Chapter 7 Macro TC-32B

2004/01/22 7 - 10 eTCOMNCPR7-1.doc

7

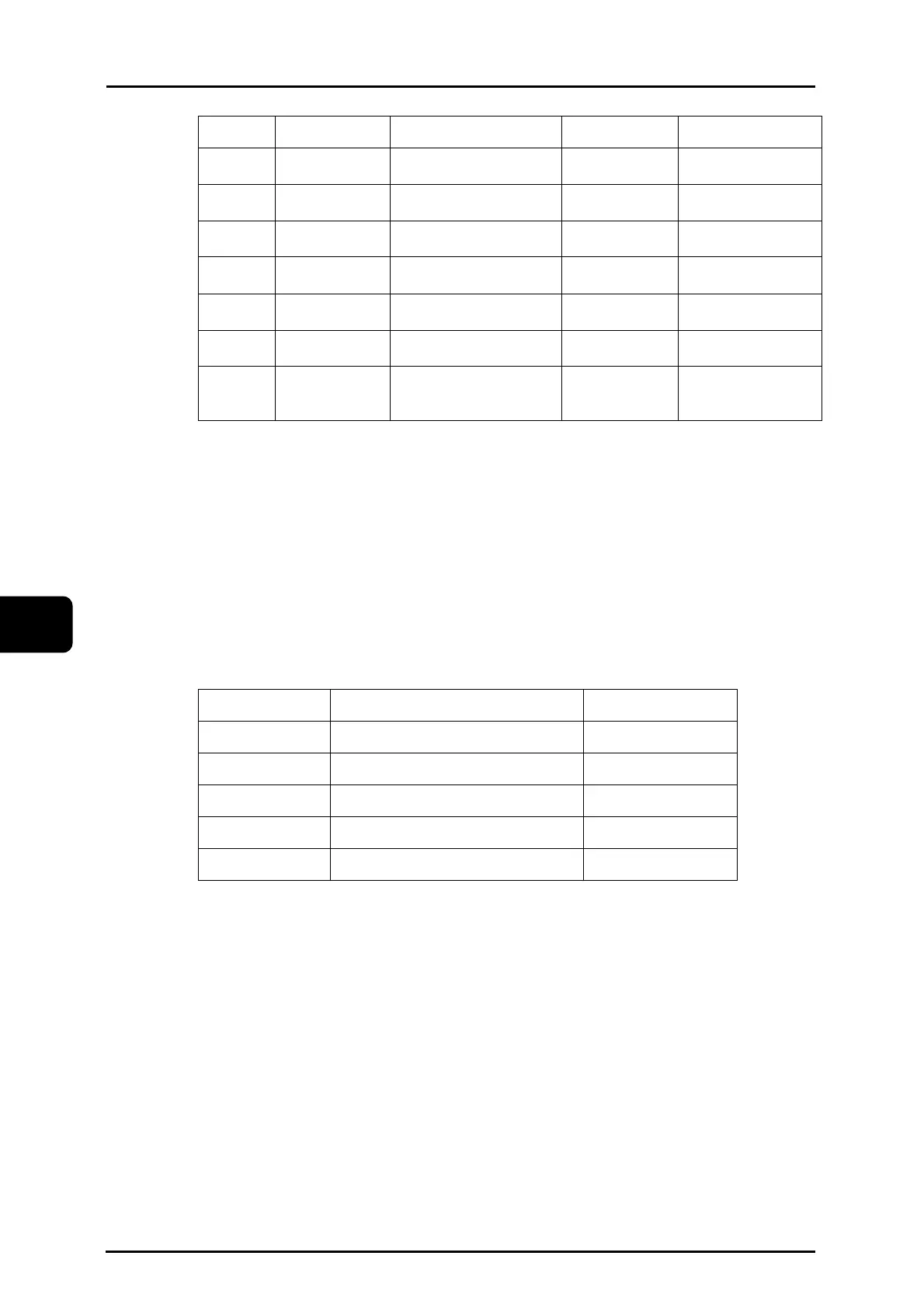

10. Current position

No. Contents Coordinate System Tool offset

Read while

traveling

#5001~

#5008

End point

coordinate

Workpiece coordinate

system

Not included Possible

#5021~

#5028

Current

position

Machine coordinate

system

Included Not possible

#5041~

#5048

Current

position

Workpiece coordinate

system

Included Not possible

#5061~

#5068

Skip

coordinate

Workpiece coordinate

system

Included Possible

#5081~

#5088

Tool length

offset

Not possible

#5101~

#5108

Servo

deviation

Not possible

#5201~

#5208

External

workpiece

coordinate zero

“Not possible” is listed in the “Read while traveling “column for “Current position” tool length

offset” and “servo deviation”. This means that the value is not guaranteed because the value is set

when “Interpretation” is performed.

