8-53

8

ROBOT LANGUAGE

8-5 Sample Programs

8-5-18

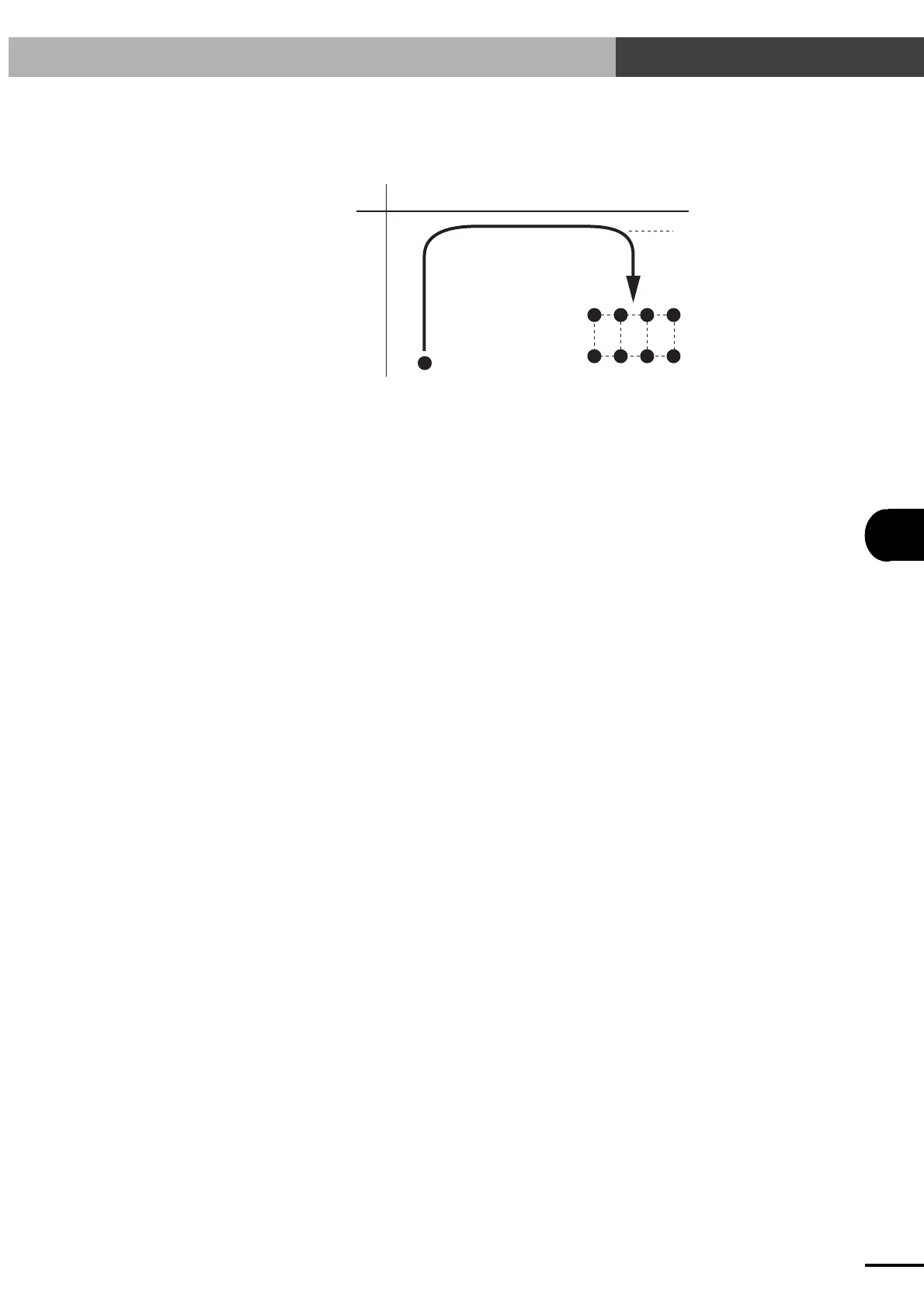

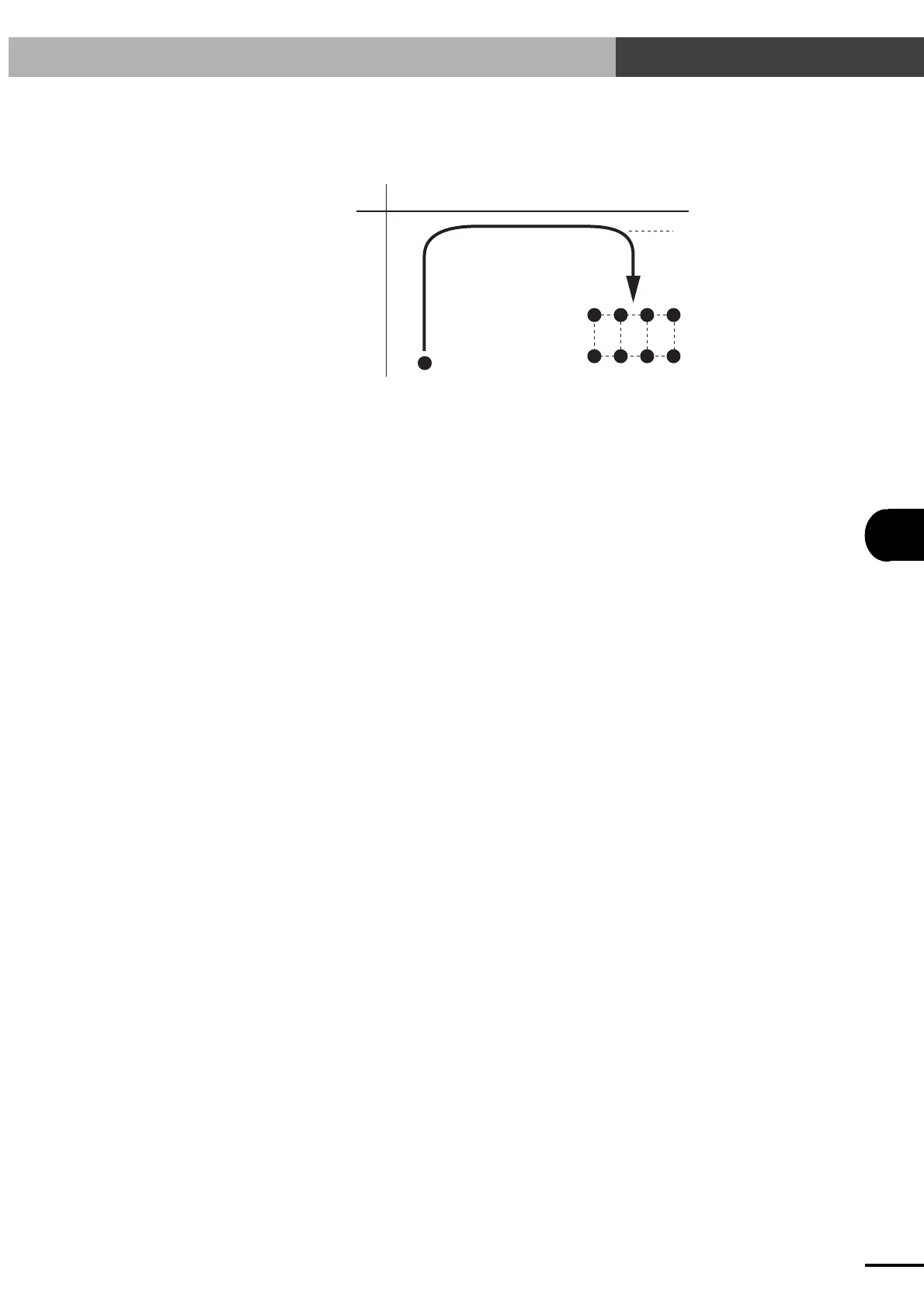

Picking up workpieces at P0 and placing them sequentially

on a 2×4 pallet

X

P0

Y=10mm

Y

Point C (=P253)

Point D (=P254)

Point A (=P251)

Point B (=P252)

■ Teaching each point of P0 and P251 to P254 should be completed beforehand in PNT

(point) mode. (Matrix is defined as pallet number 0 in this example.)

Program Comment

[NO0]

001: MAT 2, 4, 0 ; Defines 2×4 matrix as pallet number 0

002: C 1 ; Sets counter variable to 1

003: L 0 ; Label definition

004: ACHA 2, 10

; Specifies arch motion to move back Y-axis by Y=10mm

005: MOVA 0, 100 ; Moves to pick point

006: CALL 1, 1 ; PICK routine call

007: MSEL 0 ; Specifies movement matrix

008: ACHA 2, 10

;

Specifies arch motion to move back Y-axis by Y=10mm

009: MOVM C, 100 ; Moves to place point (on pallet)

010: CALL 2, 1 ; PLACE routine call

011: JMPC 1, 8 ; Jumps to L1 if counter variable is 8

012: C+ ; Counter variable increment

013: JMP 0, 0 ; Jumps to L0

014: L 1 ; Label definition

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...