AFNZPxxx– DUALACE2 NEW GENERATION – User Manual Page 55/169

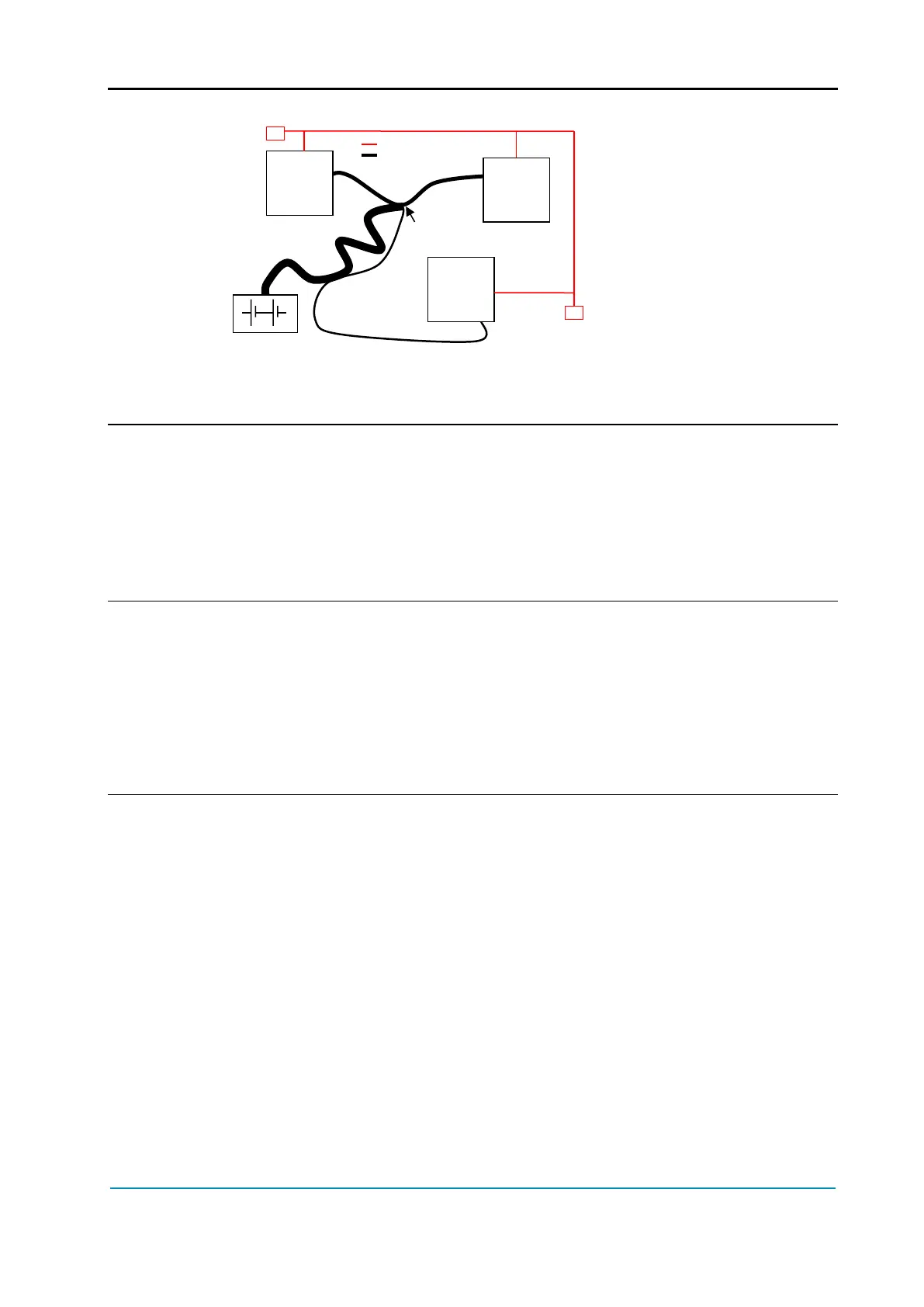

Correct Layout:

Note: Module 1 power ≈ Module 2 power > Module 3 power

In this case, the power cables of the two similar controllers must be as short as

possible. Of course also the diameter of the cables concurs in the voltage drops

described before (a greater diameter brings to a lower impedance), so in this last

example the cable between negative battery terminal and the center of the

ground connection (pointed by the arrow in the image) must be sized taking into

account both thermal and voltage drop problems and considering the current

drawn from the battery by the overall system.

The complexity of modern systems needs more and more data, signal and

information must flow from a node to another. CAN bus is the solution to different

problems that arise from this complexity.

- simple design (readily available, multi sourced components and tools)

- low costs (less and smaller cables)

- high reliability (fewer connections)

- ease of analysis (easy connection with a pc for sniffing the data being

transferred onto the bus).

5.2.5 Wirings: I/O connections

- After crimping the cable, verify that all strands are entrapped in the wire

barrel.

- Verify that all the crimped contacts are completely inserted on the connector

cavities.

- For information about pin assignment, see chapter 3.2.

- Very high currents may circulate between motor controller and battery. Even

if cables are dimensioned correctly, this may lead to a significant voltage

drop between motor controller B- terminal and negative terminal on the

battery. This means that there may be voltage differences between GND

references of different units in a control system. Therefore it is strongly

recommended to connect all wires of sensors supplied by the motor

controller directly to the intended I/O connector pins.

- Consider an alternative path for I/O cables that generates less noise (EMC).

Loading...

Loading...