7. ADJUSTMENTS

SL-710A

71

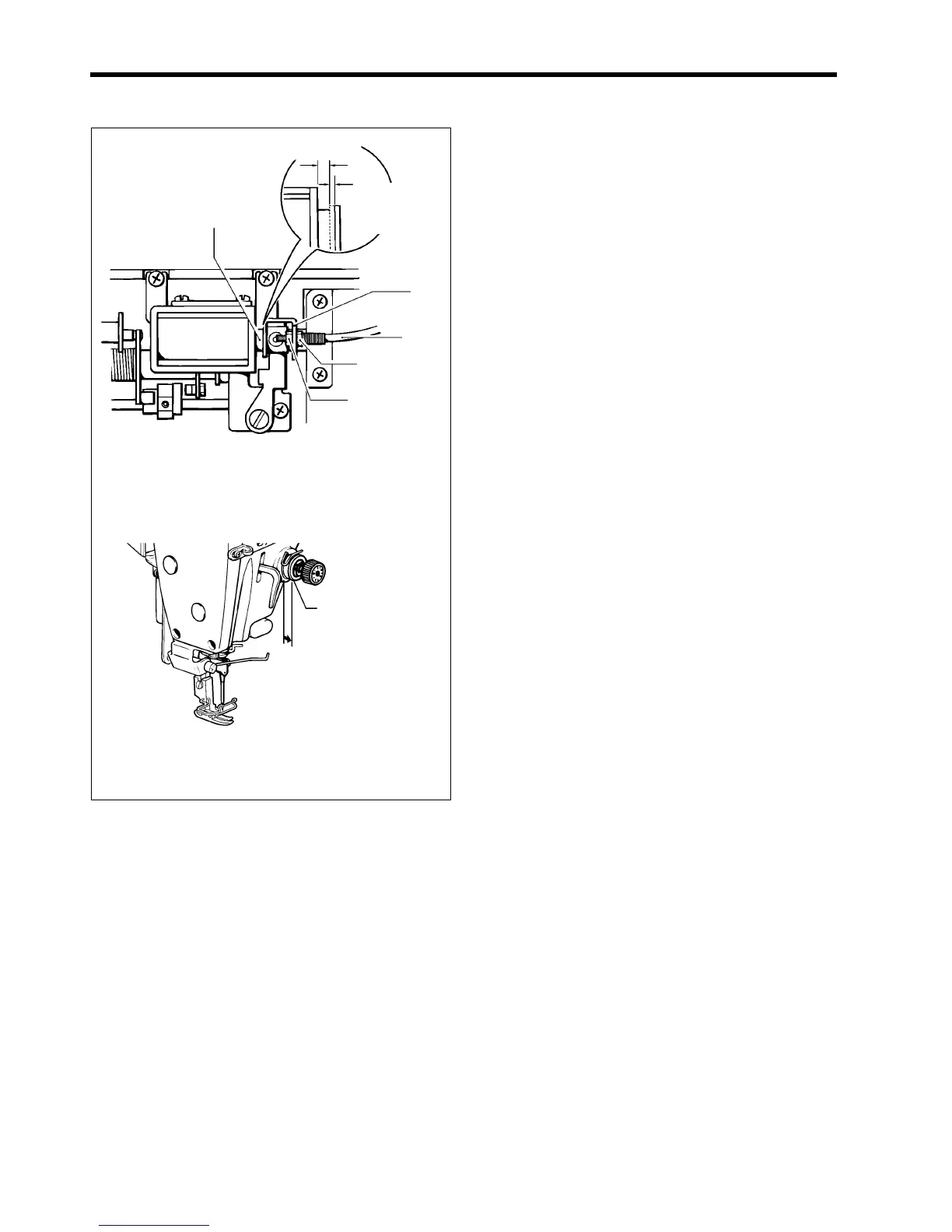

7-12. Adjusting the tension release wire

If the tension discs stay open or if the upper thread pulls

out of the needle after thread trimming, carry out the

following adjustments.

* Lower the presser foot when making these

adjustment.

A. If the upper thread pulls out of the needle

(The tension release wire does not operate

enough during thread trimming)

• When the solenoid plunger (1) is pushed by 2 - 3

mm, the tension discs (2) start opening, and when

it is pushed all the way, the tension discs (2)

should always be open.

• When the solenoid plunger (1) is released, the

tension discs (2) close.

1. Loosen the nuts (3) and (4), and then push the

solenoid plunger (1) by 2 - 3 mm.

