7. ADJUSTMENTS

SL-710A

66

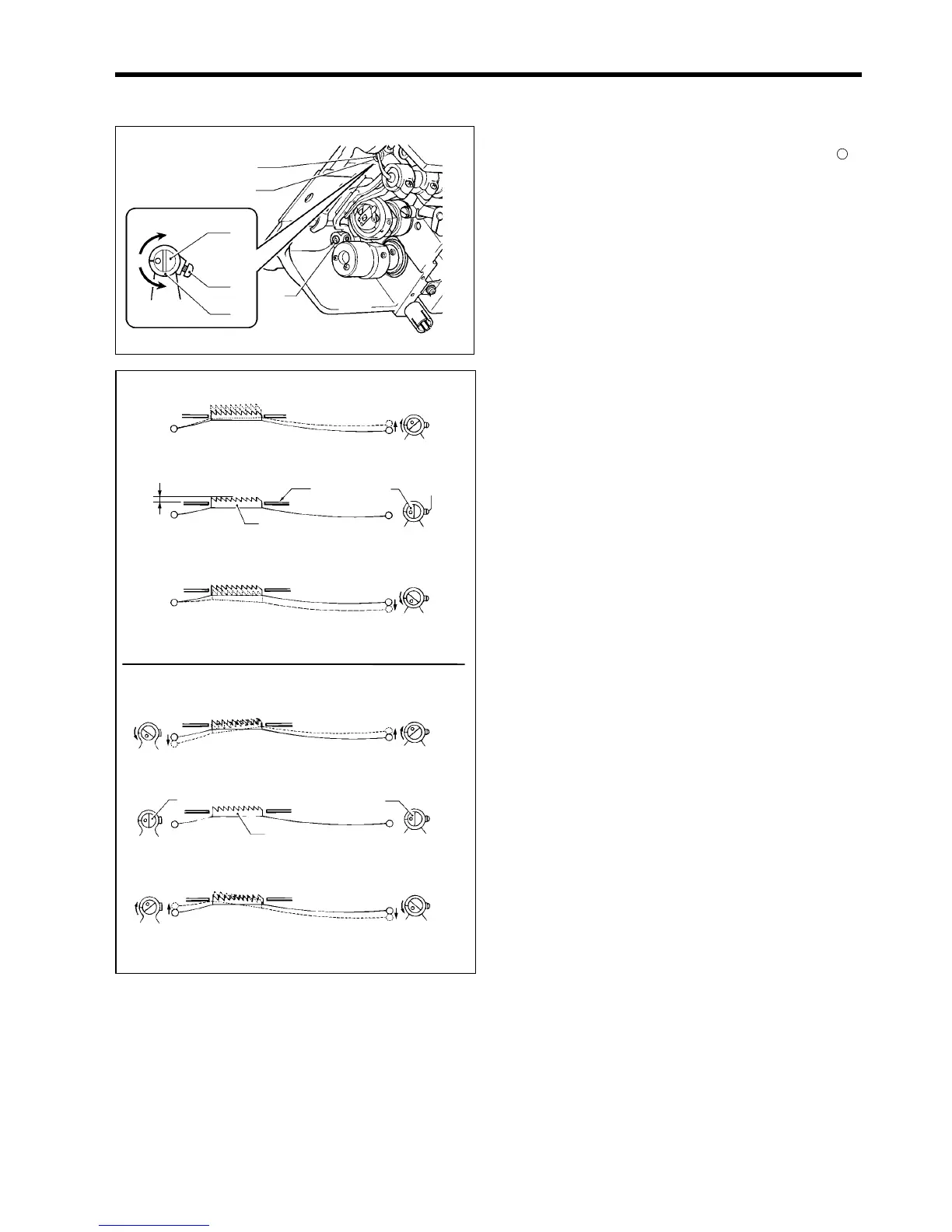

7-5. Adjusting the feed dog angle

The standard angle for the feed dog (1) when it is at its

highest position above the needle plate is when the “

”

mark (or V groove) on the shaft (2) is aligned with the feed

rocker bracket arm (3) and the feed dog (1) is parallel to

the needle plate.

1. Turn the machine pulley to move the feed dog (1) to its

highest position above the needle plate.

2. Tilt back the machine head.

3. Loosen the two set screws (4).

4. Turn the shaft (2) in the direction of the arrow within a

range of 90° with respect to the standard position. (Fig.

[C])

* In order to prevent puckering, lower the front of the

feed dog (1).

