7.4 Settings According to Host Controller

7-17

• B = [(Number of encoder pulses) × 4] × [motor speed]

• A = [Reference units (travel distance per load shaft revolution)] × [load shaft revolution speed]

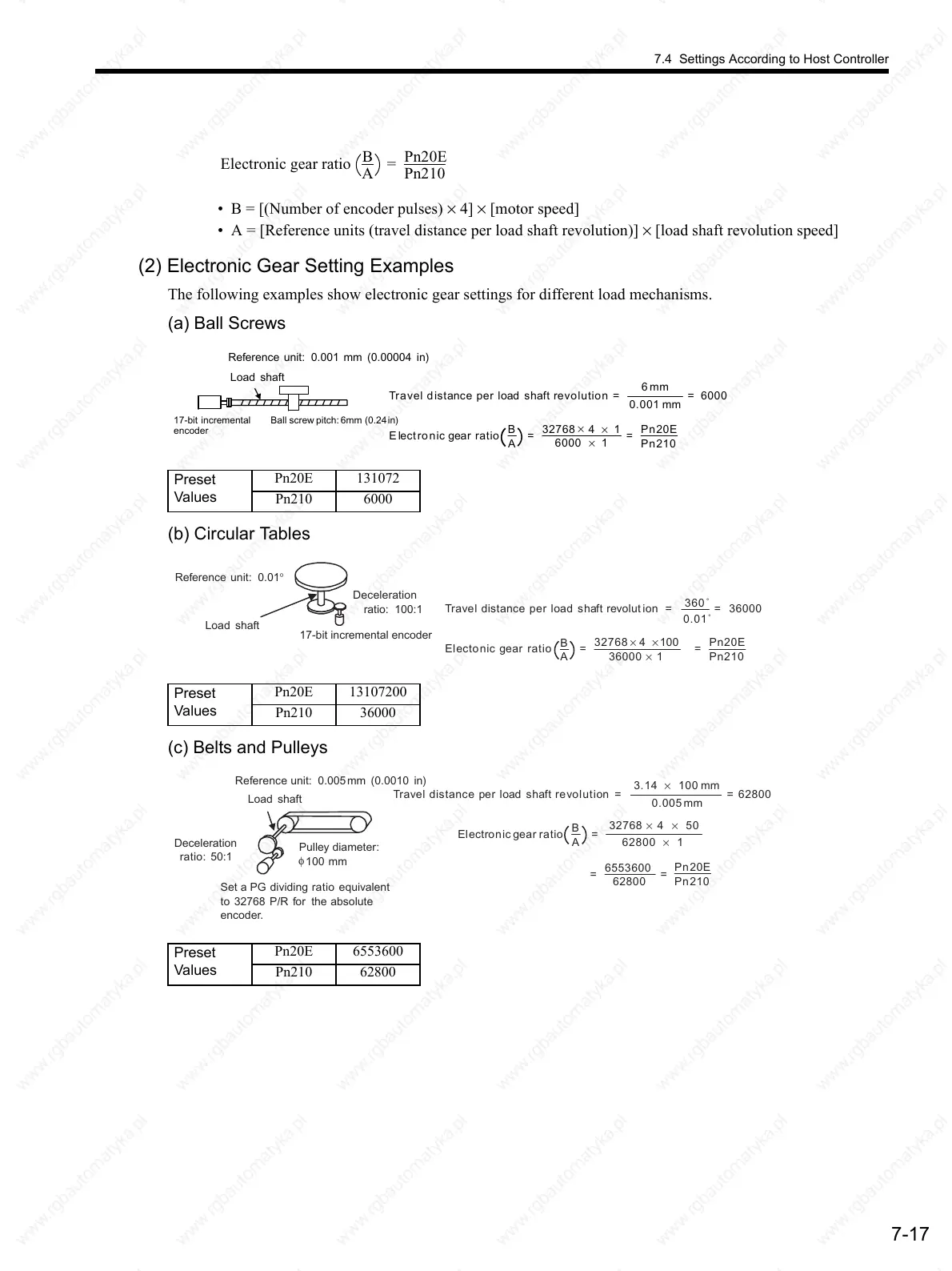

(2) Electronic Gear Setting Examples

The following examples show electronic gear settings for different load mechanisms.

