36 ARR1575

1

1

5 Frame

5.4 Mechanical parts

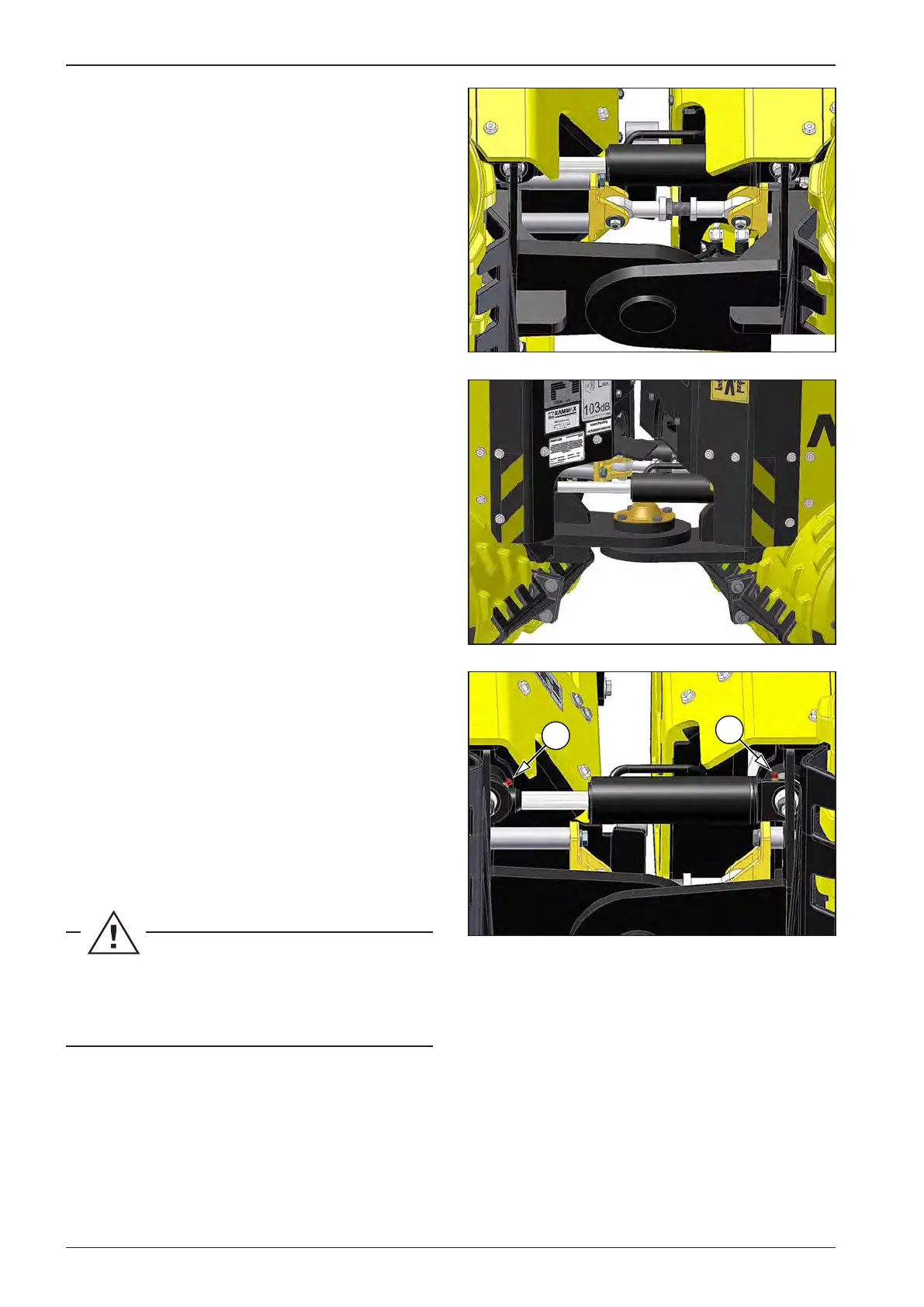

5.4.1 Swinging support, replacement of the

joint head

Check the swinging support once a year for potential occur-

rence of inadequate clearance.

Hang the roller on acrane (central suspension).

The clearance can be checked when lifting and lowering the

roller (visual check).

5.4.2 Replacement of swinging joint bearing

Check the swinging joint once ayear for potential occurrence of

inadequate clearance. If axial clearance exceeds 4 mm, the joint

must be replaced (Chapter 5.4.10).

