291ARR1575

WORKSHOP MANUAL

18.1.5.3 Operation

• Has the manual control already been connected to the machine? -> Connect the cable to the manual control.

• Is the distance between the manual control and the machine OK? (2.5–4 m when using acable or 2.5–20 m when using remote

control)

• Is the N3 manual control battery discharged? -> Temporarily work with cable control.

Keep in mind that open anti-vandal protection may shield the infrared signal. This also applies to cable operation.

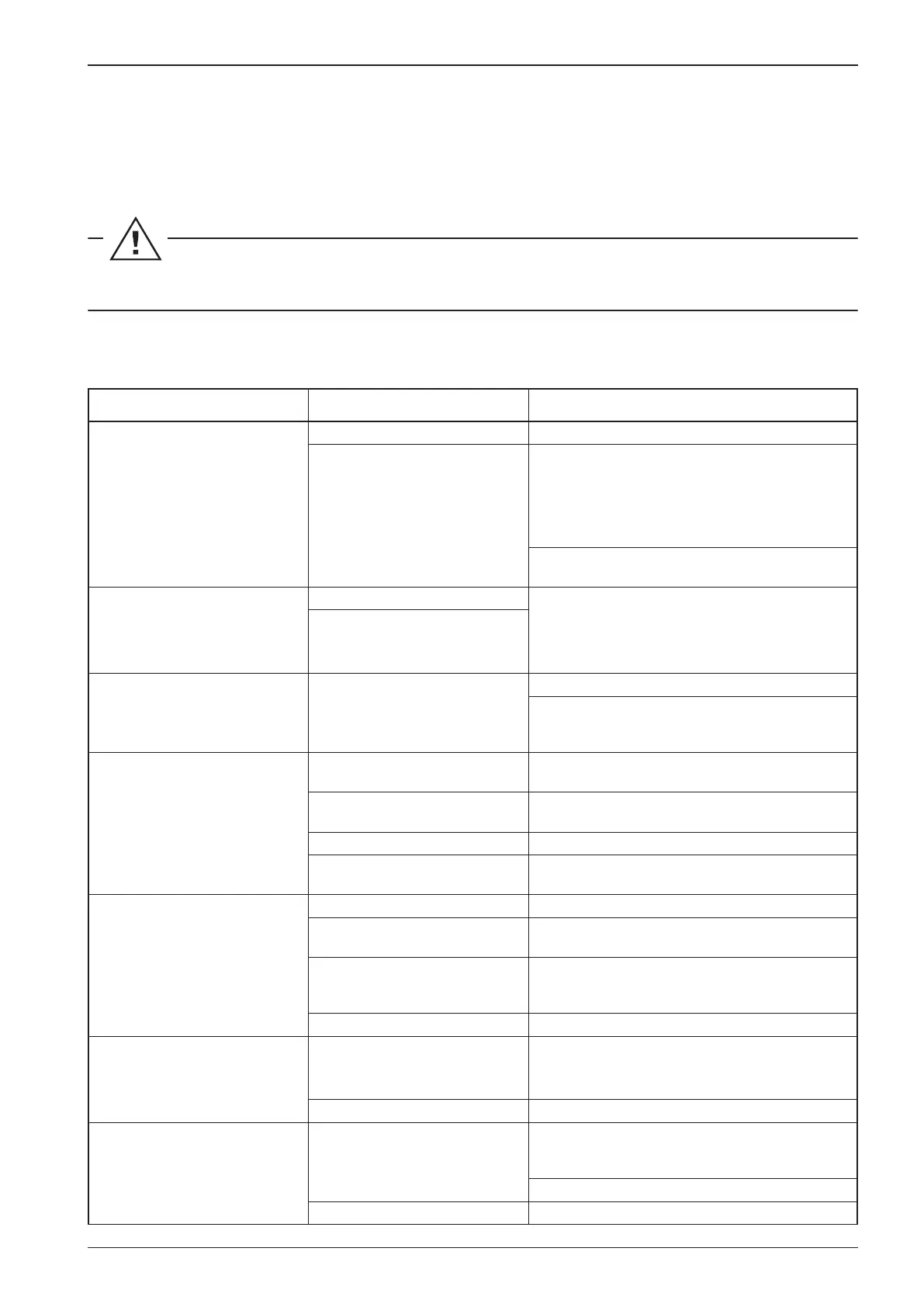

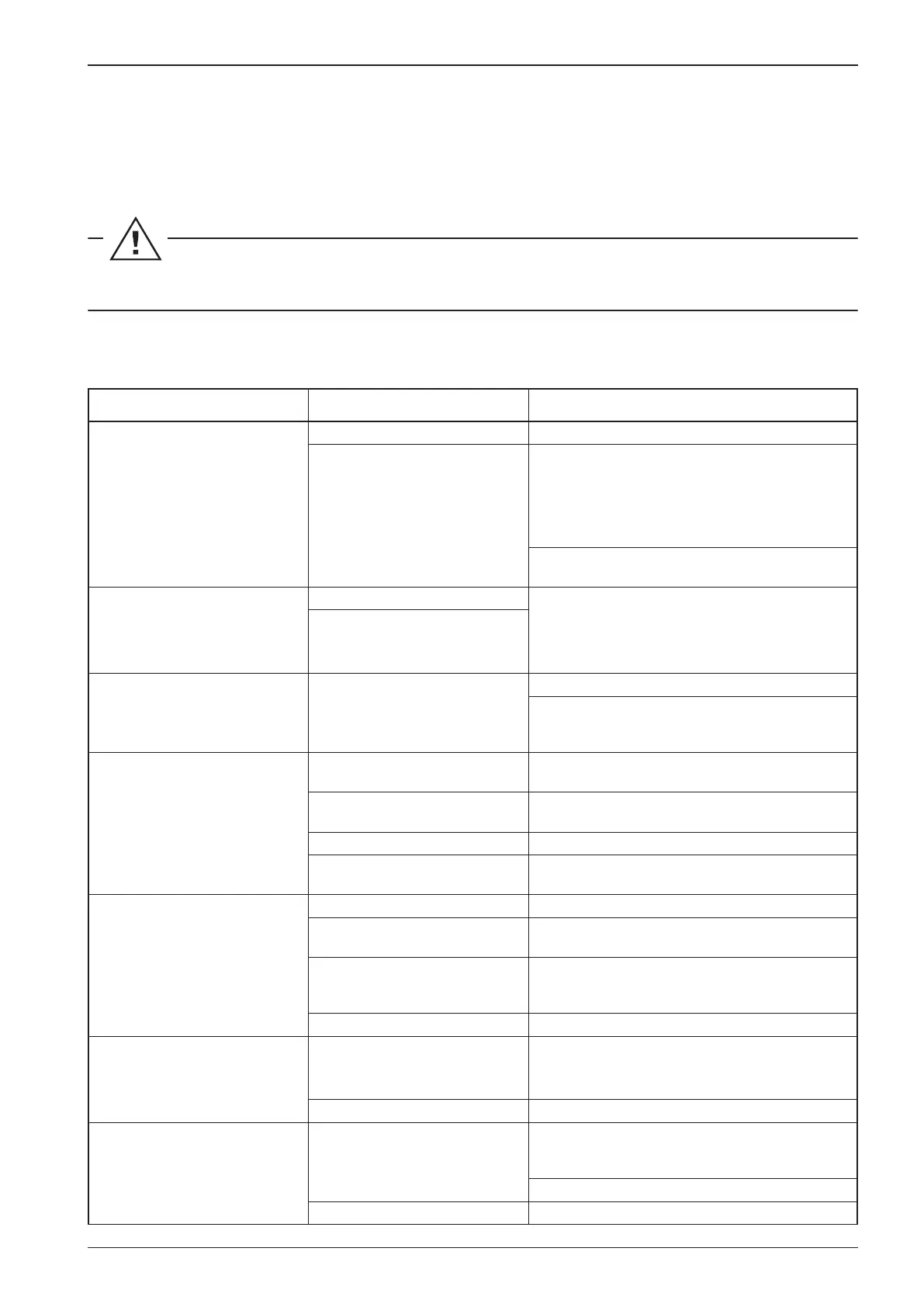

Troubleshooting, the control does not work

Defect description Probable cause Check

The control does not work at all, the

engine cannot be started even with

the ignition.

Fuses F11, F12 Are F11 and F12 OK?

N1 control unit Check the engine according to the above procedure.

Pay special attention to the signal of the D+ alternator

and the S21 engine oil pressure switch.

If the K1 relay does not switch, the problem is probably

in the N1 control unit.

Is the battery voltage OK? Battery terminals? Battery

cable on the terminals?

The machine can only be started via

ignition, otherwise nothing works

N3 infrared light emitter Check the engine according to the above procedure.

If no LEDs are ashing on the N3 manual control during

cable operation, it probably must be replaced.

Check the cabling.Infrared sensors P1, P2

The machine only works when used

with acable.

N3 infrared light emitter Check the engine according to the above procedure.

