7. ADJUSTMENTS

SL-710A

70

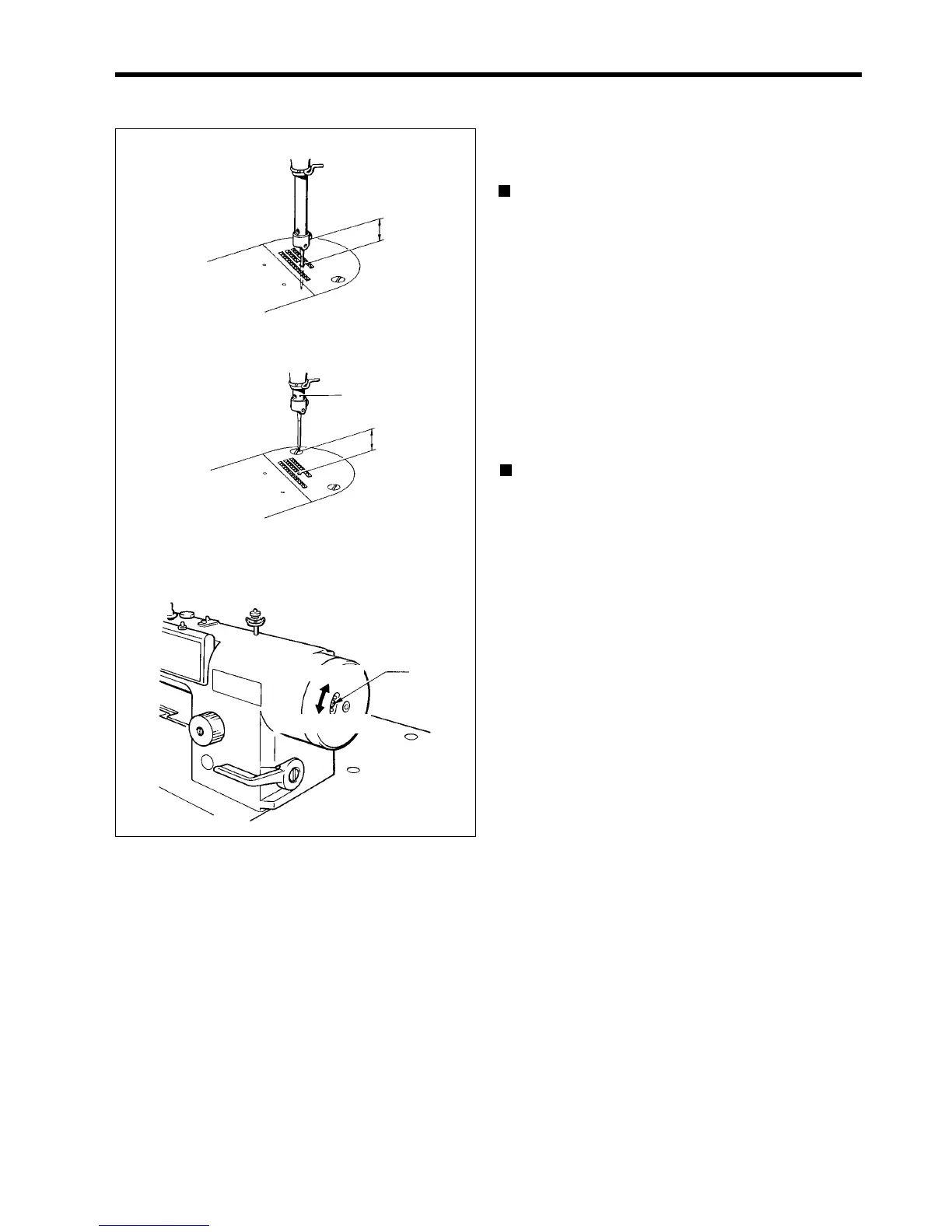

7-11. Synchronizer Adjustment

The synchronizer uses a single element to detect the

needle up stop position. The needle down single is fixed.

Checking method

1. Turn on the power switch.

2. Stop the machine with the needle in the needle down

position.

Check that the distance from the top of the needle

plate to the bottom edge of the needle set screw is 19

- 25 mm at this time.

3. After the thread is trimmed, stop the machine with the

needle in the needle up position.

4. Check that the distance from the top of the needle

plate to the tip of the needle is within the value shown

in the illustration in accordance with the machine

model.

