Page 58/169 AFNZPxxx – DUALACE2 NEW GENERATION – User Manual

The maximum speed detectable by standard Hardware configuration can be

limited depending on the number of pulse/rev. Contact Zapi technician for

checking

It is strongly suggested, for safety reasons, to lift the wheels from the floor

and set the correct value according to the type of sensor used prior to

perform any operation with the truck.

5.2.7 Connection of Motor temperature sensor

A temperature sensor with a positive temperature coefficient embedded in the

motor winding provides a means for the motor controller to monitor motor

temperature. Motor temperature is used in the vector control algorithms, and can

also be used to protect the motor from overheating.

The motor controller can be configured to operate with different sensors such as

KTY 84, PT1000 and similar.

Installation of the motor temperature sensor is done by the motor

manufacturer. Contact the motor manufacturer to get the correct wiring. If

the temperature sensor cables are not connected with the right polarity, the

sensor readings will not be correct and overtemperature protection of the

motor will not work properly.

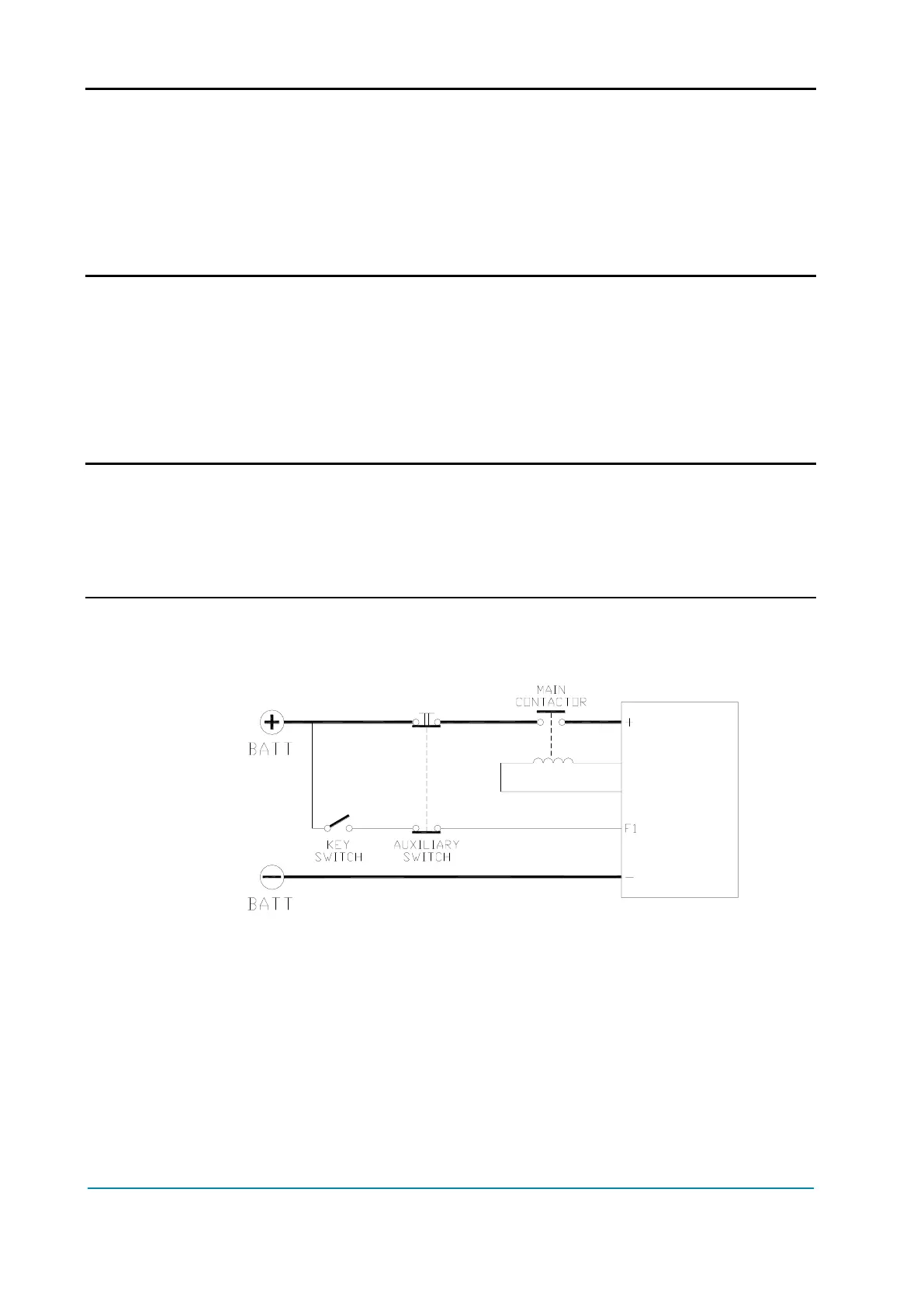

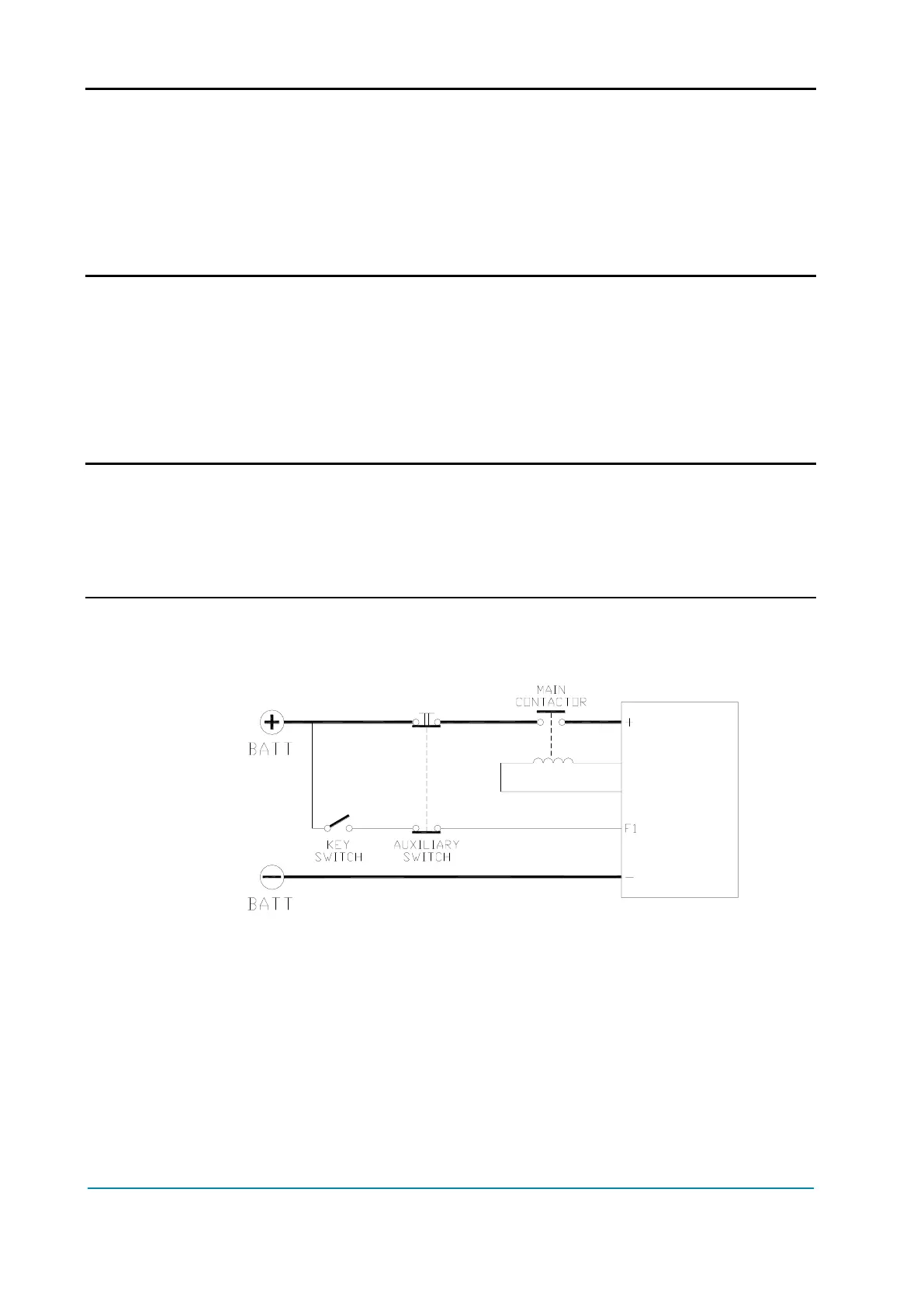

5.2.8 Connection of main contactor and key switch

Main contactor and key switch can be connected as the following figure.

CONNECTION OF MAIN CONTACTOR AND KEY SWITCH

The connection of the battery line switches must be carried out following

instructions from Zapi.

If a mechanical battery line switch is installed, it is necessary that the key

supply to the inverter is open together with power battery line; if not, the

inverter may be damaged if the switch is opened during a regenerative

braking.

An intrinsic protection is present against battery voltages above 140% of the

nominal one and against the key switching off before disconnecting the

battery power line.

Loading...

Loading...