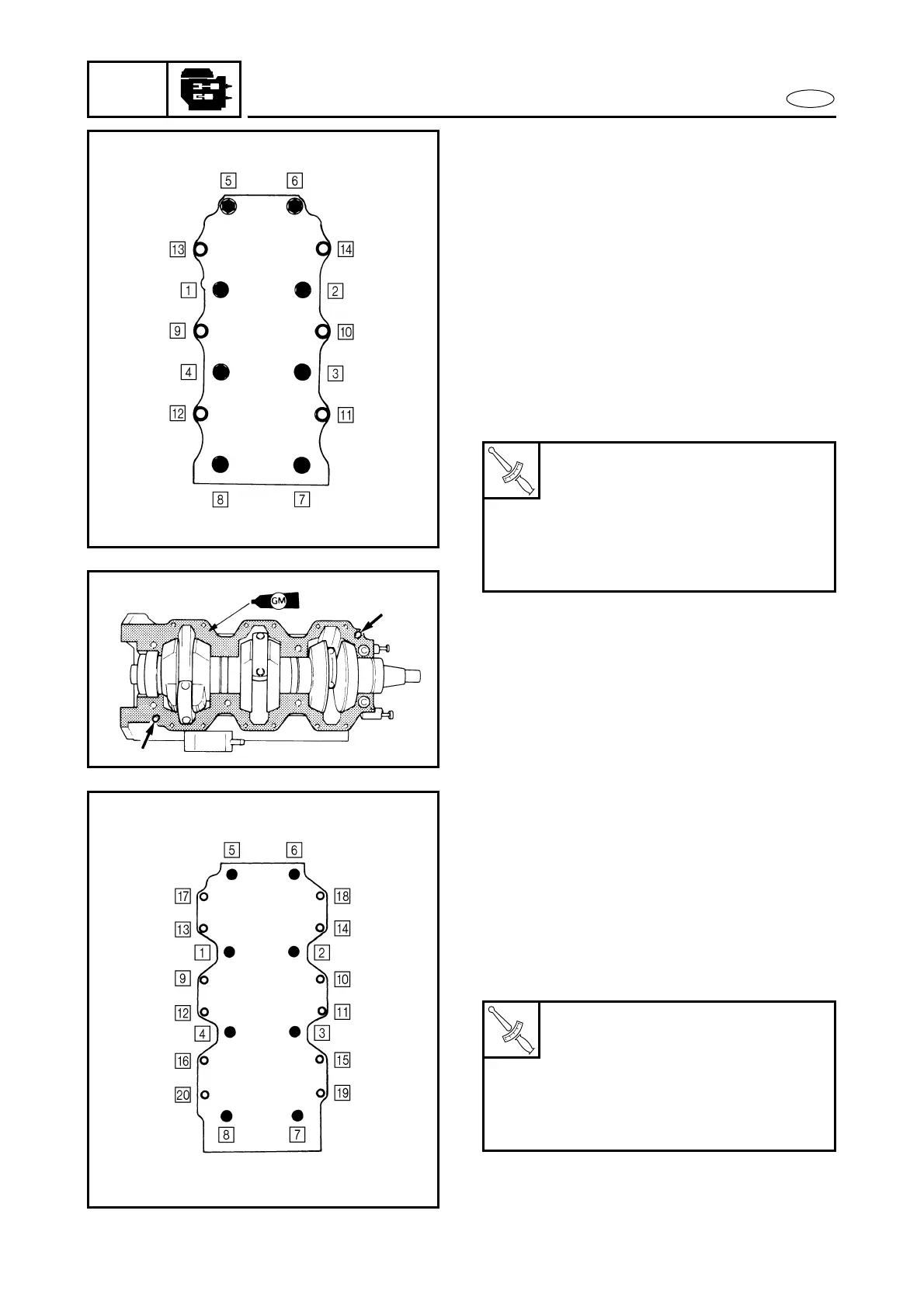

4. Match the cylinder-block and tighten

the bolts to the specified torque in

sequence and in two steps.

5. Check that the crankshaft turns

smoothly.

T

R

.

.

Crankcase bolt (50, 60, 70 hp)

1st step:

M8: 10 Nm (1.0 m • kg, 7.2 ft • lb)

M10: 20 Nm (2.0 m • kg, 14 ft • lb)

2nd step:

M8: 20 Nm (2.0 m • kg, 14 ft • lb)

M10: 40 Nm (4.0 m • kg, 29 ft • lb)

T

R

.

.

Crankcase bolt (75, 80, 90 hp)

1st step:

M6: 4 Nm (0.4 m • kg, 2.9 ft • lb)

M10: 20 Nm (2.0 m • kg, 14 ft • lb)

2nd step:

M6: 12 Nm (1.2 m • kg, 8.7 ft • lb)

M10: 40 Nm (4.0 m • kg, 29 ft • lb)

Loading...

Loading...