249ARR1575

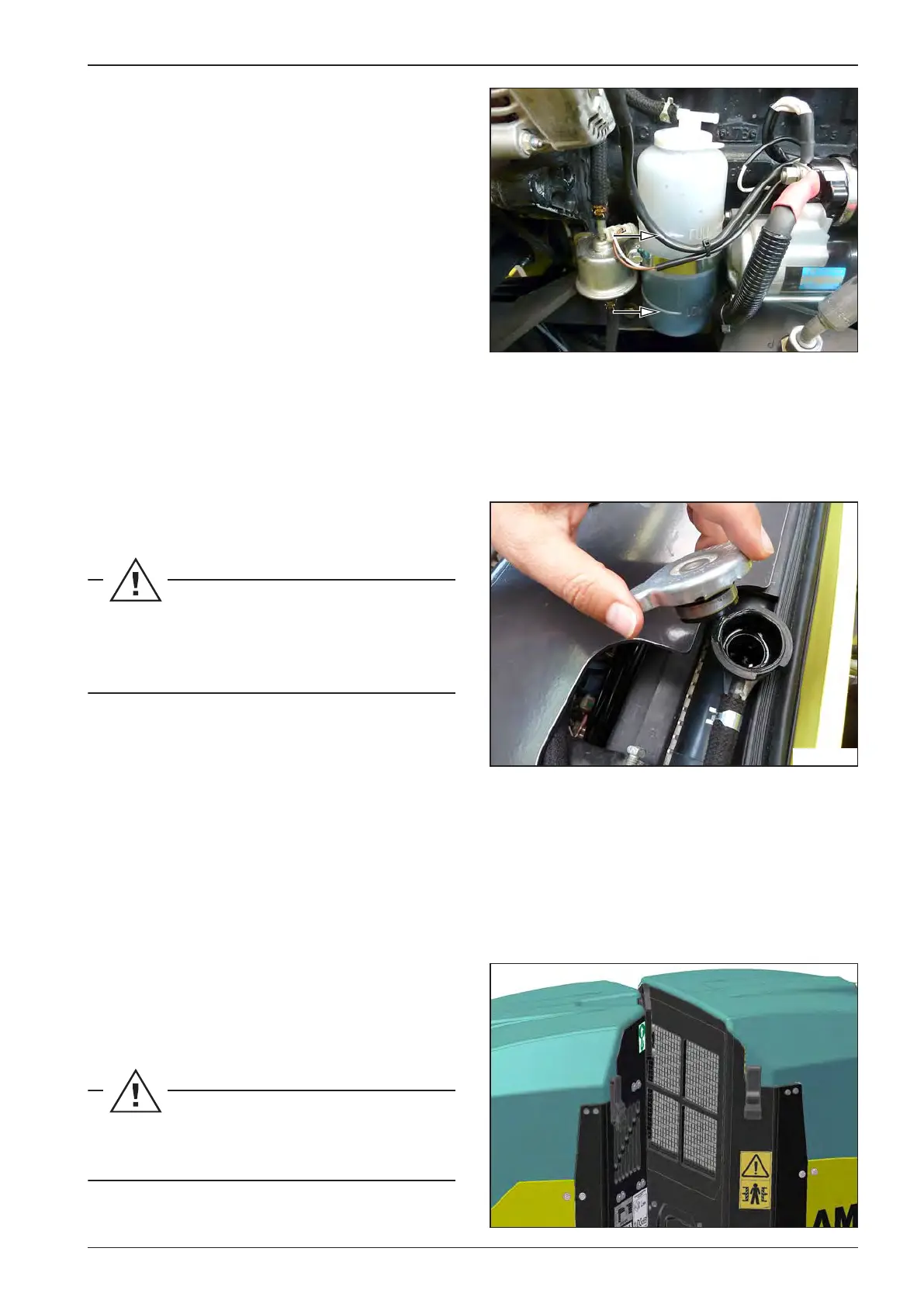

FULL

LOW

WORKSHOP MANUAL

14.4 Mechanical parts

14.4.1 Coolant and checking the coolant level

A mixture of water and an anti-freeze liquid to -25 °C has been

lled in the factory. The liquid shall be replaced with asuitable

cooler mixture at temperatures below -25 °C.

14.4.1.1 Checking the coolant level

Check the coolant level daily.

Check it at ahorizontal position of the roller and with cold en-

gine.

You can see the coolant level on the indicator situated on the

expansion vessel.

