Actual signals and parameters 253

PROTECT Detection of high outlet pressure produces an alarm on the

control panel display. The output of the PI controller is

ramped down (according to parameter 4417 PID OUT DEC

TIME) to the forced reference (set by parameter 4416

OUTLET FORCED REF). The drive reverts to the original

reference if the pressure subsequently falls below the

supervision level.

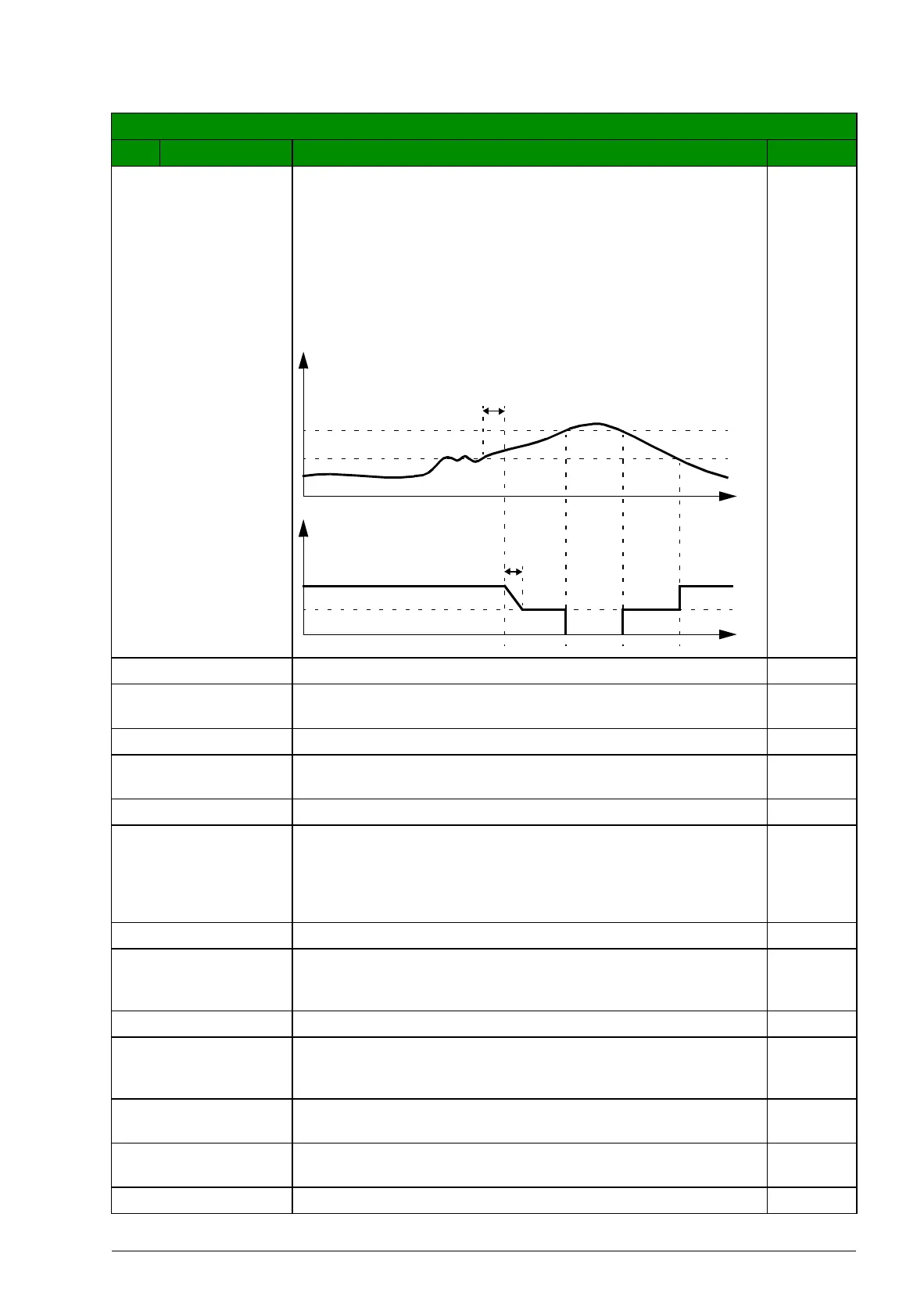

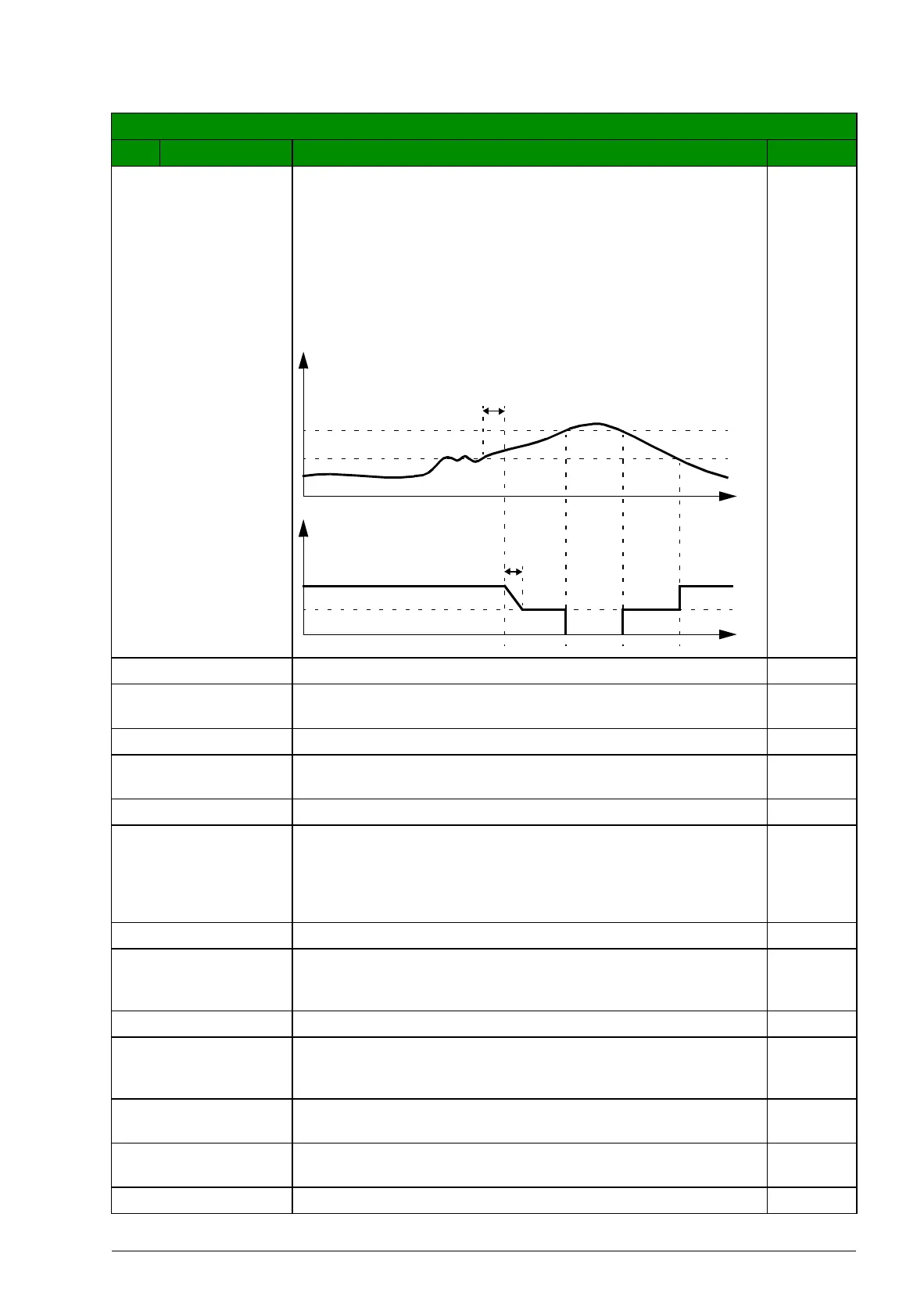

The following diagram describes the outlet pressure

supervision function.

2

FAULT Detection of high outlet pressure trips the drive on a fault. 3

4410 AI MEAS

OUTLET

Selects the analog input for pump/fan outlet pressure

supervision.

NOT SEL

NOT SEL No analog input selected 0

AI1 Pump/fan outlet pressure monitored through analog input

AI1

1

AI2 See selection AI1.2

4411 AI OUT HI

LEVEL

Sets the supervision limit for the primary outlet pressure

measurement. If the value of the selected analog input

exceeds this limit, the action defined by parameter 4409

OUTLET PROT CTRL is taken after a delay set with

parameter 4415 OUTLET CTRL DLY expires.

100.00%

0.00…100.00% Supervision level 1 = 0.01%

4412 VERY HIGH

CTRL

Enables, and selects the mode of, the secondary outlet

pressure supervision function. The function uses the analog

input selected by parameter 4410 AI MEAS OUTLET.

NOT SEL

NOT SEL Secondary outlet pressure monitoring not used 0

STOP Detection of very high outlet pressure stops the drive. The

drive starts again if the pressure falls below the supervision

level.

1

FAULT Detection of very high outlet pressure trips the drive on a

fault.

2

4413 AI OUT VERY

HIGH

Supervision level for secondary outlet pressure monitoring

function. See parameter 4409 OUTLET PROT CTRL.

100.00%

0.00…100.00% Supervision level 1 = 0.01%

All parameters

No. Name/Value Description Def/FbEq

Measured outlet

pressure

4415

4413

4411

4417

4416

t

t

EXT2 reference

(from PID1OUT)

Loading...

Loading...