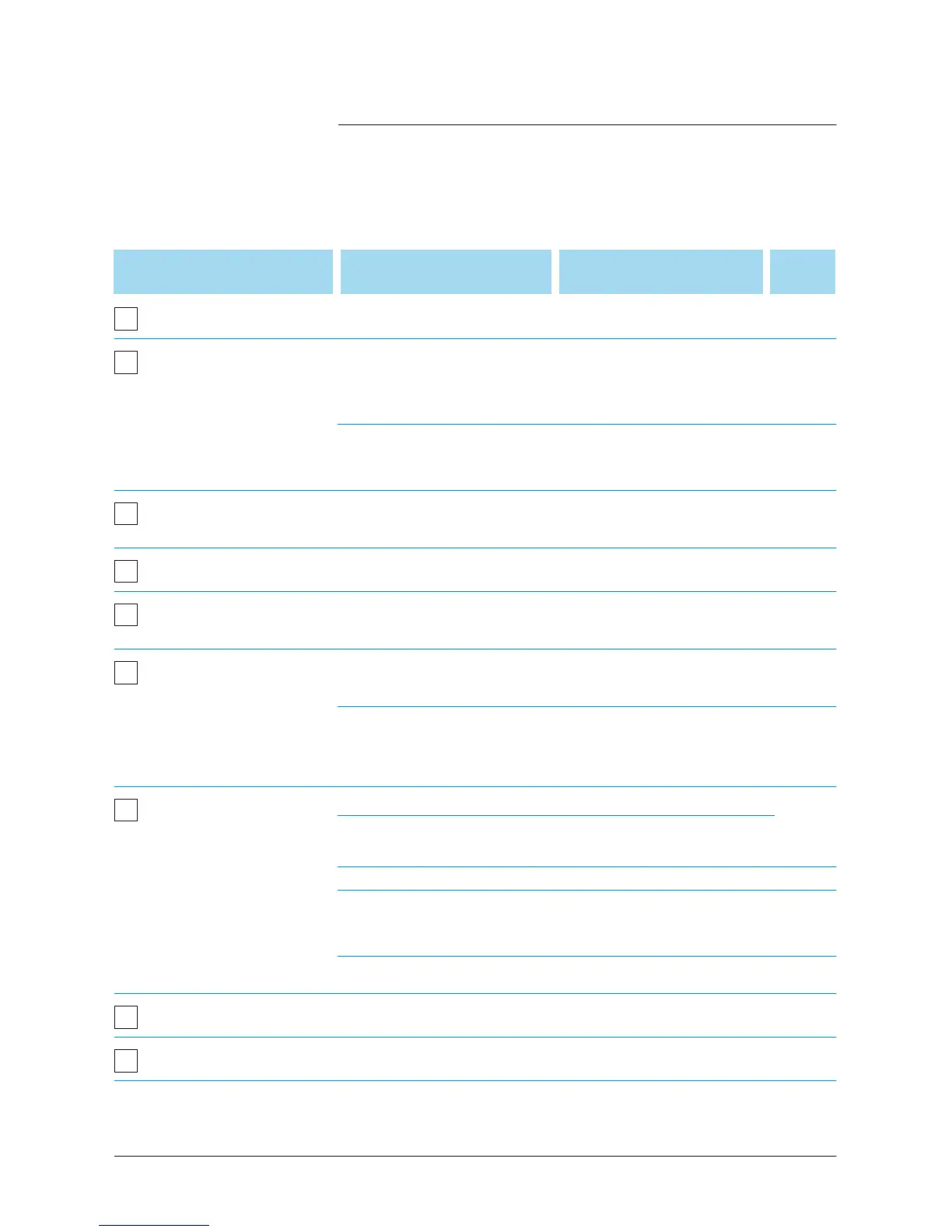

No test

cycle

start at the test

chamber closing

Sensor disconnected: sensor light

of

f

n Check the sensor connection to the -

test chamber and the

board

High helium background signal

Ambient

air helium

contamination

(background OK when

leak

detector

placed in another

room

or

environment,

free of

helium

contamination)

Internal

LDS

plastic tube disconnected

(background

decreases

very

slowly

when sniffer probe tip is blocked

with

a

finger)

Helium signal unstable

Ambient

source of

helium

contamination

50

Inconsistent

Helium signal Fine signal

adjustment required

51

Temperature too low/ high

Ambient temperature

sensor

52

Pump failure

Overheating

n Clean ambient

air

n Repair

LDS

probe tube (tightness

of

connectors) or change

LDS

probe

n Check possible

sources

of

helium

emission in the

surroundings

Eliminate or isolate

it

n Make an external

calibration

in

sniffing mode

n Make sure the leak detector is

used

within

ambient

temperature

tolerance

n Check the connections : unplug

and

plug the cables on the P0326

board

and the

pump

n If the pump isn’

t

locked at

starting,

the orange led on the P0326

lights

on after the simultaneous

lighting

of

the 3 leds during 3-4 seconds.