(a) Ball Screws

(b) Circular Tables

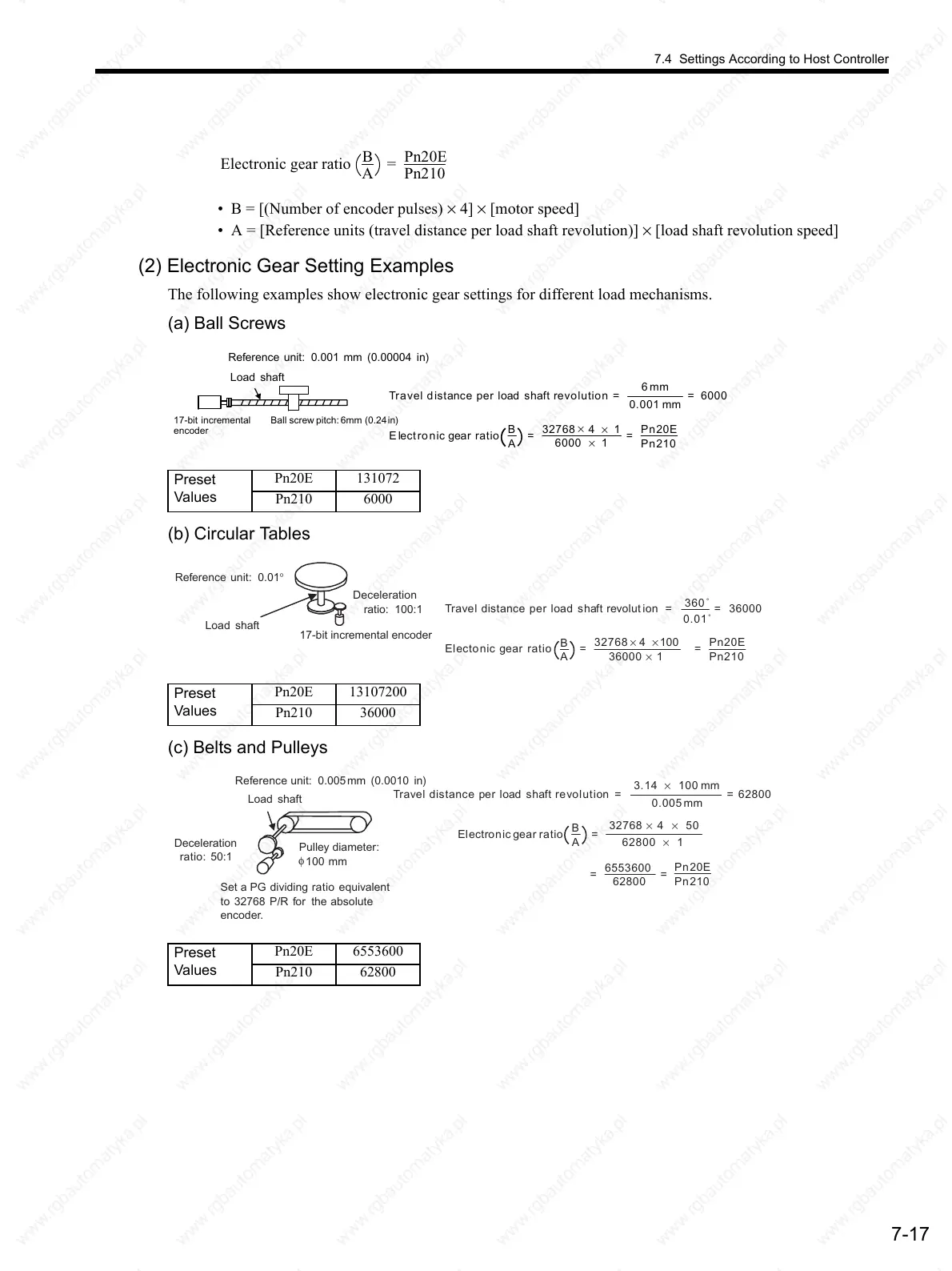

(c) Belts and Pulleys

Electronic gear ratio

B

A

=

Pn20E

Pn210

Preset

Values

Pn20E 131072

Pn210 6000

Ball screw pitch: 6mm (0.24in)17-bit incremental

encoder

Load shaft

Reference unit: 0.001 mm (0.00004 in)

Travel distance per load shaft revolution =

6mm

0.001 mm

= 6000

Electronic gear ratio

B

A

=

32768

×

4 × 1

6000 × 1

=

Pn20E

Pn210

Preset

Values

Pn20E 13107200

Pn210 36000

17-bit incremental encoder

Load shaft

Travel distance per load shaft revolut ion =

360˚

0.01˚

= 36000

Electonic gear ratio

B

A

=

32768 × 4 × 100

36000 × 1

=

Pn20E

Pn210

Reference unit: 0.01°

Deceleration

ratio: 100:1

Preset

Values

Pn20E 6553600

Pn210 62800

Load shaft

Travel distance per load shaft revolution =

3.14 × 100 mm

0.005 mm

= 62800

Electronic gear ratio

B

A

=

32768 × 4 × 50

62800 × 1

Pn20E

Pn210

Deceleration

ratio: 50:1

Reference unit: 0.005mm (0.0010 in)

Pulley diameter:

φ

100 mm

Set a PG dividing ratio equivalent

to 32768 P/R for the absolute

encoder.

==

6553600

62800

Loading...

Loading...