* In order to prevent the material from slipping, raise

the front of the feed dog (1).

5. Securely tighten the set screws (4).

* If you would like to tilt the feed dog (1) further, turn the

feed lifting rock bracket stud (5) while carrying out the

above adjustment. (Figure [D])

(Refer to "7-4. Adjusting the feed dog height" on the

previous page for details of this operation.)

* The height of the feed dog (1) will change after the

angle has been adjusted, so it will be necessary to re-

adjust the height of the feed dog (1).

1817M

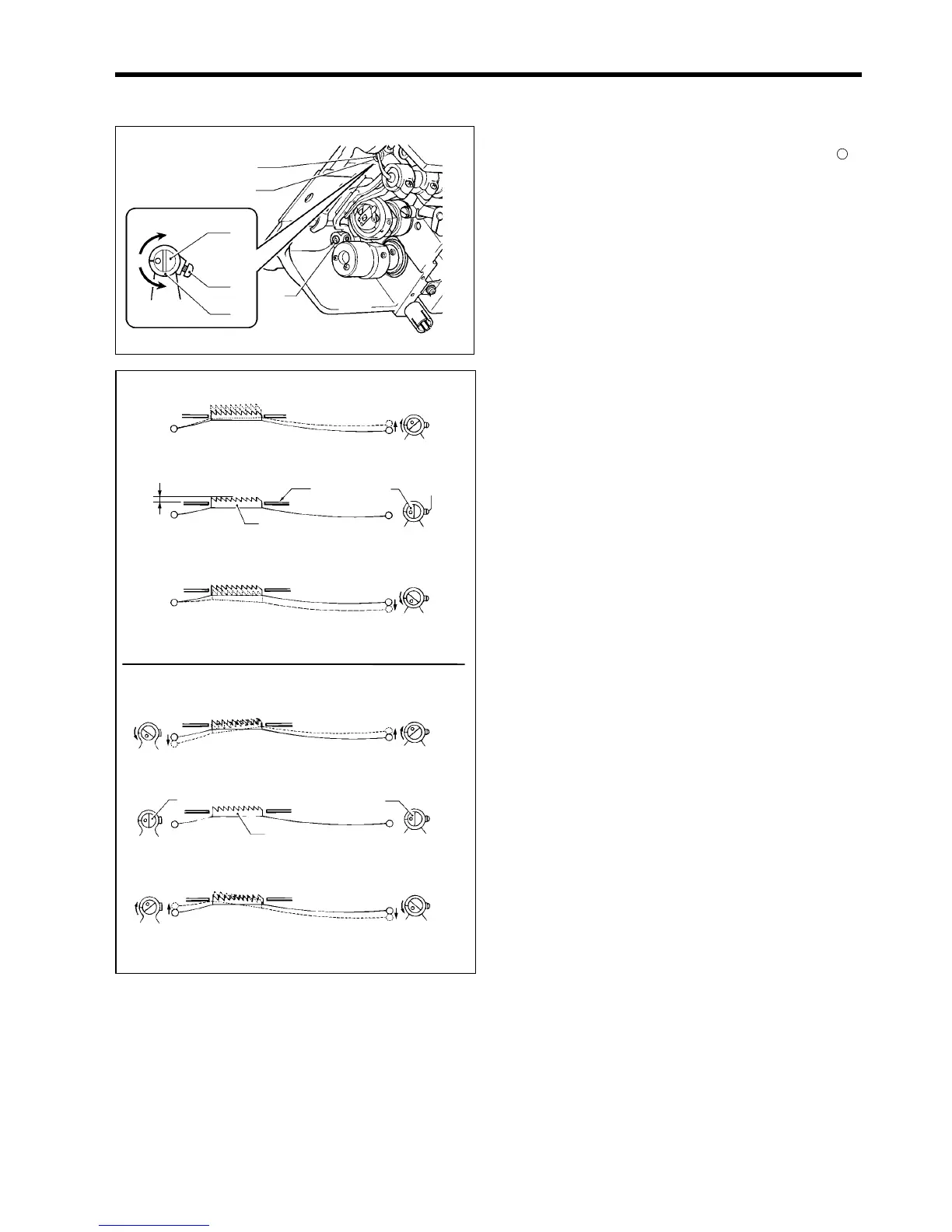

Raise the front

(2)

(4)

(3)

(2)

(3)

(5)

Lower

the front

1818M

1819M

Parallel

Lower the fron

Loading...

Loading...