C-2 RJ45 DSI Splitter Cable

DSI Cable Accessories

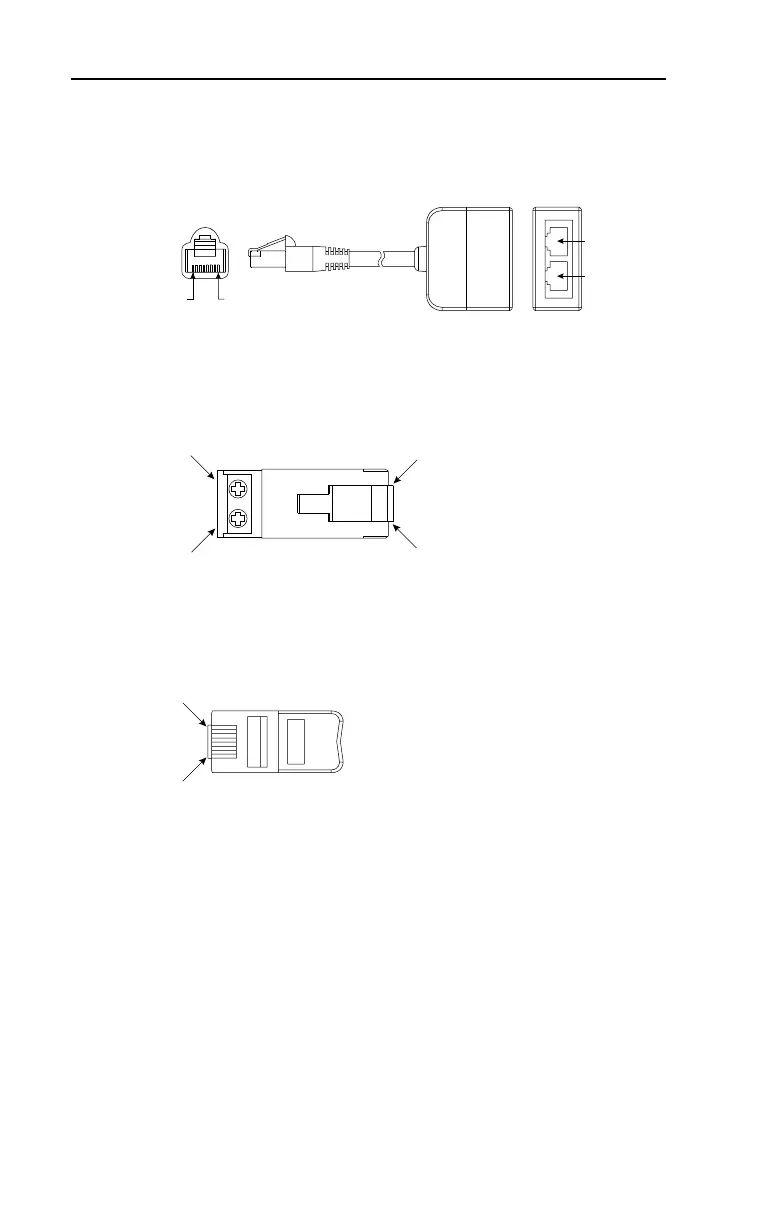

RJ45 Splitter Cable

– Catalog Number: AK-U0-RJ45-SC1

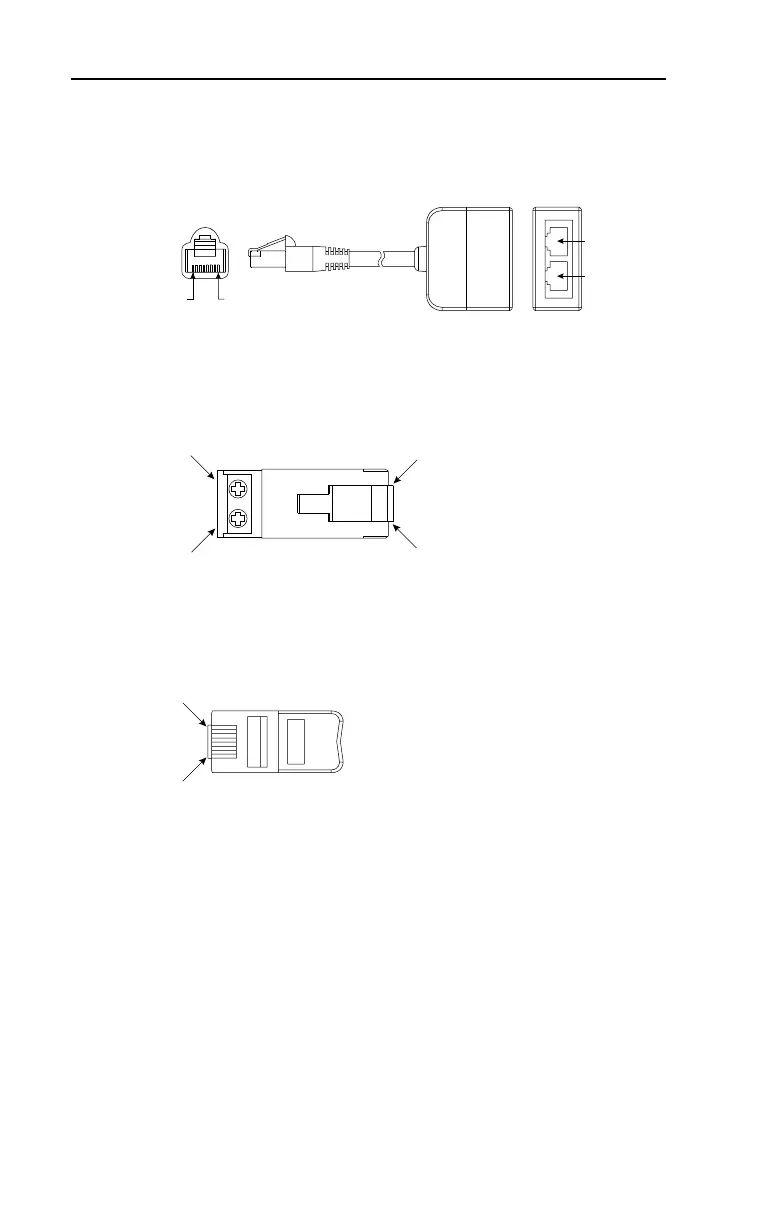

RJ45 Two-Position Terminal Block Adapter –

Catalog Number: AK-U0-RJ45-TB2P

RJ45 Adapter with Integrated Termination Resistor –

Catalog Number: AK-U0-RJ45-TR1

Slave Port

Master Port

PIN

PIN 1

M

S

TB2

(PIN 5)

TB1

(PIN 4)

PIN 8

PIN 1

PIN 8

PIN 1

Loading...

Loading...