Visual-ICE™ Cryoablation System

4-9

Screen 4-8. No Gas Connected message

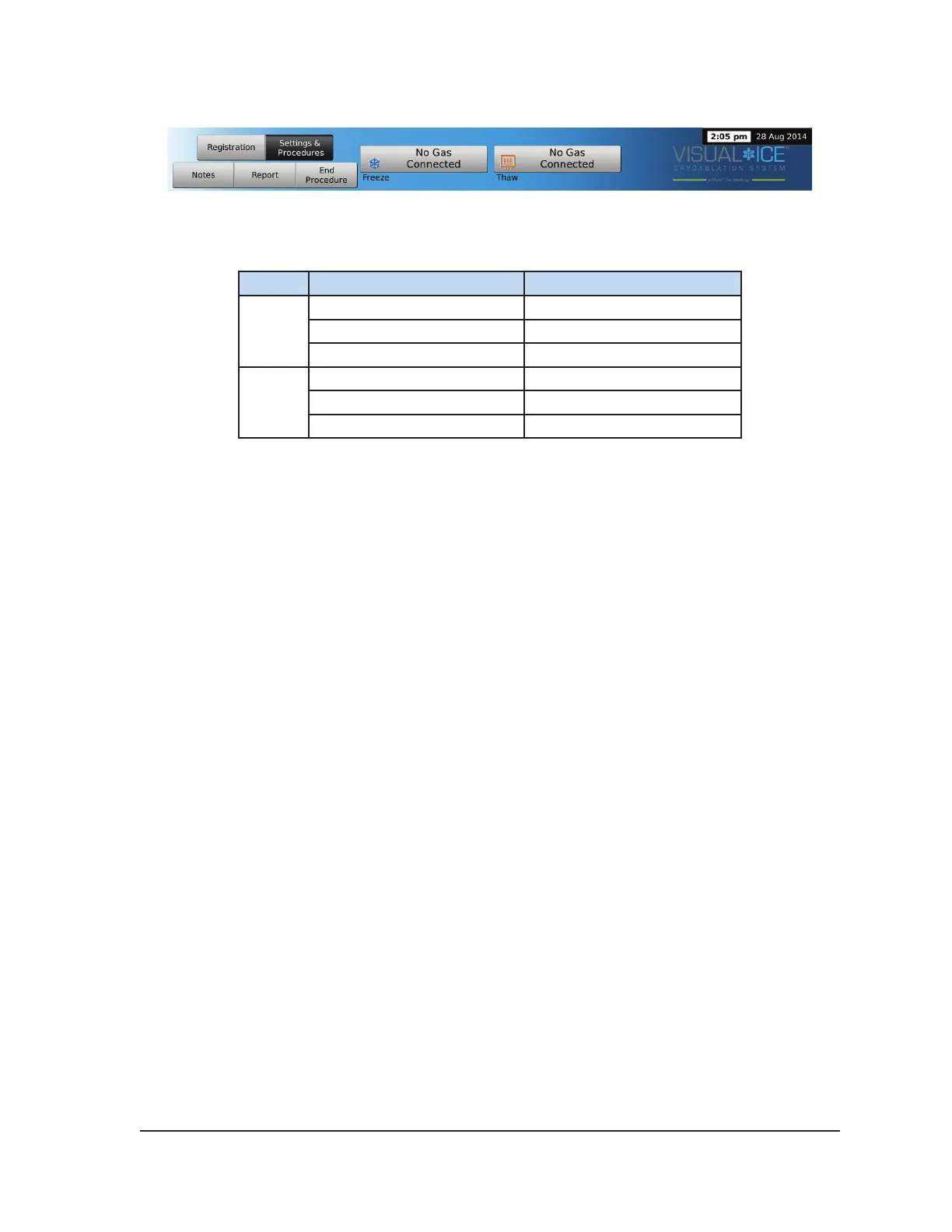

Table 4-2. Working Gas Pressures

Gas Nominal Working Pressure Working Pressure Limits

Argon

3500 psi 3200 – 3800 psi

241 bar 221 – 262 bar

24.1 MPa 22.1 – 26.2 MPa

Helium

2200 psi 1800 – 2500 psi

152 bar 124 – 172 bar

15.2 MPa 12.4 – 17.2 MPa

NOTE: When helium is not connected, active thawing can be conducted with an i-Thaw-capable

cryoablation needle. The system will ow argon gas at 500 psi (34 bar, 3.4 MPa) through the needle

and will energize the internal heating element of the i-Thaw-capable needle when the Thaw button is

pressed.

CAUTION.

• When the gas cylinder pressure falls below the lower working pressure limit, the system

displays an alert message in the Navigation Tool Bar. To ensure optimal performance,

replace a gas cylinder if the pressure falls below the lower working pressure limit.

• Failure to operate the Visual-ICE System within the working pressure limits may aect the

cryoablation procedure.

• If the system produces a continuous hissing sound, verify that the Manual Vent Valve is fully

closed. If the Manual Vent Valve is fully closed and the hissing sounds persists, shut OFF the

system using the power control knob located on the front of the system (Figure 2-1). Close

the gas supplies using the cylinder valves. Contact Galil Medical Customer Service.

4.1.3 Gas Line Flushing

After argon is connected and the gas lines pressurized, the Visual-ICE System automatically

conducts gas line ushing to reduce potential gas line contaminants.

• When argon is connected to the system and the gas lines pressurized prior to pressing Start

Procedure, the automated ushing will occur before the Procedure Screen is displayed.

• When the Procedure Screen is displayed before the argon is connected, automated ushing

will occur after the connected gas pressurizes the lines.

During the ushing procedure, a sequence of gas ow, followed by an idle period, will occur three

times.

• Gas will ow for 3 seconds.

• An idle period of 30 seconds will follow the gas ow.

• The automated ushing process will be completed in ~ 90 seconds.

As the system conducts gas line ushing, the screen displays Optimizing Lines.

Loading...

Loading...