If the red LED is always on the N3 manual control with-

out a cable when any function is performed or if no

LED is on without acable, the battery may be defective.

The diesel engine suddenly turns o

during operation.

N1 control unit Watch also the display unit. The inclination sensor may

not be activated correctly.

S22 water temperature switch At normal operating temperature, the switch must be

open.

S21 engine oil pressure switch When the engine is running, the switch must be open.

G1 alternator When the engine is running, the connection must be

D+=12 V.

The machine is not moving (noth-

ing is happening)

N3 manual control Is the green LED ashing when you press the switch?

N1 control unit Is the H6 warning indicator lamp illuminated on the

display unit?

Y3 travel pump Are the connectors connected? Are the magnetic coil

and valves OK? Is the supply pressure OK? Is the servo

block OK?

Y9 brake valve Is the connector connected?

The machine is not moving (moves

against the brake)

Y9 brake valve Is the connector connected?

Activate the magnetic valve. Does the brake release? Is

the supply pressure OK?

N1 control unit Does Y9 activate?

The machine moves only forward S24 contactless switch If the machine is equipped with asafety bar, check that

the magnet is positioned correctly on the bar. If the

safety bar is not activated, the switch must be closed.

Otherwise, check the jumping in the S24 place.

Travel pump Y3, Y4 Are the connectors connected?

Loading...

Loading...