Recondition the pump or replace

it.

-

G 400

-

C

303

A 800

-

E

740/E

747

53

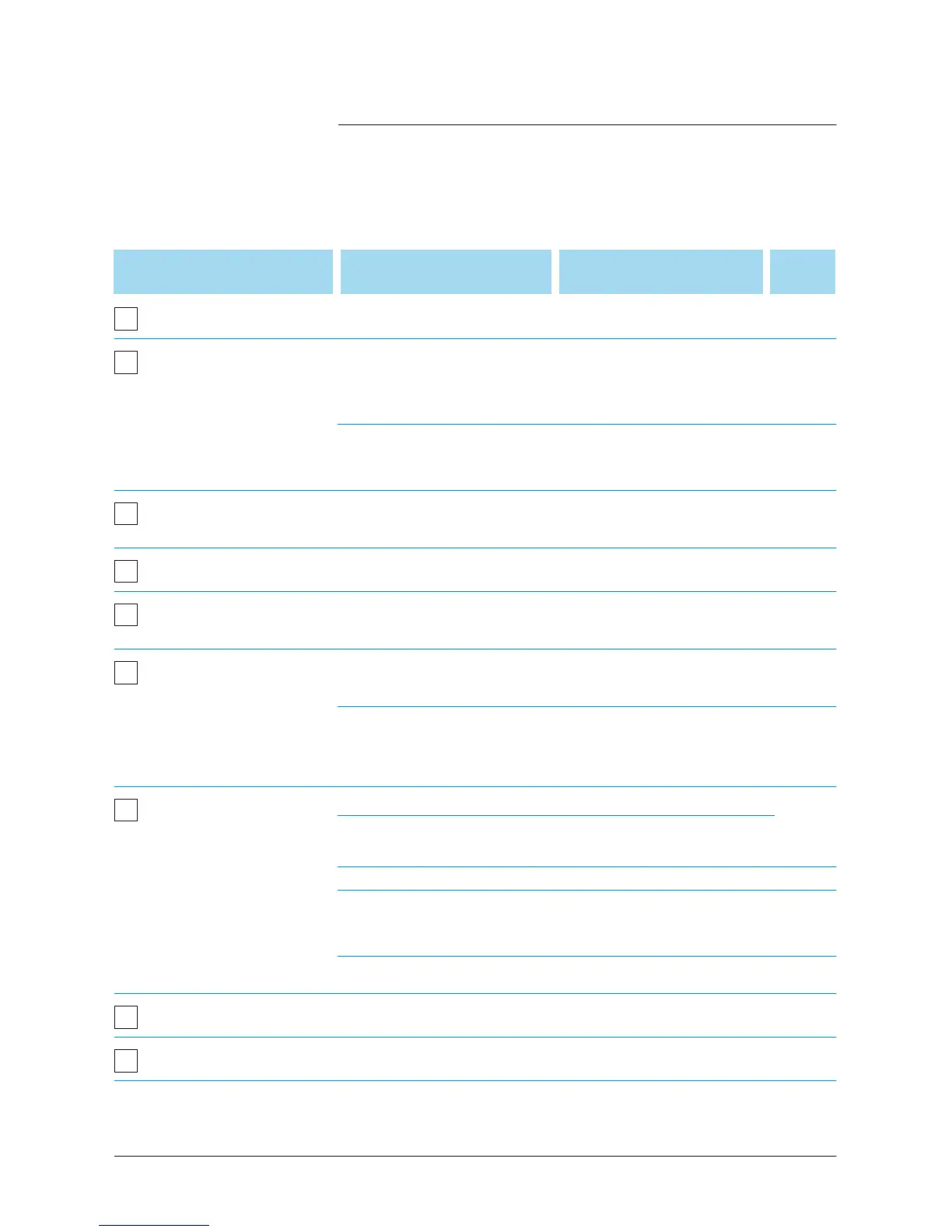

Pump speed P0326 switch is in

running

in n -

No noise from the rotary vane

pump

Abnormal noise from the rotary

vane pump

The exhaust pressure of the

pump

is not correct (lower or equal to 5

mbar )

The exhaust valve has not

opened

Leaks inside the leak

detector

Greasing of the pump ball bearings

to

be

performed

Rotary vane pump power supply

not

connected

Oil

temperature

lower than 10°C

n Check the

pump

n Check the gross leak valve

n Check the tightness of

the

canalizations, valves, pumps

and

cell (alcohol test or use of

another

detector)

n Regrease the pump ball

bearings

n Connect the rotary vane

pump

power supply

connector

n Heat the pump body

to

approximately

18°C

E

740

-

E

740

-

-

5/6

Loading...

Loading...