Hang the roller on acrane (central suspension).

The clearance can be checked when lifting and lowering the

roller.

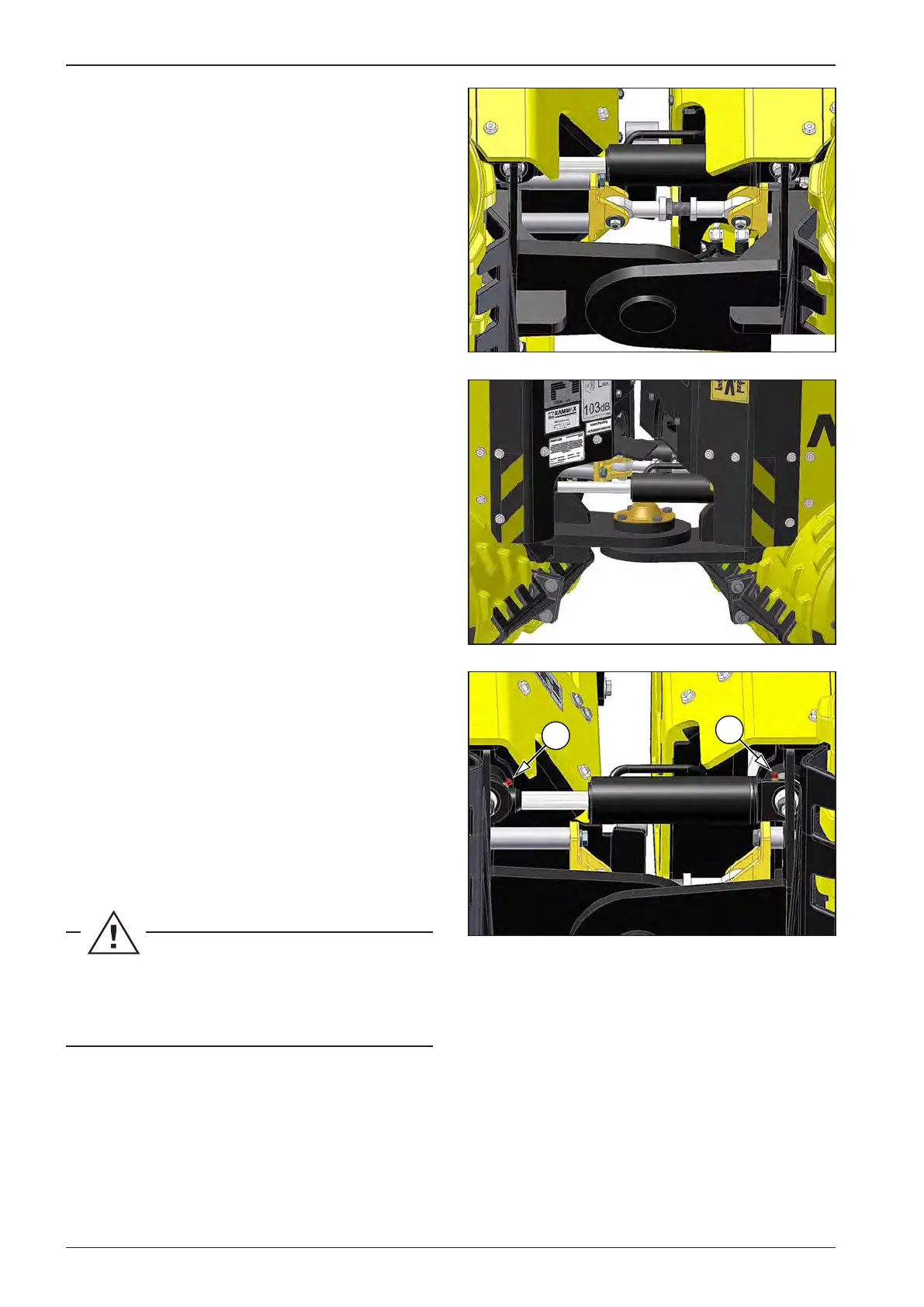

5.4.3 Steering piston, bearing lubrication

To lubricate the piston, completely turn the roller.

Move the roller from right to left briey. This will unload the

bearing.

Clean the grease nipple head (1) before lubrication.

Put agrease gun on the nipple.

Inject asucient quantity of grease so that it ows out of the

bearing.

Re-attach the protective cover.

Material damage in case of excessive wear!

Lubricate the bearing after every roller cleaning/

spraying.

Loading...

Loading...