Installation/Wiring 1-15

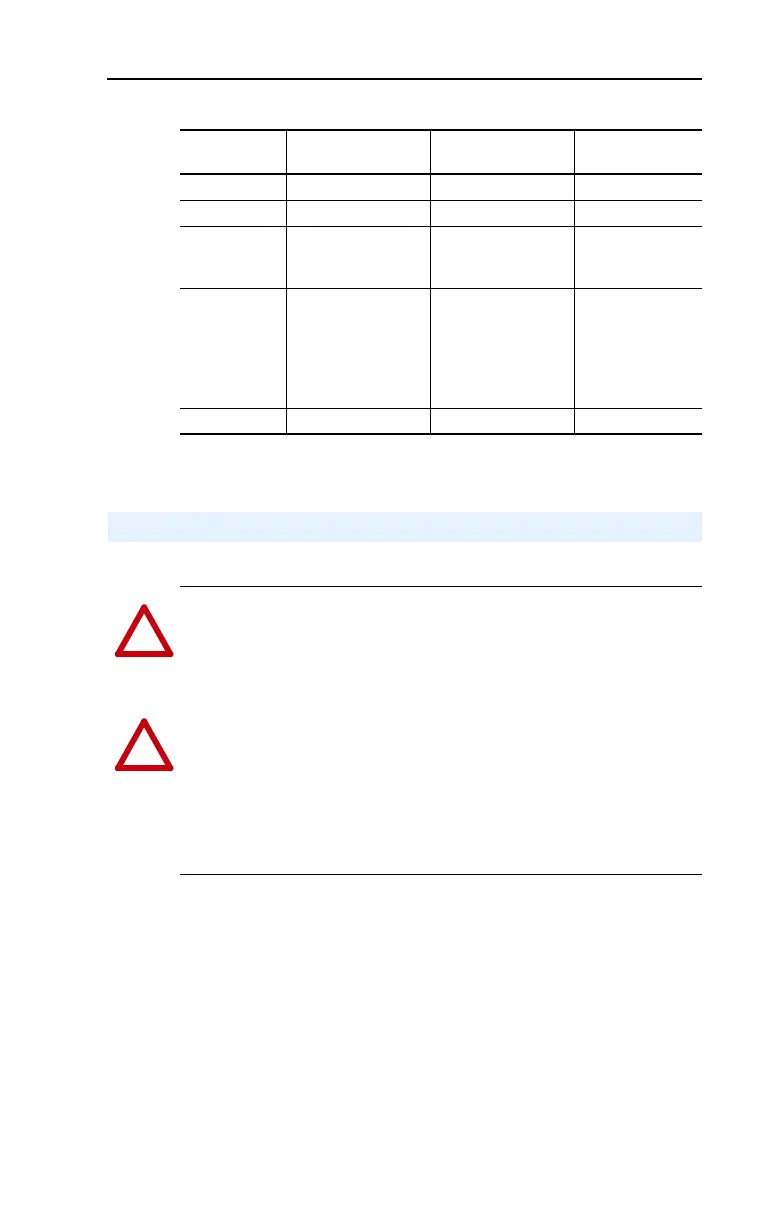

Table 1.D Power Terminal Block Specifications

Motor Start/Stop Precautions

Frame Maximum Wire Size

(1)

(1)

Maximum/minimum sizes that the terminal block will accept - these are not

recommendations. If national or local codes require sizes outside this range, lugs may

be used.

Minimum Wire Size

(1)

Recommended

Torque

C 8.4 mm

2

(8 AWG) 1.3 mm

2

(16 AWG) 2.9 N-m (26 lb.-in.)

D 33.6 mm

2

(2 AWG) 8.4 mm

2

(8 AWG) 5.1 N-m (45 lb.-in.)

E 480V

37-45 kW

(50-60 HP)

33.6 mm

2

(2 AWG) 3.5 mm

2

(12 AWG) 5.6 N-m (49.5 lb.-in.)

E 240V

30-37 kW

(40-50 HP)

480V

55-75 kW

(75-100 HP)

107.2 mm

2

(4/0 AWG) 53.5 mm

2

(1/0 AWG) 19.5 N-m (173 lb.-in.)

F 152.5 mm

2

(300 MCM) 85.0 mm

2

(3/0 AWG) 19.5 N-m (173 lb.-in.)

I/O Wiring Recommendations

!

ATTENTION: A contactor or other device that routinely disconnects

and reapplies the AC line to the drive to start and stop the motor can

cause drive hardware damage. The drive is designed to use control input

signals that will start and stop the motor. If used, the input device must

not exceed one operation per minute or drive damage can occur.

!

ATTENTION: The drive start/stop control circuitry includes

solid-state components. If hazards due to accidental contact with

moving machinery or unintentional flow of liquid, gas or solids exist,

an additional hardwired stop circuit may be required to remove the AC

line to the drive. When the AC line is removed, there will be a loss of

any inherent regenerative braking effect that might be present - the

motor will coast to a stop. An auxiliary braking method may be

required.

Loading...

Loading...