2. Tighten the left-side nut (3) until the tension discs (2)

start to open.

3. Check that the tension discs (2) open fully when the

solenoid plunger (1) is pushed all the way, and that the

tension discs (2) close when the solenoid plunger (1)

is released.

4. Tighten the right-side nut (4).

B. If the tension discs stay open

1. Check that the solenoid lever (5) has returned fully.

2. Check that the tension release wire (6) is not

stretched.

3. Adjust using nuts (3) and (4) as described above.

* If adjustment is not possible, adjust the tension of

the tension release wire (6). (Refer to 6-23 on page

55.)

1824M

(1)

(5)

(6)

(4)

(3)

Open

2 - 3 mm

Opening

starts

1795M

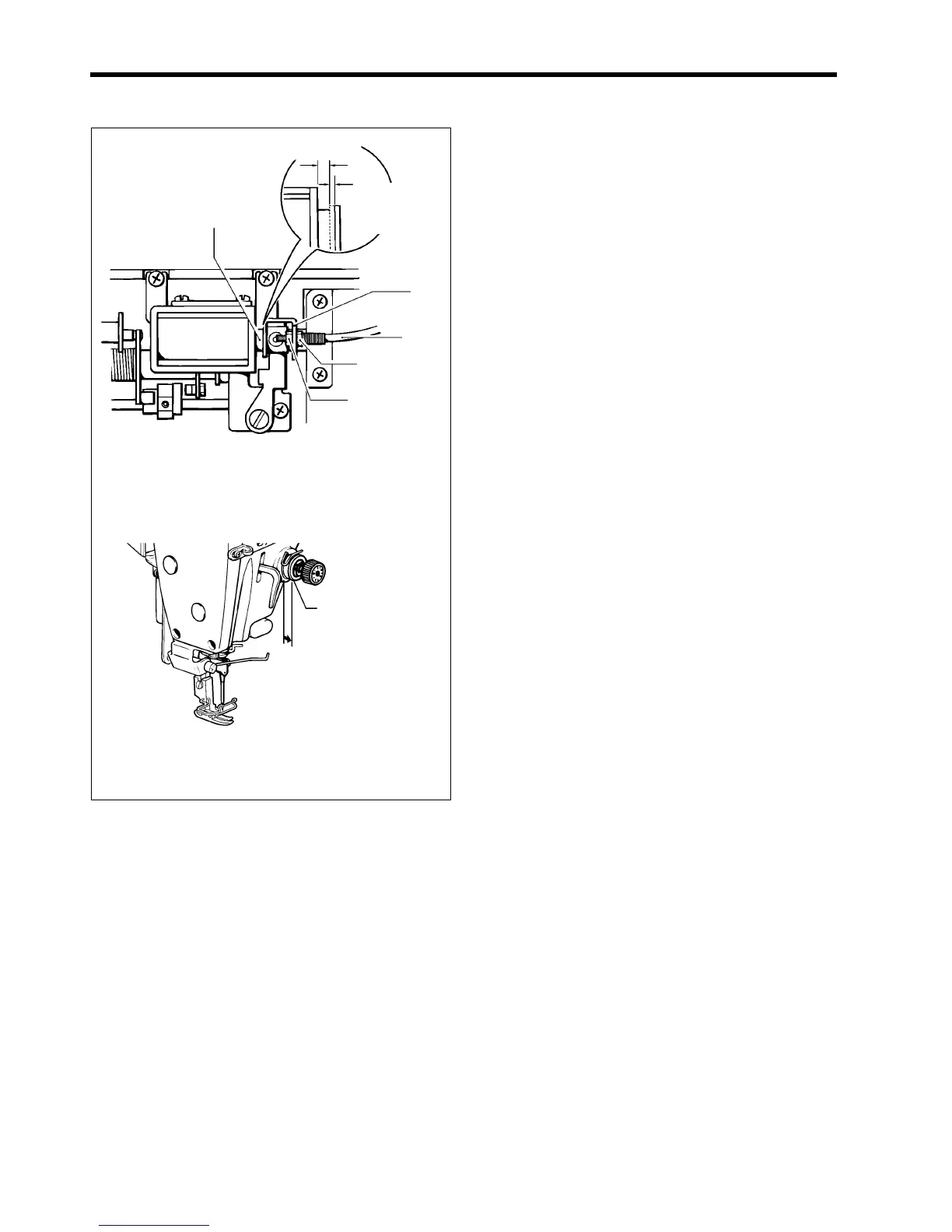

(2)

0.5 - 1 mm

Loading...

Loading...