In the program below, the macro command is executed in the block during interpretation while the

axis travel block is being executed, so the position during travel is read, instead of the position

traveled to in the previous block.

X-10.;

X-10.;

X-10.;

#100=#5021;

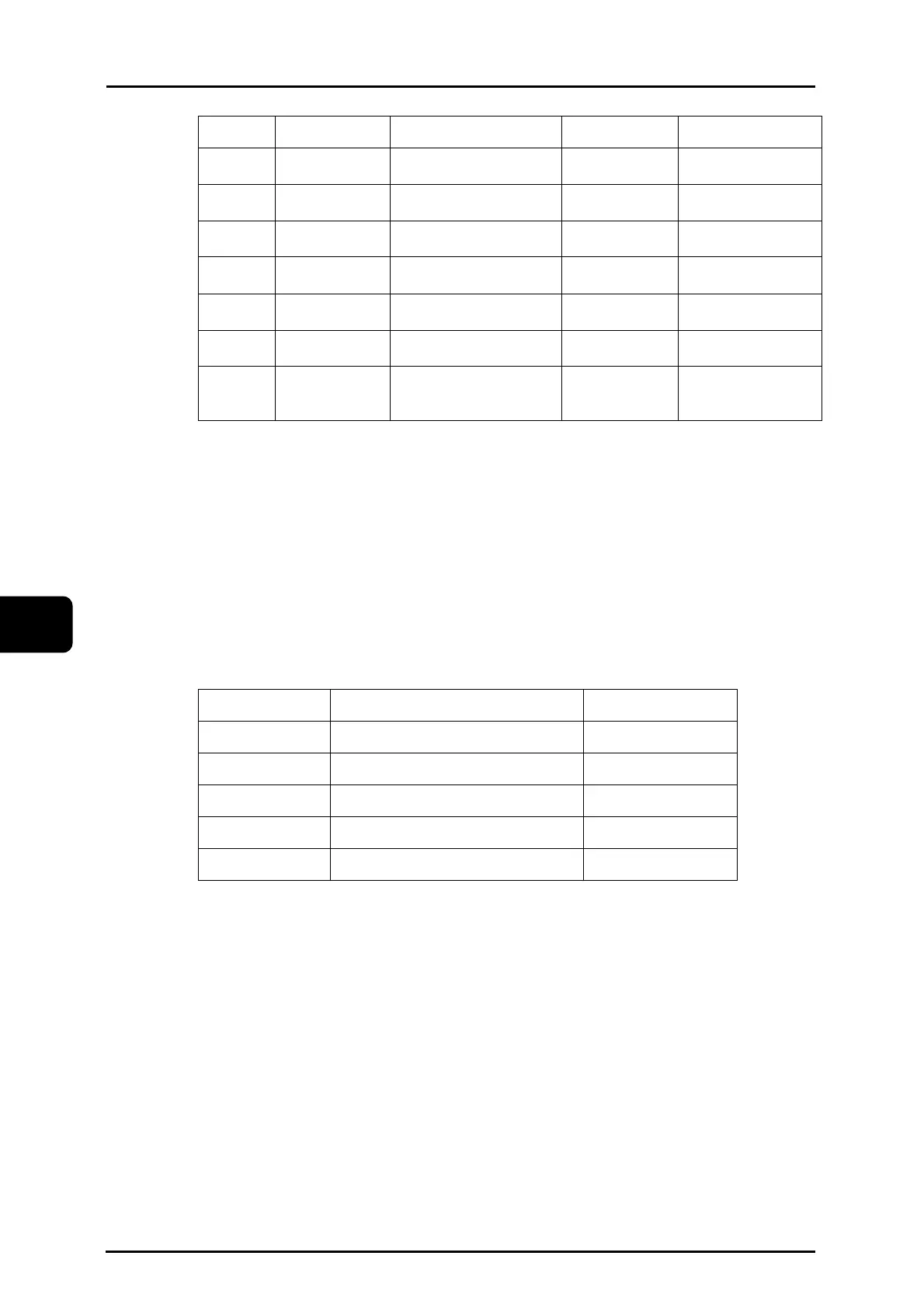

11. ATC tool

Read the tool number that set to the ATC tool screen.

#3700 Spindle R

#3701 Pot 1 R

#3702 Pot 2 R

.. R

.. R

#3750 Pot 50 R

0 : Cap is specified.

1~99 : Tool number set by NC language mode.

1001~1099 : Tool number set by conversation mode

Blank : Non setting

Loading...

Loading...