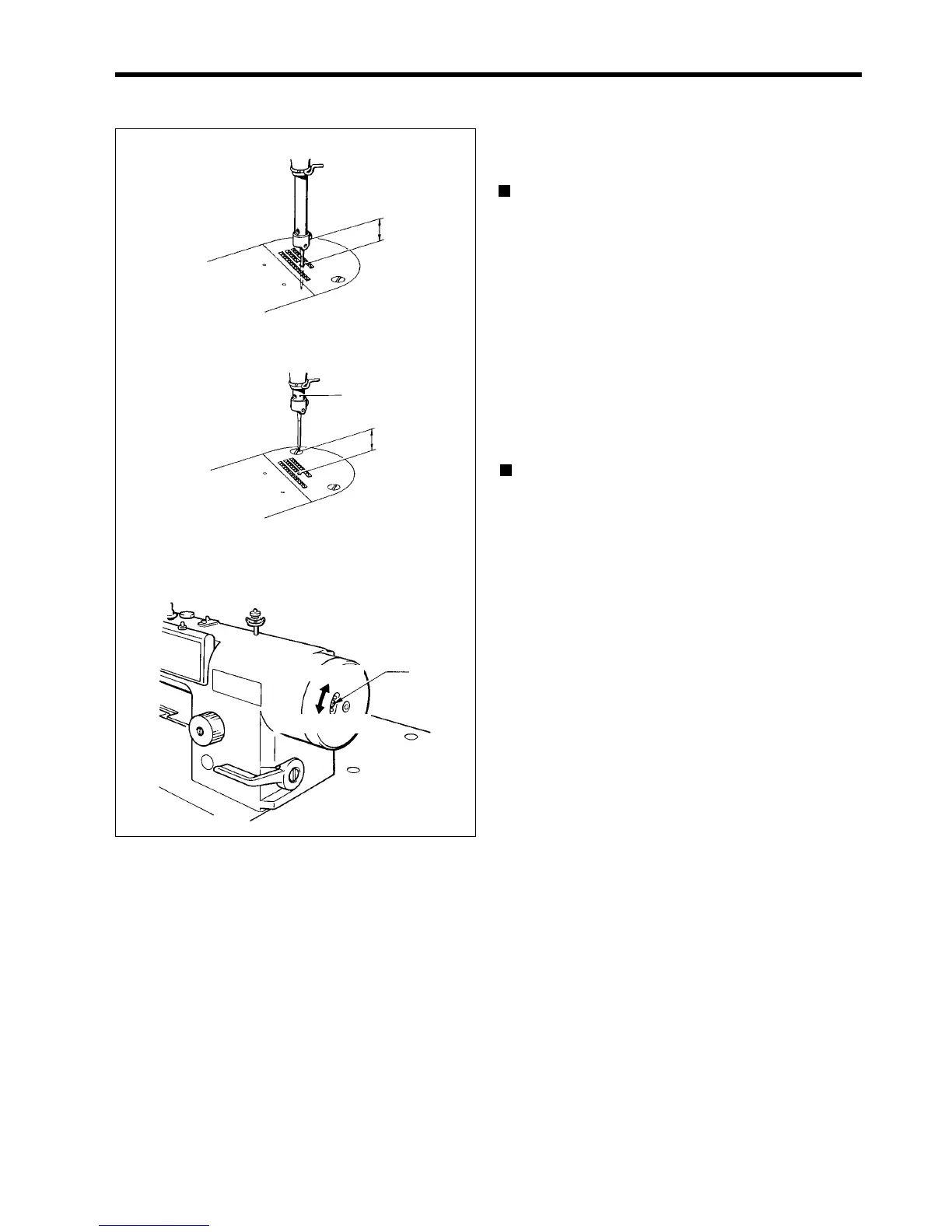

Adjusting the needle up stop position.

1. Turn off the power switch.

2. Loosen the screw (1).

3. Move the screw (1) in the direction of rotation of the

machine pulley to raise the needle bar (2) to a higher

stop position.

Move the screw in the other direction to lower the

needle bar stop position.

4. Securely tighten the screw (1).

Note: Do not turn the pulley while the screw (1) is

loosened, otherwise other parts may become

damaged as a result of the looseness.

0931M

0741M

0932M

(2)

(1)

19 - 25 mm

Needle down position

Needle up position

<-[][]1>

8 - 10.5 mm

<-[][]3>

10 - 12.5 mm

<-[][]5>

12.5 - 15 mm

Becomes lower

Becomes higher

Loading...

Loading...