The coolant level must be between the upper mark (FULL) and

the lower mark (LOW).

Rell the coolant as required.

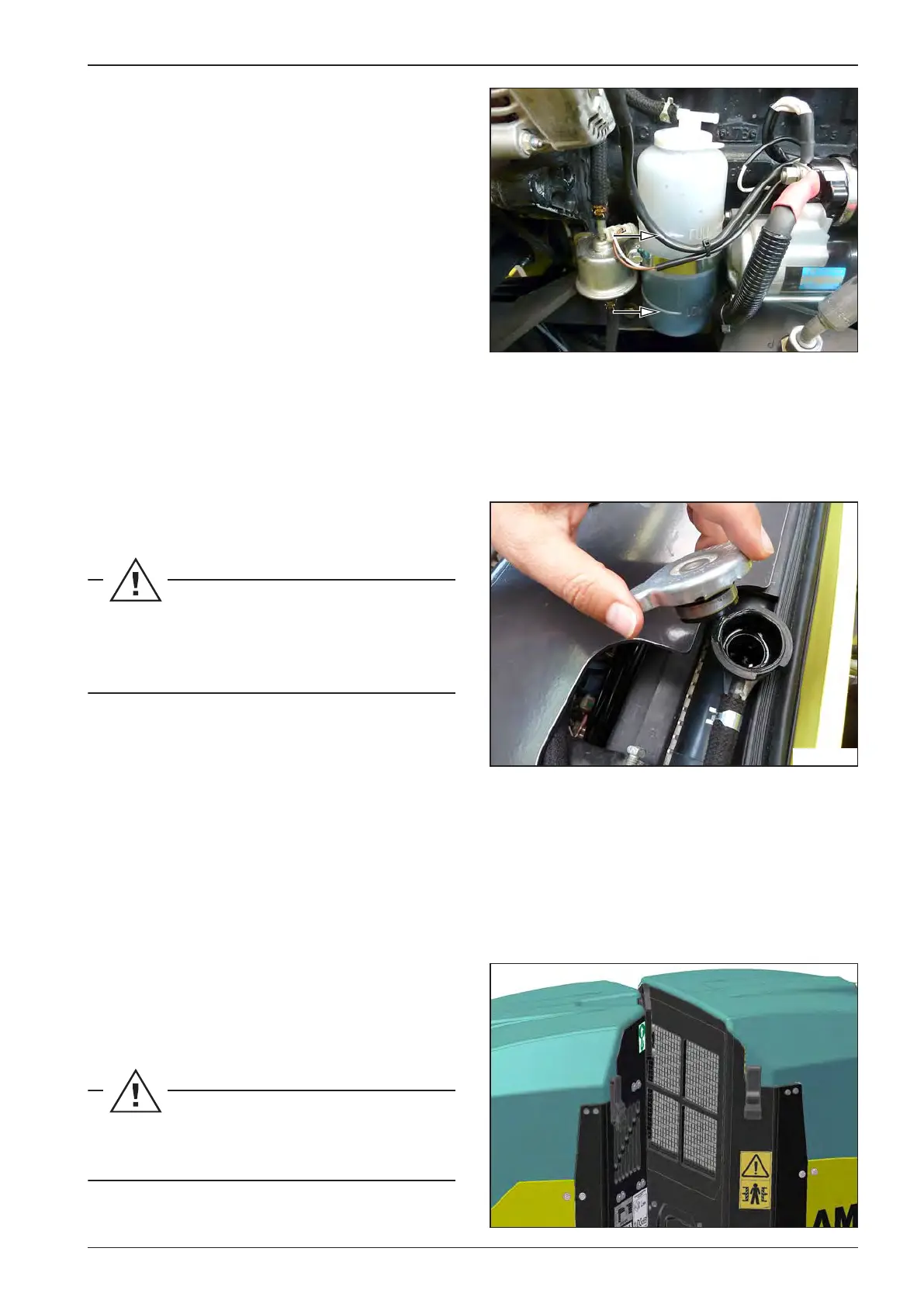

14.4.1.2 Coolant replenishment

Risk of scalding from hot coolant!

Do not open the cooler tank until the coolant and the en-

gine cool down.

Unscrew the coolant tank cap.

Fill up the cooler with acoolant with an anti-freeze liquid.

14.4.1.3 Cooler cleaning

Check that the cooler ns are not dirty or clogged.

Clean the ns with water or blow-clean them with compressed

air.

Never clean the cooler with high pressure (e.g. with

strong water jets).

Loading...

Loading...