4.1 SERVOPACK Ratings and Specifications

4-5

4

* 1. Use the SERVOPACK within the ambient temperature range. When enclosed in a control panel, internal tem-

peratures must not exceed the ambient temperature range.

* 2. Speed regulation is defined as follows:

The motor speed may change due to voltage variations or amplifier drift and changes in processing resistance

due to temperature variation. The ratio of speed changes to the rated speed represent speed regulation due to

voltage and temperature variations.

* 3. Forward is clockwise viewed from the non-load side of the servomotor. (Counterclockwise viewed from the

load and shaft end)

* 4. The built-in open collector power supply is not electrically insulated from the control circuit in the

SERVOPACK.

* 5. The DC reactor connection terminals for power supplies designed for minimum harmonics are not included in

SERVOPACKs with capacities of 6 kW or more.

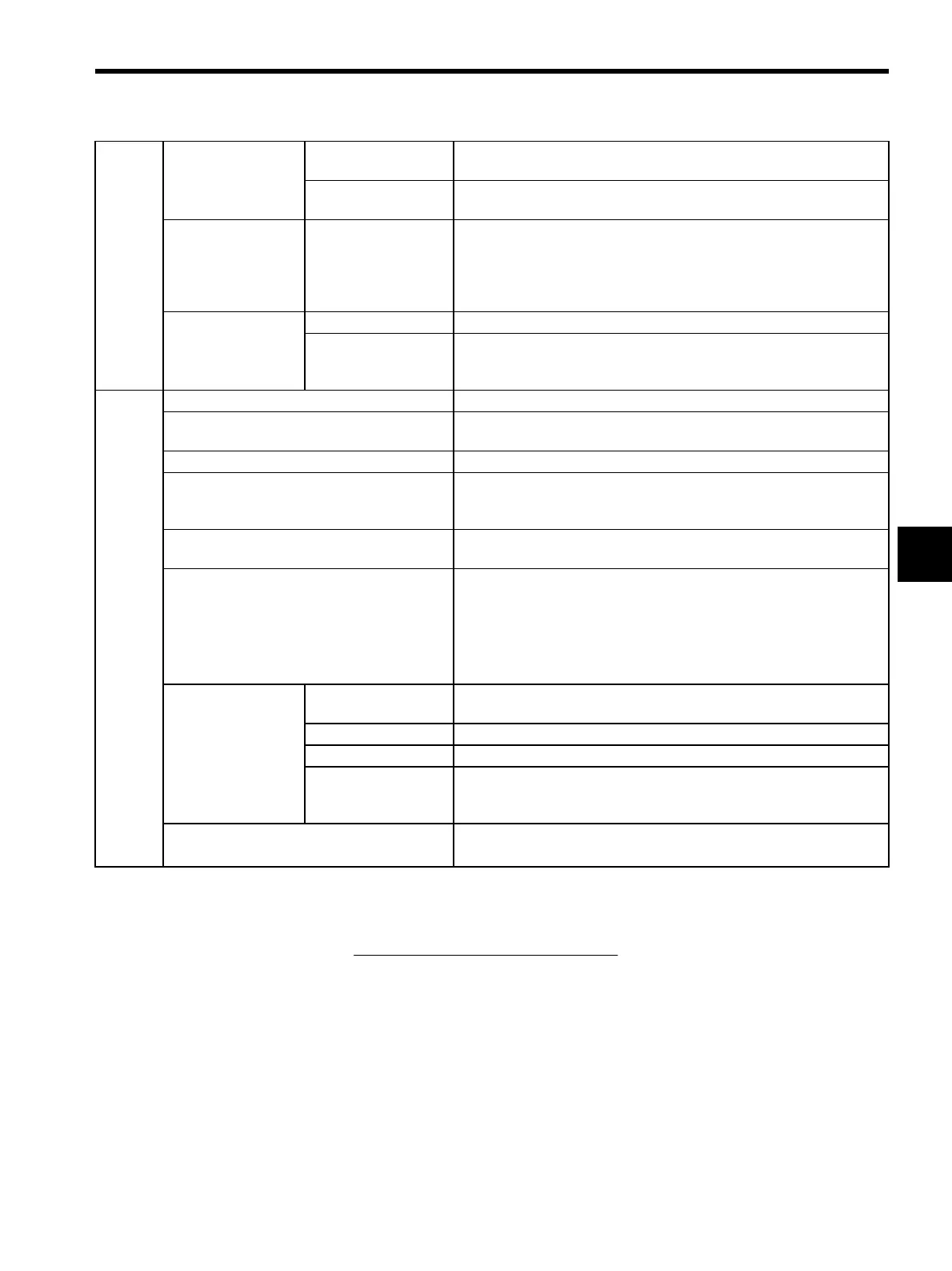

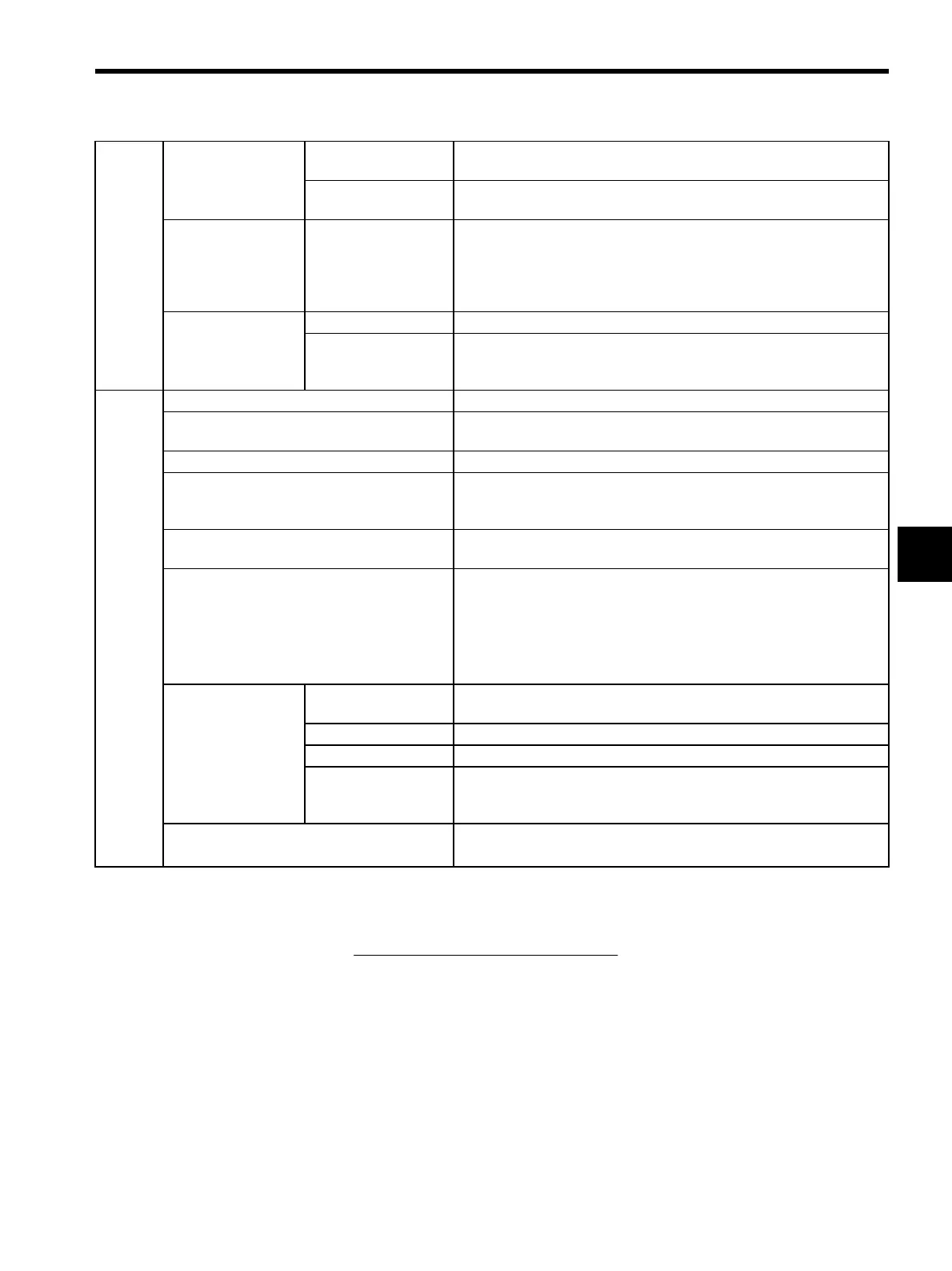

I/O

Signals

Position Output

Form

Phase-A, -B, -C line driver

Phase-S line driver (only with an absolute encoder)

Frequency Dividing

Ratio

Any

Sequence Input

Signal allocation can

be modified.

Servo ON, P control (or Control mode switching, forward/reverse motor

rotation by internal speed setting, zero clamping, reference pulse prohib-

ited), forward run prohibited (P-OT), reverse run prohibited (N-OT),

alarm reset, forward current limit, and reverse current limit (or internal

speed selection)

Sequence Output

Fixed Output Servo alarm, 3-bit alarm codes

Signal allocation can

be modified.

Positioning completed (speed coincidence), during servomotor rotation,

servo ready, during current limiting, during speed limiting, brake

released, warning, selecting three of the NEAR signals.

Internal

Func-

tions

Dynamic Brake Operated at main power OFF, servo alarm, servo OFF or overtravel.

Overtravel Stop

Dynamic brake stop at P-OT or N-OT, deceleration to a stop, or coast to a

stop

Electronic Gear 0.01 ≤ B/A ≤ 100

Protection

Overcurrent, overvoltage, low voltage, overload, regeneration error, main

circuit detection section error, heat sink overheated, no power supply,

overflow, overspeed, encoder error, overrun, CPU error, parameter error.

LED Display

Charge, Power, five 7-segment LEDs (built-in Digital Operator func-

tions)

CN5 Analog Monitoring

Analog monitor connector built in for monitoring speed, torque and other

reference signals.

Speed: 1 V/1000 min

-1

Torque: 1 V/100% of rated torque

Position error pulses: 0.05 V/1 reference units or 0.05 V/100 reference

units

Communications

Connected Devices

Digital Operator (hand-held model), RS-422A port such as for a personal

computer (RS-232C ports under certain conditions)

1:N Communications Up to N = 14 for RS-422A ports

Axis Address Setting Set with parameters.

Functions

Status display, parameter setting, monitor display, alarm trace-back dis-

play, JOG and autotuning operations, speed, torque reference signal and

other drawing functions.

Others

Reverse rotation connection, zero-point search, automatic servomotor ID,

DC reactor connection terminal for harmonic suppressions.

∗5

Speed reguration

=

No-load motor speed – Total load motor speed

Rated motor speed

× 100%

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...